In the fiercely competitive landscape of furniture design and manufacturing, every decision, from the initial sketch to the final finish, carries significant weight. Choosing the right materials, in particular, can be the defining factor that elevates a piece from ordinary to extraordinary, from fleeting trend to enduring classic. Furniture plywood, often overshadowed by its solid wood counterpart, is the unsung hero behind countless iconic and enduring furniture pieces.

This versatile material, prized for its strength, stability, and aesthetic appeal, is the secret weapon discerning designers and manufacturers rely on to create furniture that stands the test of time. Let’s delve into the world of furniture plywood and discover why it might be the missing piece in your furniture design puzzle.

What Makes Furniture Plywood Special?

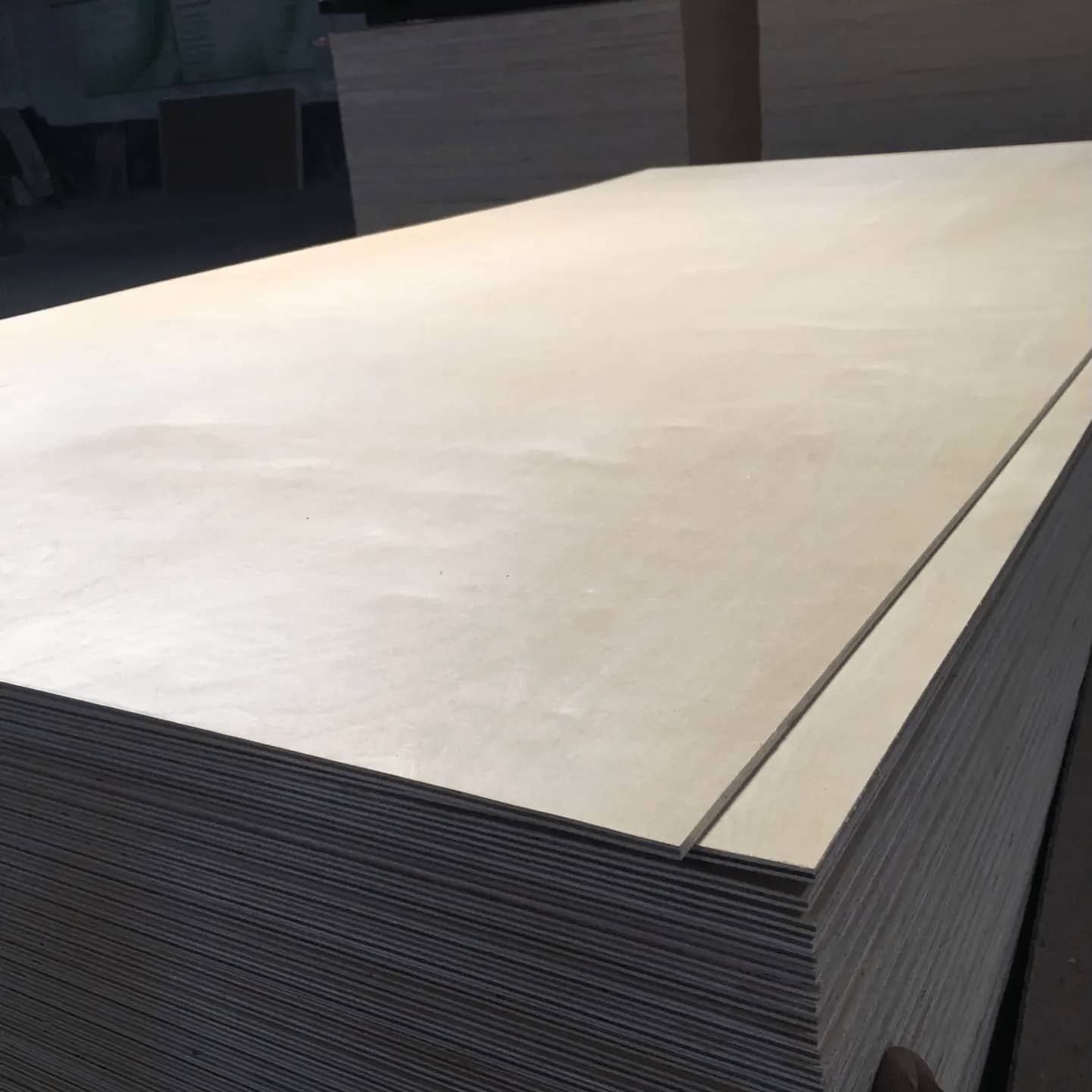

Furniture plywood is not your run-of-the-mill plywood found in construction sites. While it shares the fundamental layered construction as other types of plywood, renowned for its strength and stability, furniture plywood is meticulously crafted with a keen focus on aesthetics and workability, making it ideally suited for furniture making.

