In the high-stakes game of logistics and shipping, efficiency reigns supreme. Every second shaved off transit time, every inch of space maximized, and every instance of damage averted directly impacts your bottom line. Margins are razor-thin, competition is fierce, and customer expectations are soaring higher than ever. So how do you navigate this complex landscape and ensure your products arrive at their destination safely, securely, and without decimating your profits? Enter the unsung hero of the shipping industry: Packing Plywood.

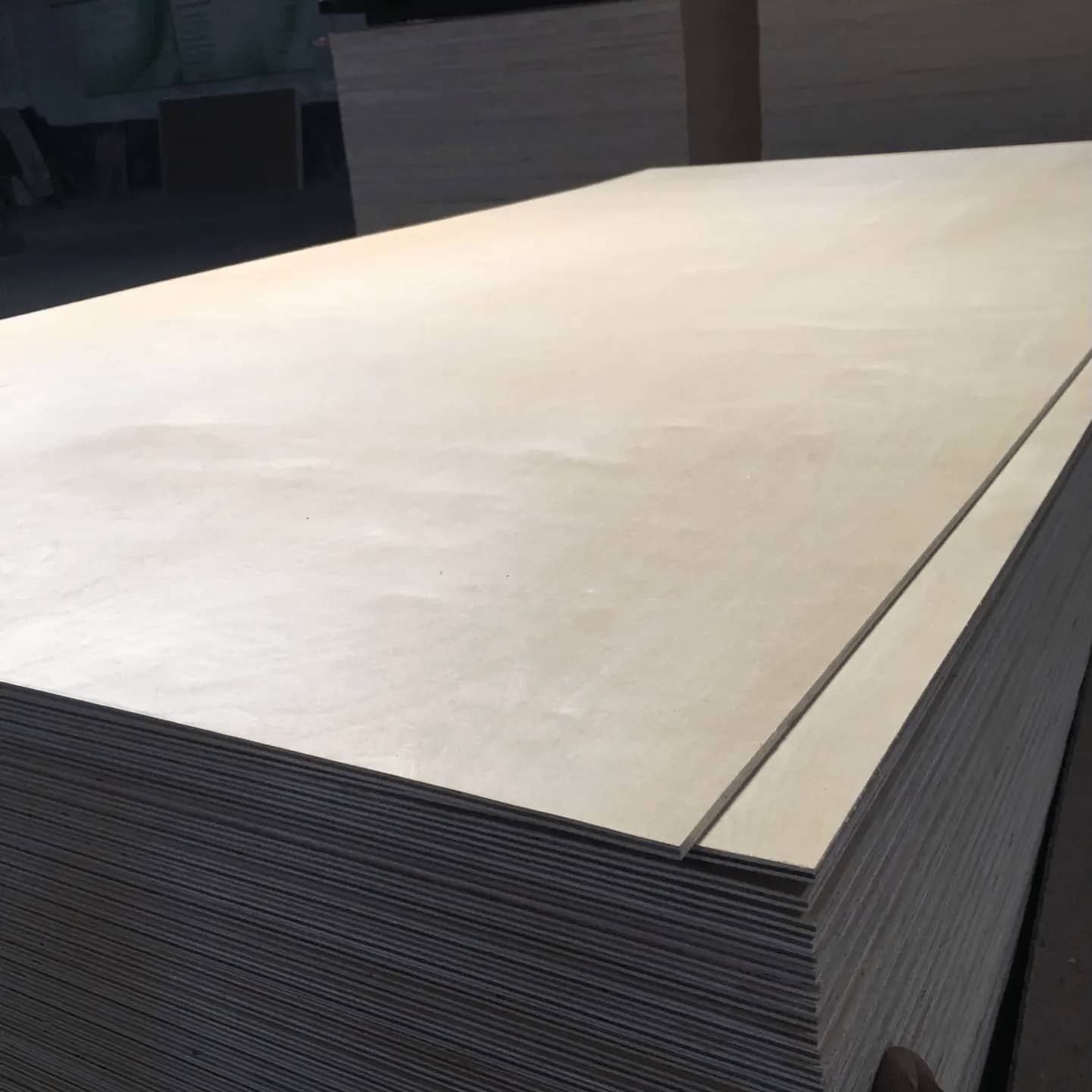

Packing plywood isn’t just another piece of lumber; it’s a purpose-built material meticulously engineered to withstand the rigors of transportation and provide unparalleled protection for your valuable cargo. It’s the silent guardian, the invisible force field, ensuring your products reach their destination in pristine condition, ready to impress your customers. Let’s delve into the world of packing plywood and discover how it can revolutionize your shipping and logistics operations.

What Makes Packing Plywood the Backbone of Efficient Shipping?

