Plywoods, seemingly simple sheet material, has become a cornerstone of countless industries and applications. Its versatility, strength, and affordability have made it an indispensable component in construction, furniture making, packaging, and a myriad of other sectors. This comprehensive exploration delves into the diverse world of plywoods applications, revealing its remarkable adaptability and enduring relevance in today’s material landscape.

Understanding the Essence of Plywoods: Strength in Layers

Plywood’s remarkable properties stem from its unique construction, which sets it apart from solid wood and makes it suitable for a wide range of demanding applications. Unlike solid wood, which can be prone to warping, splitting, and inconsistencies, plywoods are engineered for strength and stability. It is manufactured by layering thin sheets of wood veneer, called plies, together with the grain of each layer running perpendicular to the adjacent one. This cross-graining technique, where each layer counteracts the weaknesses of its neighbors, is bonded together with strong adhesives under heat and pressure. The result is a panel that exhibits exceptional strength, dimensional stability, and resistance to moisture, making it ideal for applications where durability and reliability are paramount.

Here’s a closer look at what makes plywood a superior choice:

- Dimensional Stability: Plywood’s cross-grained construction minimizes expansion and contraction in response to changes in humidity and temperature, making it far more stable than solid wood. This stability ensures that plywoods panels retain their shape and integrity over time, preventing warping, twisting, and shrinking, even in challenging environments.

- Exceptional Strength: The alternating grain direction in plywoods distributes stress evenly across the panel, making it significantly stronger than solid wood of comparable thickness. This exceptional strength-to-weight ratio makes plywoods ideal for structural applications where it needs to bear heavy loads or resist bending and breaking.

- Lightweight yet Durable: Despite its strength, plywood remains relatively lightweight, making it easy to handle, transport, and install. This combination of strength and manageability makes plywood a favorite among builders, contractors, and DIY enthusiasts alike.

