Furniture plywood, the unsung hero of countless homes and cherished pieces, embodies a delicate balance of strength, beauty, and workability. This engineered wood panel, often hidden beneath veneers and finishes, provides the structural integrity and smooth canvas upon which furniture dreams are built. This comprehensive guide delves into the world of furniture plywood, unraveling its unique characteristics, diverse types, selection secrets, and its enduring appeal for both seasoned artisans and passionate DIY enthusiasts.

What Makes Furniture Plywood Special?

Furniture plywood stands apart from its construction-grade counterparts, boasting features tailored for the demanding world of furniture making and cabinetry. It’s not just about structural support; it’s about creating pieces with finesse and longevity:

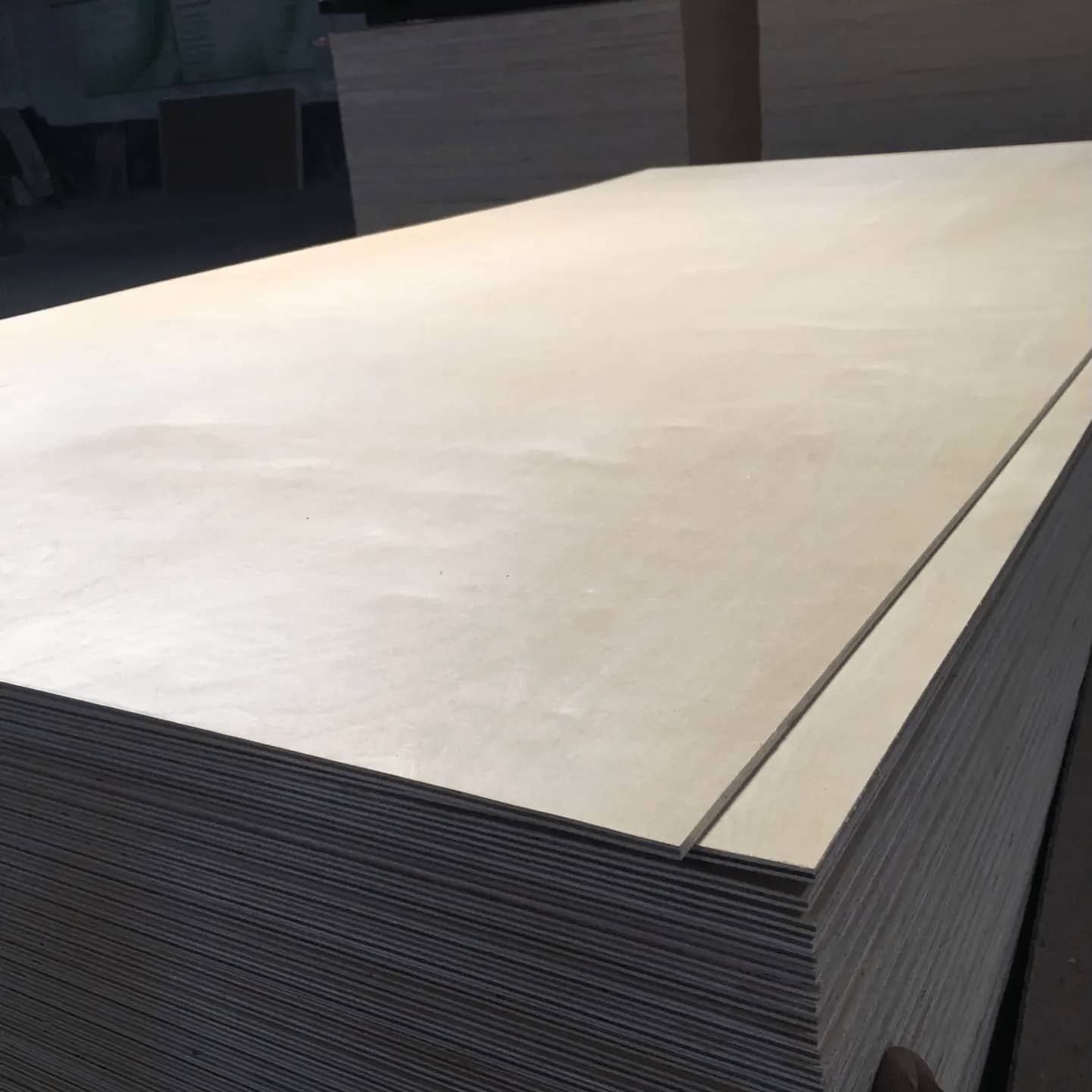

- Smooth, Consistent Surface: Unlike the rough, often blemished surface of construction plywood, furniture plywood features a sanded face veneer, often a hardwood species chosen for its visual appeal and smooth finish. This provides an ideal canvas for staining, painting, or veneering, ensuring a polished and professional look that elevates the final piece.

- Dimensional Stability: Furniture pieces demand precision and longevity. Furniture plywood answers this call with exceptional dimensional stability, resisting warping, twisting, or cupping over time, even in varying humidity levels. This ensures drawers glide smoothly, doors align perfectly, and the furniture retains its structural integrity for years to come, a testament to its quality.

- Variety of Core Options: Furniture plywood offers a spectrum of core options, each influencing the panel’s weight, strength, cost, and workability. This allows for customization based on the project’s specific needs and budget. Whether you need the robust strength of hardwood for a dining table or the lightweight affordability of softwood for a decorative shelf, there’s a furniture plywood option to match.

- Edge Banding Compatibility: The layered edges of plywood, while structurally sound, often require a finishing touch for a refined aesthetic. Furniture plywood is designed for seamless integration with edge banding, a thin strip of wood veneer or plastic applied to the edges. This conceals the plywood’s construction and creates a refined, seamless look, mimicking the appearance of solid wood while offering the advantages of plywood’s stability.

Navigating the World of Furniture Plywood: Types and Grades

Understanding the nuances of furniture plywood types and grading systems is crucial for selecting the right material for your project’s demands, ensuring both beauty and functionality:

Common Core Types:

| Core Type | Description | Advantages | Considerations |

|---|---|---|---|