Packing plywood isn’t your run-of-the-mill plywood found at the local hardware store. It’s not intended for building bookshelves or patching up walls. This is industrial-strength protection, meticulously crafted to conquer the unpredictable world of freight and logistics. Here’s what sets it apart:

- Strength That Defies the Odds: Packing plywood is renowned for its exceptional strength and durability, capable of withstanding the bumps, jolts, and vibrations that are par for the course in transit. It’s manufactured using high-quality hardwood veneers, strategically cross-grained and bonded with incredibly strong adhesives. This creates a panel that laughs in the face of impacts, stacking pressure, and even the occasional mishandling. Your cargo remains safe and sound, minimizing the risk of damage, costly returns, and logistical nightmares.

- Moisture Resistance: Your Shield Against the Elements: Whether your shipment is braving the high seas, traversing humid jungles, or navigating unpredictable weather patterns, moisture is a constant adversary. Packing plywood, often treated with specialized water-resistant coatings or manufactured using moisture-resistant core materials, acts as an impenetrable barrier against the elements. This protective shield safeguards your goods from moisture damage, mold growth, warping, and other environmental factors that can compromise quality and value. This is particularly crucial for industries like electronics, pharmaceuticals, and food products, where even slight moisture damage can spell disaster.

- Versatility: Your One-Size-Fits-Many Solution: The beauty of packing plywood lies in its adaptability. It’s not a one-size-fits-all solution; it’s a one-size-fits-most solution. Available in a wide range of thicknesses, sizes, and grades, packing plywood can be tailored to meet the specific needs of your cargo. Whether you’re shipping heavy machinery, delicate electronics, or anything in between, there’s a packing plywood solution that’s up to the task. This adaptability makes it a cost-effective and efficient choice for businesses of all shapes and sizes.

Packing Plywood in Action: A Deep Dive into Industry Applications

Packing plywood isn’t confined to the walls of a warehouse; it’s a global citizen, traversing continents and industries, silently protecting goods and enabling businesses to thrive. Its strength, durability, and adaptability make it an indispensable asset across a multitude of sectors:

- Manufacturing & Industrial Shipping: Where Heavyweights Feel Safe

- Target Users: This is the domain of manufacturers, industrial equipment suppliers, automotive parts distributors, and anyone involved in shipping large, heavy, or complex goods.

- Applications: Packing plywood is the bedrock of secure shipping for heavy machinery, industrial equipment, automotive parts, and manufactured goods. It’s used to create robust crates, pallets, and custom packaging solutions that protect valuable assets during transportation and storage. Think massive turbines, delicate engine components, or even entire production lines – packing plywood provides the robust protection needed to ensure these high-value assets arrive safely and ready for operation.

- Advantages: Packing plywood shines in this sector due to its superior strength, impact resistance, and ability to be custom-built to accommodate large or unusually shaped items. It’s the peace of mind manufacturers and industrial giants rely on to keep their supply chains moving.

- E-commerce & Retail Logistics: Delivering Smiles, Not Shards

- Target Users: Online retailers, e-commerce platforms, fulfillment centers, and anyone shipping goods directly to consumers rely on packing plywood to ensure customer satisfaction.

- Applications: As e-commerce continues its meteoric rise, so too does the demand for reliable packaging solutions that can withstand the often-turbulent journey from warehouse to doorstep. Packing plywood provides the strength and protection needed for shipping furniture, appliances, electronics, and other fragile items, ensuring they arrive at their destination in pristine condition, ready to impress even the most discerning online shopper.

- Advantages: In the age of unboxing videos and online reviews, the last thing you want is a customer unpacking a damaged product. Packing plywood’s ability to withstand the rigors of last-mile delivery, where packages are often handled multiple times and subjected to various environmental conditions, makes it a top choice for e-commerce businesses.

- Construction & Building Materials: Building Success, One Shipment at a Time

- Target Users: Construction companies, building material suppliers, contractors, and anyone involved in the intricate dance of building construction rely on packing plywood to keep their projects on track.

- Applications: Packing plywood is instrumental in safely transporting construction materials, such as windows, doors, countertops, and delicate fixtures. Its ability to withstand impacts and moisture makes it ideal for protecting these valuable building components during transit and on-site storage. Construction sites are notoriously demanding environments, and packing plywood ensures these materials arrive undamaged and ready for installation.

- Advantages: Time is money in construction, and delays due to damaged materials can be costly. Packing plywood’s resistance to moisture, impact, and its ability to be easily labeled and inventoried on-site make it essential for keeping construction projects on schedule and within budget.

- Art & Antiques Shipping: Preserving Legacy, One Crate at a Time

- Target Users: Art galleries, museums, auction houses, antique dealers, and private collectors entrust their most prized possessions to the protective embrace of packing plywood.