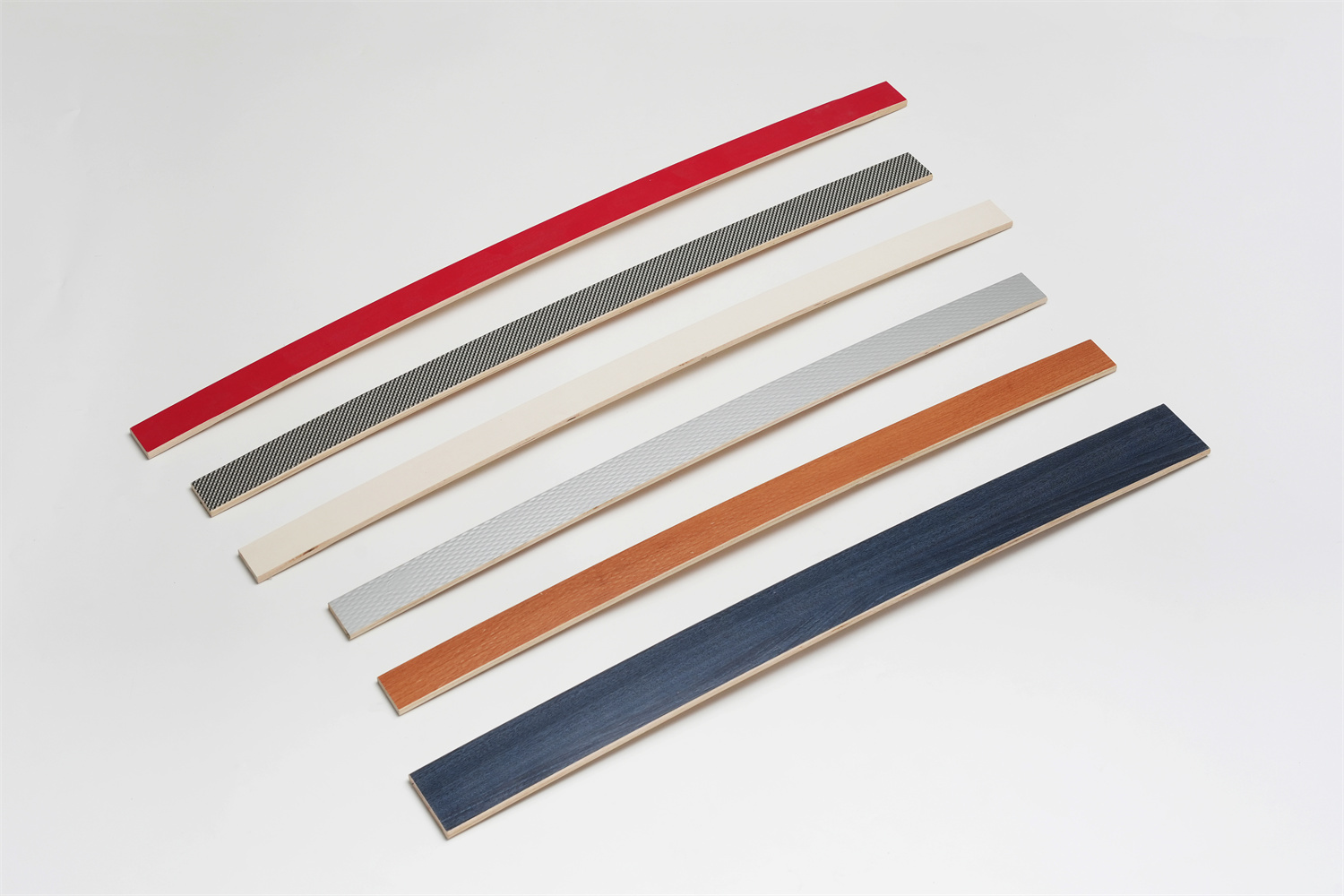

- Versatile and Adaptable: Plywoods can be easily cut, shaped, and finished to meet a wide range of design and structural requirements. Its smooth surface readily accepts paints, stains, and laminates, allowing for endless design possibilities.

Construction: The Backbone of Buildings

Plywood’s strength, affordability, and ease of use have made it a staple in the construction industry for decades. From the structural framework that forms the skeleton of a building to the decorative finishes that bring it to life, plywood plays a pivotal role in shaping the buildings we inhabit. Its versatility is evident in its wide-ranging applications, from providing structural support to enhancing aesthetics.

Structural Applications:

- Sheathing: Plywoods are commonly used as sheathing for walls, roofs, and floors, providing a structural skin that adds strength and rigidity to the building frame. It acts as a racking restraint, preventing the walls from twisting or collapsing under lateral forces like wind loads or seismic activity. Plywood sheathing also provides a stable and consistent surface for attaching cladding materials like siding, shingles, or exterior insulation.

- Subflooring: Plywood subfloors provide a smooth, level, and durable base for installing finished flooring materials like hardwood, tile, or carpet. Its strength and stiffness prevent sagging and deflection, ensuring a long-lasting and squeak-free floor. Plywood subfloors also offer excellent load-bearing capacity, making them suitable for high-traffic areas.

- Concrete Formwork: Plywood’s smooth surface and dimensional stability make it ideal for creating concrete forms, which are temporary molds used to shape and support concrete until it hardens. The smooth surface of the plywoods ensures a clean and consistent finish on the concrete, while its dimensional stability prevents warping or bulging under the pressure of the wet concrete.

- I-Beams and Headers: Engineered wood products like LVL (Laminated Veneer Lumber), a type of structural plywoods, are used to create strong and dimensionally stable beams and headers for supporting roofs and floors. LVL beams and headers are known for their high strength-to-weight ratio, allowing for longer spans and greater design flexibility compared to traditional lumber.

Interior Applications:

- Wall Paneling: Plywoods can be used as a cost-effective and durable wall covering, offering a variety of finishes and textures to enhance interior aesthetics. Its smooth surface can be painted, stained, or covered with wallpaper, providing endless design possibilities. Plywoods paneling can also be used to create w Wainscoting, a decorative wall treatment that adds a touch of elegance and sophistication.

- Ceiling Linings: Plywoods ceilings provide a clean, finished look while concealing ductwork, wiring, and other ceiling infrastructure. Plywoods ceiling panels can be installed directly to ceiling joists or suspended from a grid system, offering design flexibility and ease of installation. They can be painted or stained to match any décor.

- Built-in Furniture and Cabinetry: Plywoods are a popular choice for building cabinets, shelves, and other built-in furniture due to its strength, stability, and affordability. Its ability to hold screws and other fasteners securely makes it ideal for constructing sturdy and long-lasting furniture pieces. Plywood’s smooth surface also takes well to various finishes, allowing you to achieve the desired look for your custom furniture.

Furniture Making: Crafting Comfort and Style

Plywood’s versatility extends beyond construction, finding a welcoming home in the world of furniture making. Its strength, affordability, and ease of working make it an ideal material for crafting a wide range of furniture pieces, from simple shelves to intricate designs. Designers and furniture makers appreciate plywood for its ability to bring their creative visions to life while offering durability and affordability.