| Hardwood Plywood | The gold standard for furniture making, featuring hardwood veneers throughout for exceptional strength, stability, and screw-holding ability. This core type is favored for high-end furniture, cabinetry, and projects demanding longevity and a refined aesthetic. | Durable, stable, works exceptionally well with screws and fasteners, takes finishes beautifully, often showcasing attractive wood grain patterns. | More expensive than softwood plywood, weight can be a consideration for large projects, requires sharp tools and careful handling to prevent chipping during cutting. |

| Softwood Plywood | A more budget-friendly option, typically using softwood veneers for the core layers and hardwood veneers for the face and back. Offers good strength and stability for lighter-duty furniture applications like shelves, headboards, or interior drawer components. | Lighter weight than hardwood plywood, more affordable, suitable for many furniture projects, readily available in various sizes and thicknesses. | May not be as strong or dimensionally stable as hardwood plywood, screw-holding ability may be slightly lower, requires careful selection of face veneer grade for a smooth finish. |

| MDF Core Plywood | Features a core made from Medium Density Fiberboard (MDF), a highly stable and consistent engineered wood product. Offers exceptional smoothness and stability, ideal for painted or veneered surfaces where a pristine finish is paramount, such as cabinets, doors, and modern furniture designs. | Extremely smooth surface, highly stable, resists warping and twisting even in humid environments, takes paint and veneer exceptionally well, offering a sleek, modern aesthetic. | Not as strong as hardwood plywood, less suitable for heavy-duty applications, moisture resistance can be a concern if the MDF core is exposed, requires proper edge sealing to prevent moisture absorption. |

| Particleboard Core Plywood | A budget-friendly option with a core made from particleboard, another engineered wood product. Offers a smooth surface and decent stability, suitable for less demanding furniture projects like ready-to-assemble furniture, interior components, or projects where the surface will be fully covered. | Affordable, smooth surface suitable for painting or veneering, readily available in various sizes, lightweight and easy to work with. | Not as strong or moisture-resistant as hardwood or MDF core plywood, screw-holding ability can be lower, may not be suitable for high-end furniture or projects requiring exceptional strength, can be prone to sagging over time in large unsupported spans. |

| Combination Core Plywood | Combines different core materials, such as hardwood and MDF, to achieve specific performance characteristics and cost targets. This allows for tailored solutions, balancing strength, stability, and affordability. | Offers a balance of strength, stability, and cost-effectiveness, customizable to project needs, allows for optimized material use. | Performance characteristics vary depending on the specific core combination, consult manufacturer specifications to determine suitability for your project, availability may be more limited than single-core types. |