Here’s a closer look at what sets furniture plywood apart:

- High-Quality Veneer Faces: Unlike standard plywood, which may utilize lower-grade veneers on its outer layers, furniture plywood boasts high-quality hardwood veneers on its faces, showcasing the natural beauty and intricate grain patterns of the wood. These veneers are carefully selected for their visual appeal, ensuring minimal knots, blemishes, or color variations, resulting in a smooth, consistent, and visually captivating surface that elevates the aesthetic of any furniture piece.

- Smooth and Consistent Core: The core of furniture plywood, while hidden from view, is equally important in determining the panel’s overall quality and performance. It is typically constructed from high-quality softwood or hardwood veneers, carefully arranged to ensure a strong and stable substrate for the face veneers. The core is also meticulously sanded to a smooth and even finish, allowing for seamless veneering and preventing telegraphing, a common issue where the core’s texture shows through the veneer, compromising the furniture’s visual appeal.

- Variety of Hardwood Options: Furniture plywood offers a diverse palette of hardwood species to choose from, each lending its unique grain pattern, color, and characteristics to the final product. From the warm, inviting tones of cherry and mahogany, prized for their classic elegance, to the cool, contemporary appeal of maple and walnut, known for their modern sophistication, there’s a furniture plywood to harmonize with any design aesthetic and elevate the visual narrative of your furniture pieces.

Unlocking the Advantages: Why Choose Furniture Plywood?

The allure of furniture plywood extends far beyond its aesthetic appeal. This versatile material offers a compelling combination of strength, stability, workability, and sustainability, making it a smart and responsible choice for furniture designers and manufacturers.

Let’s explore the compelling reasons why furniture plywood deserves a prominent place in your furniture making repertoire:

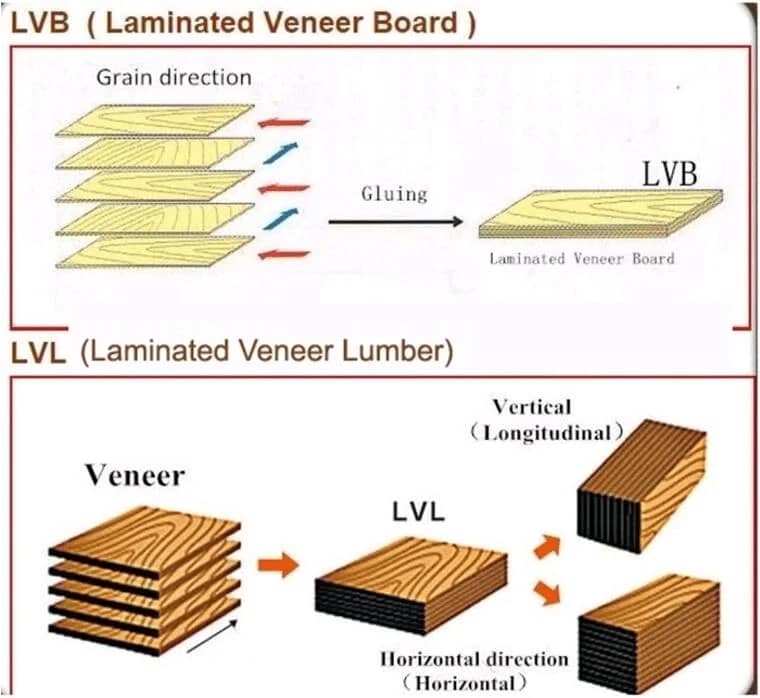

- Exceptional Strength and Stability: Furniture plywood inherits its remarkable strength and stability from its unique cross-grained construction, a hallmark of plywood engineering. This ingenious technique involves layering thin sheets of wood veneer with the grain of each layer running perpendicular to the adjacent one. This cross-graining, combined with strong adhesives and a hot-pressing process, creates a panel that exhibits exceptional strength-to-weight ratio, making it significantly stronger and more stable than solid wood of comparable thickness. This inherent strength makes furniture plywood ideal for creating durable and long-lasting furniture pieces that can withstand the rigors of daily use without warping, cracking, or sagging, ensuring that your creations remain structurally sound and visually appealing for years to come.

- Resistance to Warping and Cracking: Unlike solid wood, which can be susceptible to warping, cracking, and dimensional changes in response to fluctuations in humidity and temperature, furniture plywood demonstrates superior dimensional stability, a crucial factor in furniture making where maintaining precise shapes and dimensions is paramount. This stability stems from its cross-grained construction, where each layer’s expansion and contraction is counteracted by its adjacent layers, minimizing the overall movement of the panel. This inherent stability ensures that your furniture pieces maintain their shape and integrity over time, even in environments with varying humidity levels, preventing unsightly warping, cracks, and structural issues that can compromise the longevity and aesthetic appeal of furniture made from solid wood.