Common Applications:

- Cabinets and Shelving: Plywood’s strength and stability make it ideal for constructing cabinets, bookshelves, and other storage solutions that can withstand heavy loads and frequent use. Its smooth surface provides an ideal base for applying various finishes, allowing you to create furniture pieces that complement any décor.

- Tables and Desks: Plywoods tabletops and desktops offer a durable and affordable surface that can be easily customized with various finishes. Its resistance to scratches, dents, and moisture makes it suitable for everyday use, while its ability to be shaped and edged allows for endless design possibilities.

- Chairs and Seating: Plywoods can be molded and shaped to create comfortable and stylish chairs, benches, and other seating options. Its strength and flexibility make it possible to create ergonomic designs that provide ample support and comfort. Plywoods chairs can be upholstered with fabric or leather for added comfort and style.

- Beds and Headboards: Plywoods are used to create sturdy bed frames, headboards, and platform beds, offering a cost-effective alternative to solid wood. Its strength ensures that the bed frame can support the weight of the mattress and occupants without sagging or wobbling. Plywoods headboards can be easily customized with paint, fabric, or other decorative elements to match your bedroom décor.

Advantages in Furniture Making:

- Cost-Effectiveness: Plywoods offer a more affordable alternative to solid wood, especially for large furniture pieces where the cost of solid wood can be prohibitive. This affordability makes it possible to create high-quality furniture pieces without breaking the bank.

- Design Flexibility: Plywoods can be easily cut, shaped, and molded to create a wide range of designs, from simple to intricate. Its versatility allows designers to push the boundaries of furniture design, creating unique and eye-catching pieces that would be difficult or impossible to achieve with solid wood.

- Durability and Longevity: Plywood’s layered construction makes it resistant to warping, cracking, and splitting, ensuring the longevity of furniture pieces. Unlike solid wood, which can be susceptible to these issues over time, plywoods maintain its structural integrity, ensuring that your furniture pieces remain beautiful and functional for years to come.

Packaging and Transportation: Protecting Goods in Transit

Plywood’s strength, durability, and moisture resistance make it a reliable choice for protecting goods during shipping and storage. Its ability to withstand impact, stacking, and environmental factors ensures that products arrive at their destination safely and securely, making it an essential material in the logistics and transportation industries.

Common Applications:

- Crates and Boxes: Plywood crates and boxes provide robust protection for heavy or fragile items during shipping. Their strength and rigidity help to distribute weight evenly and prevent crushing, while their moisture resistance protects contents from damage caused by humidity or spills. Plywood crates and boxes can be custom-built to accommodate items of various shapes and sizes, ensuring a snug and secure fit.

- Pallets: Plywood pallets are a durable and reusable platform for stacking and transporting goods. They provide a stable base for securing goods during transit and can be easily lifted and moved using forklifts or pallet jacks. Plywood pallets are available in standard sizes to facilitate efficient loading and unloading of goods in warehouses and shipping containers.

- Shipping Containers: Plywood is used in the construction of shipping containers, providing structural integrity and protection from the elements. Its strength and durability help containers withstand the stresses of stacking, lifting, and transportation, while its moisture resistance protects the contents from damage caused by rain, humidity, or sea spray.

Advantages in Packaging:

- Strength and Durability: Plywood can withstand the rigors of shipping, including impact, vibration, and stacking. Its layered construction and strong adhesives ensure that it can handle rough handling during loading, unloading, and transportation, protecting the contents from damage.

- Moisture Resistance: Plywood’s layered construction and available treatments provide protection against moisture damage. This is particularly important for goods that are sensitive to humidity or that may be exposed to moisture during transit, such as electronics, food products, and pharmaceuticals.

- Customizability: Plywood can be cut and shaped to create custom packaging solutions for specific products. This allows businesses to optimize their packaging for efficiency, ensuring that products are protected while minimizing material waste and shipping costs.

Other Notable Applications: A Testament to Versatility

Beyond its prominent roles in construction, furniture making, and packaging, plywood’s versatility shines in a myriad of other applications, demonstrating its adaptability and enduring relevance across diverse industries. Its unique properties make it an attractive material for applications where strength, durability, and affordability are paramount.

- Automotive Industry: Plywood is used for flooring, side panels, and interior components in vans, trucks, and recreational vehicles. Its lightweight yet durable nature makes it ideal for these applications, where weight reduction is crucial for fuel efficiency. Plywood’s ability to be shaped and molded also makes it suitable for creating contoured surfaces and ergonomic designs.