Understanding Plywood Grades:

Grading systems for furniture plywood focus primarily on the face veneer, as this is the visible surface that determines the panel’s aesthetic appeal. Common grading terms include:

- A-Grade: Represents the highest quality face veneer, with a smooth, uniform surface, minimal color variation, and virtually no blemishes or imperfections. Ideal for high-end furniture, cabinetry, and projects where a flawless finish is desired, showcasing the natural beauty of the wood grain.

- B-Grade: Allows for slight imperfections in the face veneer, such as minor color variations, small knots, or filled repairs. Still suitable for many furniture applications, especially when the surface will be painted or covered with a veneer, offering a balance of quality and cost-effectiveness.

- C-Grade: Permits more noticeable imperfections, such as larger knots, color variations, or filled repairs. Often used for utility furniture, shop projects, or applications where aesthetics are less critical, or where the imperfections can add a rustic charm.

- D-Grade: Represents the lowest grade, allowing for significant imperfections and variations in the face veneer. Typically used for structural applications or projects where the surface will be completely covered, not recommended for visible furniture components.

Note: Plywood is often graded using a letter combination to indicate the quality of both the face and back veneers. For example, “AB plywood” has an A-grade face veneer and a B-grade back veneer.

Choosing the Right Furniture Plywood: Factors to Consider

Selecting the ideal furniture plywood for your project involves carefully considering several key factors to ensure both aesthetic and functional success:

- Project Requirements: The intended use of the furniture dictates the plywood’s required strength, stability, and moisture resistance. Heavy-duty furniture like bookshelves or dining tables demand the robust nature of hardwood plywood, while lighter-duty pieces like nightstands or decorative shelves might allow for softwood plywood or MDF core options. Consider the weight the furniture will bear, its exposure to humidity, and the level of structural support needed.

- Budget Considerations: Furniture plywood prices vary significantly based on core type, veneer grade, and thickness. Hardwood plywood, especially with A-grade veneers, commands a premium price, while softwood plywood and lower veneer grades offer more budget-friendly alternatives. Balance your desired quality and performance with your project’s financial constraints.

- Aesthetic Preferences: The visual appeal of the furniture plays a crucial role in its overall impact. Consider the desired wood species, grain pattern, and finish. For stained finishes, choose plywood with an attractive face veneer that complements your design, highlighting the natural beauty of the wood. For painted finishes, MDF core plywood offers an exceptionally smooth and consistent surface, ideal for a modern, sleek look.

- Environmental Impact: Sustainable forestry practices and responsible manufacturing are essential considerations for environmentally conscious creators. Look for plywood certified by organizations like the Forest Stewardship Council (FSC), which ensures the wood comes from responsibly managed forests, supporting a healthy ecosystem and responsible resource management.

- Workability and Skill Level: Different plywood types exhibit varying degrees of workability. Hardwood plywood, while strong and durable, can be more challenging to cut and shape, especially thicker sheets, requiring sharp tools and careful techniques. Softwood plywood and MDF core plywood tend to be more forgiving for beginners, allowing for easier cutting and shaping.

Unlocking the Potential: Working with Furniture Plywood

While furniture plywood offers numerous advantages, understanding some key techniques can elevate your craftsmanship and ensure professional-grade results, transforming your furniture from good to exceptional:

- Precise Cutting: Use sharp saw blades specifically designed for plywood to prevent chipping and splintering. Carbide-tipped blades with a high tooth count are ideal for clean, precise cuts, preserving the integrity of the veneer and ensuring smooth edges. Support the plywood adequately during cutting to minimize vibrations and maintain accuracy, using clamps or a saw guide for optimal results.