- Applications: When it comes to protecting priceless and irreplaceable items, packing plywood offers unparalleled peace of mind. It’s used to create custom crates and specialized packaging for art pieces, antiques, and other delicate valuables, ensuring their safe transport to galleries, museums, and private collectors.

- Advantages: Packing plywood’s ability to be custom-built to cradle delicate items, its cushioning properties, and its suitability for climate-controlled shipping make it the gold standard for protecting these high-value, often irreplaceable objects. It’s the silent guardian of history, preserving our cultural heritage for generations to come.

The Bottom-Line Benefits: Why Packing Plywood is a Smart Investment

Investing in high-quality packing plywood isn’t just about ticking a box on your shipping checklist; it’s a strategic decision that reverberates throughout your entire operation, positively impacting your bottom line in tangible ways:

- Reduced Shipping Costs: Preventing Damage Before it Costs You Packing plywood’s strength and durability translate to fewer instances of damage during transit, minimizing costly repairs, replacements, and insurance claims. Think of it as an insurance policy for your shipments, absorbing the shocks and impacts that can lead to financial headaches. Its lightweight nature can also contribute to lower shipping weights, further reducing transportation expenses. In an industry where every penny counts, these savings can make a significant difference to your bottom line.

- Enhanced Customer Satisfaction: Delivering Delight, Not Disappointment Damaged goods lead to unhappy customers, returns, and potential damage to your brand reputation. In today’s hyper-connected world, negative reviews can spread like wildfire, impacting your brand image and future sales. Packing plywood ensures your products arrive in pristine condition, fostering customer satisfaction, loyalty, and positive reviews. Happy customers are repeat customers, and packing plywood plays a key role in ensuring those positive experiences.

- Streamlined Logistics & Handling: Efficiency in Every Step Packing plywood’s consistent dimensions and ease of handling contribute to more efficient loading, unloading, and warehousing operations. Its smooth, flat surface is ideal for labeling, barcoding, and inventory management, reducing errors and streamlining your logistics processes. Its compatibility with various fastening methods simplifies packaging processes, saving time and labor costs. In a fast-paced logistics environment, these time savings translate to increased efficiency and cost reductions.

- Sustainable Choice for Eco-Conscious Businesses: Shipping with a Conscience Many packing plywood manufacturers are committed to sustainable forestry practices, utilizing wood sourced from responsibly managed forests. Choosing sustainable packing plywood aligns your business with eco-conscious values and reduces your environmental footprint. As consumers become increasingly environmentally conscious, choosing sustainable packaging options can enhance your brand image and resonate with eco-minded customers.

Choosing the Right Packing Plywood: Factors to Consider

Selecting the appropriate packing plywood requires careful consideration of your specific needs and the demands of your shipping operations. It’s not a one-size-fits-all solution, and understanding the nuances of different types of packing plywood can help you optimize your packaging and maximize your investment. Here’s a breakdown of key factors to keep in mind:

- Plywood Thickness: Matching Strength to Need Thicker plywood offers greater strength and impact resistance, making it suitable for heavier or more fragile cargo. Thinner options may suffice for lighter items or internal bracing within packaging. Consider the weight and fragility of your cargo, as well as the anticipated stresses during transit, when determining the appropriate thickness.

- Wood Species & Grade: Finding the Right Balance of Strength and Cost Different wood species possess varying strengths, durability, and moisture resistance. Consider the specific requirements of your cargo and shipping environment when selecting the wood species and grade of your packing plywood. For example, hardwoods like Oak or Birch offer exceptional strength and durability, while softwoods like Pine or Fir are more lightweight and cost-effective.

- Surface Treatments & Coatings: Adding Layers of Protection Packing plywood can be treated with various coatings to enhance its moisture resistance, insect repellency, or fire retardancy. Choose treatments that align with the specific needs of your cargo and shipping regulations. For example, if you’re shipping internationally, you may need to comply with ISPM-15 regulations, which require wood packaging materials to be treated to prevent the spread of pests.

| Feature | Description | Considerations |

|---|---|---|

| Thickness | Ranges from 1/4 inch to over 1 inch | Heavier cargo and longer shipping distances generally require thicker plywood. Consider the weight, fragility, and stacking height of your cargo. |

| Wood Species | Common options include Pine, Spruce, Fir, and Hardwood varieties | Consider the strength, weight, and moisture resistance properties of each species. Hardwoods offer greater strength but are heavier and more expensive. Softwoods are lighter and more cost-effective but may not be suitable for heavy-duty applications. |

| Grade | Reflects the quality and appearance of the plywood surface | Choose higher grades for applications where aesthetics are important, such as packaging for consumer goods. Lower grades are suitable for purely functional purposes, such as industrial crates. |

| Treatments | Water-resistant coatings, fire retardants, insect repellents | Select treatments based on the specific needs of your cargo and shipping regulations. Moisture-resistant coatings are essential for protecting goods from humidity and condensation. Fire retardants may be required for certain types of cargo or shipping methods. Insect repellents are crucial for international shipping to comply with ISPM-15 regulations. |

Why Choose Yuantuo Wood Packing Plywood? Your Partner in Shipping Success

You’ve just explored the ins and outs of packing plywood and its undeniable impact on your bottom line. Now, it’s time to choose a partner who understands the intricacies of your industry and delivers packing plywood solutions engineered for your success.