- Marine Applications: Marine-grade plywood, treated to withstand moisture and harsh marine environments, is used for boat building, docks, and other marine structures. Marine-grade plywood is typically made from durable hardwoods like Douglas fir or Western Larch and treated with water-resistant glues and preservatives to prevent rot, decay, and marine borer infestation.

- Signage and Displays: Plywood’s smooth surface and ease of finishing make it ideal for creating signs, displays, and exhibition booths. It can be easily painted, printed on, or covered with vinyl graphics to create eye-catching signage for businesses, events, and retail spaces.

- Hobbies and Crafts: Plywood is a popular material for hobbyists and crafters, used for everything from model building to laser cutting and engraving. Its affordability, ease of working, and availability in various thicknesses make it a versatile material for a wide range of creative projects.

Choosing the Right Plywood: Factors to Consider

With its vast array of applications, it’s essential to select the right type of plywood for your specific needs. Consider these factors when making your selection to ensure optimal performance and longevity:

- Wood Species: Different wood species offer varying levels of strength, durability, and aesthetic appeal. Softwoods like pine and fir are more affordable and commonly used for general construction and furniture making, while hardwoods like birch and maple offer greater hardness, durability, and a finer grain pattern, making them suitable for high-end furniture, cabinetry, and decorative applications.

- Plywood Grade: Plywood is graded based on its appearance and the quality of the veneer layers. Higher grades have fewer imperfections and a smoother surface, making them suitable for applications where appearance is critical, such as furniture making and cabinetry. Lower grades are more suitable for structural applications where appearance is less important, such as sheathing and subflooring.

- Thickness: Plywood thickness is measured in millimeters or inches and should be chosen based on the structural requirements of the application. Thicker plywood panels offer greater strength and load-bearing capacity and are typically used for structural applications like subflooring and roof sheathing. Thinner plywood panels are suitable for applications where weight and flexibility are more important, such as furniture making and cabinet doors.

- Treatments and Finishes: Plywood can be treated for moisture resistance, fire retardance, or insect resistance, and finished with various coatings to enhance its appearance and durability. Moisture-resistant plywood is essential for exterior applications and areas exposed to humidity, while fire-retardant plywood is often required for building codes in commercial and multi-family dwellings. Finishes like paint, stains, and varnishes can be applied to enhance the plywood’s appearance, protect it from moisture and UV damage, and increase its lifespan.

| Feature | Description | Considerations |

|---|---|---|

| Wood Species | The type of wood used for the veneer layers | Strength, durability, appearance, cost |

| Plywoods Grade | A rating system that reflects the quality and appearance of the plywoods | Appearance, structural integrity, cost |

| Thickness | The overall thickness of the plywood panel | Structural requirements, load-bearing capacity, weight |

| Treatments | Special treatments applied to the plywood to enhance its performance | Moisture resistance, fire retardance, insect resistance |

| Finishes | Protective and decorative coatings applied to the plywood surface | Appearance, durability, moisture protection |

FAQs: Exploring the World of Plywoods

1. What makes plywood a better choice than solid wood for certain applications?

Plywood’s cross-grained construction makes it exceptionally strong, stable, and resistant to warping, cracking, and splitting, surpassing solid wood in these aspects. This makes it ideal for applications requiring high strength, durability, and dimensional stability, like structural sheathing, subflooring, and furniture making.

2. What are the different grades of plywood, and how do I choose the right one?

Plywood grades range from A to D, with A being the highest quality with a smooth, blemish-free surface, suitable for furniture and finishing. Lower grades have more imperfections and are used for structural work where appearance is less critical. Choose the grade based on your project’s visibility and aesthetic requirements.

3. Can plywood be used for outdoor applications, or is it susceptible to moisture damage?

While standard plywood is not ideal for prolonged exposure to moisture, treated plywood options are available. Marine-grade plywood, treated with water-resistant glues and preservatives, is designed for boat building and other marine applications. Exterior-grade plywood, treated for moisture resistance, is suitable for outdoor projects like sheds and playhouses.

4. Is plywood a sustainable material choice, considering it’s made from wood?

Plywood can be a sustainable choice if sourced from responsibly managed forests. Look for certifications like Forest Stewardship Council (FSC) that ensure the wood comes from well-managed forests. Additionally, some manufacturers use recycled wood content in their plywood production, further reducing environmental impact.

5. What are some creative and unexpected uses of plywood beyond construction and furniture?

Plywood’s versatility extends to various creative applications. Its strength and ease of working make it suitable for crafting toys, musical instruments, and even jewelry. Its smooth surface is ideal for laser cutting and engraving intricate designs, making it popular for signage, art installations, and decorative elements.