- Edge Banding Mastery: Edge banding is often the hallmark of professional-looking furniture, concealing the plywood layers and creating a seamless, refined appearance. Use a high-quality edge banding material that complements the plywood’s face veneer, matching the wood species and grain pattern for a cohesive look. Apply edge banding with a dedicated edge banding machine for a factory-like finish or a household iron for smaller projects, ensuring even pressure and heat distribution. Trim the excess edge banding flush with the plywood surface for a seamless look, using a flush-trim router bit or a sharp chisel for a precise finish.

- Surface Preparation: Sanding is crucial for achieving a smooth and flawless finish, preparing the surface for staining, painting, or veneering. Start with a coarser grit sandpaper to remove any imperfections or glue residue, gradually progressing to finer grits for a polished surface. Sand in the direction of the wood grain to avoid scratches, and use a sanding block for even pressure distribution.

- Finishing Touches: Whether you choose to stain, paint, or veneer your furniture, proper surface preparation is paramount for a professional-looking result. Apply a primer or sealer to the plywood before finishing to ensure even absorption and prevent blotchiness, creating a uniform base for the final finish. Use high-quality finishes and apply them in thin, even coats for a smooth and durable finish, following the manufacturer’s instructions for drying times and application techniques.

Furniture Plywood FAQs: Your Questions Answered

Q1: Can I use furniture plywood for outdoor furniture?

A: While furniture plywood is generally intended for indoor use, some types can be suitable for outdoor applications with proper precautions. Opt for exterior-grade plywood with a marine-grade core, as these are specifically designed to withstand moisture and humidity. Additionally, protect the plywood with a high-quality exterior-grade primer, paint, or sealant to further enhance its moisture resistance and UV protection. Regular maintenance and protective coatings will be crucial for longevity in outdoor environments.

Q2: What is the best way to finish furniture plywood for a natural wood look?

A: To showcase the natural beauty of furniture plywood, consider these finishing options:

- Staining: Choose a stain that complements the wood species of the face veneer. Apply the stain evenly following the manufacturer’s instructions, and allow it to dry completely.

- Clear Coating: After staining or for a natural, unfinished look, apply a clear protective coating like polyurethane, varnish, or lacquer. This will protect the wood from scratches, spills, and UV damage.

- Oil Finish: For a natural, low-sheen finish that enhances the wood’s grain and color, consider an oil finish like tung oil or linseed oil. Oil finishes penetrate the wood, providing protection and a warm, natural patina.

Q3: How do I choose the right thickness of furniture plywood for my project?

A: Plywood thickness is crucial for structural integrity and depends on the intended use and load-bearing requirements:

- Thinner Sheets (1/4″ – 1/2″): Suitable for lightweight applications like drawer bottoms, cabinet backs, or decorative elements.

- Medium Thickness (3/4″): A versatile choice for many furniture projects, including cabinets, shelves, tabletops, and desks.

- Thicker Sheets (1″ or more): Ideal for heavy-duty applications like tabletops, desks, bookshelves, or structural components requiring exceptional strength and stability.

Q4: Can I use regular plywood for furniture making?

A: While you can technically use regular plywood for furniture, it’s not always the ideal choice. Construction-grade plywood often has a rougher surface, may have more imperfections in the face veneer, and might not be as dimensionally stable as furniture plywood. If you do use regular plywood, opt for higher grades with smoother veneers and consider using edge banding to conceal the plywood layers.

Q5: What are the advantages of using furniture plywood over solid wood for furniture making?

A: Furniture plywood offers several advantages over solid wood:

- Stability: Plywood is less prone to warping, twisting, or cracking than solid wood, especially in varying humidity levels.

- Affordability: Furniture plywood can be more cost-effective than solid wood, especially for larger projects.

- Availability: Plywood is readily available in large sheets, making it suitable for projects requiring large, continuous surfaces.

- Versatility: Plywood comes in various core types and veneer grades, offering flexibility to meet specific project needs and budgets.