Yuantuo Wood isn’t just another plywood supplier; we’re your dedicated allies in navigating the complex world of shipping and logistics. Here’s why discerning businesses choose Yuantuo Wood:

- Uncompromising Strength & Durability: We source only the highest-grade hardwood veneers and utilize state-of-the-art manufacturing processes to create packing plywood that can withstand the most demanding shipping conditions. Your cargo is safe with us.

- Tailored to Your Needs: Odd shapes? Specific moisture resistance requirements? International shipping regulations? We offer a wide range of thicknesses, wood species, and treatments to create custom packing plywood solutions tailored to your exact specifications.

- Sustainability at Our Core: We believe in protecting your products and our planet. That’s why we source our wood from responsibly managed forests, ensuring sustainable practices that benefit everyone.

- Efficiency That Impacts Your Bottom Line: Our consistent dimensions, smooth surfaces, and ease of handling streamline your logistics, saving you time and money at every step.

- Partnership Beyond Plywood: We’re not just a supplier; we’re your trusted advisors. Our team of experts is here to guide you in choosing the right packing plywood solutions for your specific needs, ensuring optimal protection for your valuable cargo.

Choose Yuantuo Wood. Choose Confidence in Every Shipment.

Contact us today for a consultation and let us help you optimize your shipping operations with packing plywood solutions that deliver results.

Packing Plywood FAQs: Your Questions Answered

1. What’s the difference between packing plywood and regular plywood? Can’t I just use what I have in the stockroom?

While they might look similar at a glance, packing plywood is in a different league than standard plywood. It’s specifically engineered to withstand the rigors of shipping. Think of it like this: you wouldn’t wear your running shoes to a construction site.

Here’s the breakdown:

- Strength: Packing plywood uses higher-grade veneers and stronger adhesives, making it significantly more resistant to impacts, vibrations, and stacking pressure. Regular plywood is more prone to breakage or warping under these conditions.

- Moisture Resistance: Packing plywood often has specialized coatings or uses moisture-resistant core materials to protect your goods from humidity, spills, and the elements. Regular plywood lacks this level of protection.

- Treatments: Packing plywood can be treated for insect resistance (crucial for international shipping) and fire retardancy, meeting specific regulations that regular plywood might not.

Using the wrong type of plywood is a recipe for damaged goods, unhappy customers, and ultimately, higher costs for your business.

2. My products are oddly shaped. Can packing plywood accommodate that?

Absolutely! That’s one of the greatest advantages of packing plywood. It can be easily cut, shaped, and customized to create crates and packaging solutions for even the most awkwardly sized products. This ensures a snug and secure fit, minimizing movement during transit and reducing the risk of damage.

3. I’m concerned about sustainability. Is packing plywood an environmentally friendly option?

Many manufacturers are committed to sustainable forestry practices. Look for packing plywood sourced from responsibly managed forests – you’ll often find certifications like FSC (Forest Stewardship Council) that indicate responsible sourcing. By choosing sustainable packing plywood, you’re not only protecting your products but also contributing to the health of our planet.

4. How do I choose the right thickness of packing plywood for my needs?

This depends on several factors:

- Weight of your cargo: Heavier items need thicker plywood for adequate support and protection.

- Fragility: Delicate items benefit from thicker plywood to absorb shocks and vibrations.

- Shipping distance and mode: Longer journeys, especially via sea freight, often require more robust packaging with thicker plywood.

It’s always best to consult with packaging experts or your shipping provider to determine the optimal thickness for your specific needs.

5. Packing plywood seems like an added expense. Is it really worth the investment?

Consider this: the cost of packing plywood is a small price to pay compared to the potential costs of damaged goods, customer returns, shipping delays, and damage to your brand reputation. Packing plywood is an investment in:

- Reduced risk: It significantly minimizes the likelihood of damage during transit, saving you money on replacements, repairs, and insurance claims.

- Increased efficiency: Its consistent dimensions and ease of handling streamline logistics, saving you time and labor costs.

- Enhanced customer satisfaction: Products arrive in pristine condition, leading to happier customers and positive reviews, which are invaluable for your business.

In the grand scheme of your shipping operations, packing plywood is a small investment that yields significant returns in the form of cost savings, efficiency gains, and a stronger brand reputation.