- Wide Range of Sizes and Thicknesses: Furniture plywood offers unparalleled flexibility in design and construction, thanks to its availability in a wide range of sizes and thicknesses, catering to a diverse spectrum of furniture designs and dimensions. Whether you’re crafting a delicate side table with intricate details or a robust dining table designed to accommodate large gatherings, you’ll find a furniture plywood panel that perfectly aligns with your project’s requirements. This extensive range of sizes and thicknesses allows for greater design freedom and efficient material utilization, minimizing waste and optimizing your production process.

- Cost-Effectiveness: In an industry where balancing quality and affordability is paramount, furniture plywood emerges as a cost-effective alternative to solid hardwood, especially for larger furniture pieces where the cost of solid wood can be prohibitive. This affordability, however, doesn’t come at the expense of quality. Furniture plywood delivers exceptional performance, durability, and aesthetics at a fraction of the cost of solid wood, making it an attractive option for furniture manufacturers looking to optimize their production costs without compromising on the quality and craftsmanship of their products.

- Sustainable Manufacturing Practices: As environmental consciousness continues to shape consumer preferences and industry practices, furniture plywood offers a responsible choice for environmentally conscious furniture makers. Many furniture plywood manufacturers are committed to sustainable forestry practices, sourcing their wood from responsibly managed forests that prioritize conservation, biodiversity, and the long-term health of forest ecosystems. Choosing furniture plywood from certified sustainable sources, such as those certified by the Forest Stewardship Council (FSC), allows you to create beautiful and durable furniture while minimizing your environmental impact and contributing to the preservation of our planet’s precious forest resources.

Applications Across the Furniture Spectrum

Furniture plywood’s versatility knows no bounds, making it an indispensable material for a vast array of furniture applications, spanning from classic, time-honored designs to sleek, contemporary creations. Its adaptability to diverse styles, combined with its strength, stability, and ease of working, makes it the material of choice for crafting furniture pieces that seamlessly blend form and function.

Let’s explore some of the most common and inspiring applications of furniture plywood in furniture making:

- Cabinetry and Casework: Furniture plywood stands as a cornerstone in cabinetmaking, providing a reliable and aesthetically pleasing material for constructing cabinet sides, shelves, doors, and drawer fronts. Its exceptional strength and stability ensure that cabinets can withstand the weight of stored items without sagging or warping, while its smooth, consistent surface provides an ideal foundation for applying various finishes, from rich stains to vibrant paints, allowing you to create cabinetry that seamlessly blends with any interior design scheme.

- Tables: Whether you’re crafting an elegant dining table that serves as the centerpiece of a formal dining room or a functional coffee table that anchors a cozy living space, furniture plywood offers an exceptional material for creating tabletops that are both visually captivating and exceptionally durable. Its wide range of available sizes allows you to create tabletops of any dimension, from intimate café tables to expansive banquet tables, while its smooth, consistent surface provides an ideal canvas for showcasing the natural beauty of wood grain or for applying various finishes that enhance its aesthetic appeal.

- Chairs and Seating: Furniture plywood’s remarkable strength and flexibility extend beyond flat surfaces, making it an excellent material for crafting chairs, benches, and other seating options that demand both structural integrity and ergonomic design. Its ability to be molded and shaped into curves and contours allows for creating comfortable and supportive seating that conforms to the body’s natural curves, while its smooth surface provides an excellent base for upholstery, whether it’s plush fabric, supple leather, or woven materials.

- Beds and Headboards: Furniture plywood’s inherent strength and stability make it an ideal material for constructing sturdy and reliable bed frames and headboards, ensuring that these essential furniture pieces can withstand the weight of mattresses and occupants without compromising on structural integrity or visual appeal. Its smooth, consistent surface is perfect for applying a variety of finishes, from paint and lacquer to veneer, allowing you to create bed frames and headboards that seamlessly integrate with any bedroom décor, from minimalist and modern to classic and ornate.

Making the Right Choice: Furniture Plywood Selection Guide

Navigating the world of furniture plywood requires a keen understanding of the various factors that influence its suitability for specific applications. With a plethora of options available, each catering to different needs and design visions, choosing the right furniture plywood for your project can be a daunting task.

To simplify the selection process and ensure that you’re choosing the ideal material for your furniture making endeavors, consider the following factors:

| Factor | Considerations |

|---|---|

| Wood Species | The choice of wood species for furniture plywood extends beyond aesthetics; it influences the material’s hardness, durability, grain pattern, and overall character. Each hardwood species offers a unique visual and tactile experience, from the warm, inviting tones of cherry and mahogany to the cool, contemporary appeal of maple and walnut. Consider the desired aesthetic, the furniture’s intended use, and the overall design narrative when selecting a species that harmonizes with your vision. |

| Plywood Grade | Furniture plywood is typically graded based on the quality and appearance of its face veneers, with A-grade and AA-grade being the most common for furniture applications. A-grade plywood features one good side, suitable for applications where only one side of the panel will be visible, while AA-grade plywood boasts two good sides, making it ideal for furniture pieces where both sides are on display. Choose the grade that aligns with your project’s visibility requirements and aesthetic standards. |

| Thickness | Plywood thickness plays a crucial role in determining the furniture piece’s structural integrity and ability to withstand weight and stress. Thicker plywood panels offer greater strength and load-bearing capacity, making them suitable for larger, heavier furniture pieces like dining tables and bed frames, while thinner plywood panels provide greater flexibility and are often preferred for lighter applications like cabinet doors and drawer fronts. Choose the thickness that aligns with the furniture piece’s size, intended use, and structural requirements. |

| Core Construction | The core construction of furniture plywood can significantly impact its weight, strength, screw-holding ability, moisture resistance, and formaldehyde emissions. Common core types include veneer core, particleboard core, and MDF core, each offering a different balance of properties. Consider factors like the furniture’s intended use, environmental concerns, and budget constraints when selecting a core type that meets your specific requirements. |

| Finish | The finish applied to furniture plywood not only enhances its aesthetic appeal but also provides a protective layer that shields it from moisture, scratches, and everyday wear and tear. Furniture plywood can be finished with a myriad of coatings, including paint, lacquer, varnish, and veneer, each offering a different level of durability, sheen, and visual warmth. Choose a finish that complements the wood species, enhances the furniture’s natural beauty, and provides the desired level of protection and longevity. |

Why Choose Yuantuo Plywood: Your Partner in Shipping Success

In the high-stakes world of logistics and shipping, ensuring your products arrive safely and securely is paramount. That’s where Yuantuo Plywood comes in. We’re not just another plywood supplier; we’re your dedicated partners in safeguarding your valuable cargo and optimizing your shipping operations.

Here’s why discerning businesses worldwide choose Yuantuo Plywood:

- Uncompromising Strength & Durability: We source only the highest-grade hardwood veneers and utilize state-of-the-art manufacturing processes to create packing plywood renowned for its exceptional strength and durability. Your cargo is in safe hands with Yuantuo.

- Tailored to Your Exact Needs: From heavy machinery to delicate electronics, we offer a wide range of thicknesses, wood species, and treatments to create custom packing plywood solutions tailored to your unique specifications. Odd shapes? Specific moisture resistance requirements? International shipping regulations? Consider it done.

- Sustainability at Our Core: We believe in protecting your products and our planet. That’s why we source our wood from responsibly managed forests, ensuring sustainable practices that benefit everyone. Choose Yuantuo for eco-conscious shipping solutions.

- Efficiency That Impacts Your Bottom Line: Our consistent dimensions, smooth surfaces, and ease of handling streamline your logistics, saving you valuable time and money at every step. Experience the Yuantuo difference in efficiency and cost savings.

- Partnership Beyond Plywood: We’re not just a supplier; we’re your trusted advisors. Our team of experts is here to guide you in choosing the right packing plywood solutions for your specific needs, ensuring optimal protection for your valuable cargo.

Choose Yuantuo Plywood. Choose Confidence in Every Shipment.

Contact us today, and let our experts help you optimize your shipping operations with packing plywood solutions designed to exceed your expectations.

FAQs: Navigating the World of Furniture Plywood

1. What makes furniture plywood different from other types of plywood?

Furniture plywood stands out due to its high-quality hardwood veneers on the outer layers, chosen for their smooth, visually appealing appearance. It also typically features a smoothly sanded core to prevent telegraphing, where the core’s texture shows through the veneer.

2. What are the key advantages of using furniture plywood in furniture making?

Furniture plywood offers exceptional strength and stability, resistance to warping and cracking, a wide range of sizes and thicknesses, cost-effectiveness compared to solid hardwood, and the option for sustainable sourcing.

3. What types of furniture can be made with furniture plywood?

Furniture plywood’s versatility makes it suitable for a wide range of furniture, including cabinetry, tables, chairs, beds, headboards, shelves, and more. Its strength and workability make it adaptable to various designs.

4. How do I choose the right type of furniture plywood for my project?

Consider the wood species, plywood grade (A or AA), thickness, core construction (veneer, particleboard, or MDF), and desired finish based on your project’s aesthetic, structural, and environmental requirements.

5. Is furniture plywood a sustainable material choice for furniture making?

Many manufacturers prioritize sustainable forestry practices, using wood from responsibly managed forests. Look for certifications like FSC to ensure your furniture plywood comes from sustainable sources.