The world of construction thrives on the versatility and resilience of concrete. From towering skyscrapers that kiss the clouds to intricate networks of bridges connecting communities, concrete is the backbone of our built environment. But behind every smooth, perfectly formed concrete structure stands a silent hero: formwork plywood. This often-overlooked champion of construction sites ensures precision, durability, and efficiency in concrete construction.

Choosing the right formwork plywood supplier is not merely a procurement task; it’s about forging a strategic partnership that can significantly impact the success of your projects. It’s about aligning with experts who understand your needs, prioritize quality, and provide unwavering support throughout your construction journey.

This comprehensive guide delves deep into the world of formwork plywood suppliers, equipping you with the knowledge and insights to make informed decisions that elevate your concrete construction endeavors.

Why Choosing the Right Formwork Plywood Supplier Matters: A Foundation for Success

Imagine this: you’re in the midst of a large-scale construction project, the clock is ticking, and the quality of your concrete work is under scrutiny. Suddenly, you’re grappling with warped plywood panels, frustrating delamination issues, or inconsistent panel sizes that throw your entire project off balance. These aren’t minor inconveniences; they’re costly setbacks that can jeopardize deadlines, compromise structural integrity, and tarnish your reputation.

Partnering with a reputable and experienced formwork plywood supplier transcends a simple transaction; it’s about securing a partnership built on trust, expertise, and a shared commitment to excellence. Here’s why this decision is paramount:

- Superior Product Quality: The Cornerstone of Excellence: High-quality formwork plywood is the bedrock upon which smooth, flawless concrete surfaces are built. Reputable suppliers understand that quality is non-negotiable. They invest in premium hardwood veneers, employ rigorous manufacturing processes, and implement stringent quality control measures to ensure their plywood consistently meets the highest industry standards. This translates to concrete structures that are not only visually appealing but also structurally sound and built to withstand the test of time.

- Consistent Supply and Timely Delivery: Keeping Your Projects on Track: The construction industry operates on tight schedules and demanding deadlines. Delays in material delivery can have a ripple effect, impacting subsequent tasks, escalating labor costs, and potentially jeopardizing project completion dates. A reliable formwork plywood supplier understands the criticality of timely delivery. They have robust inventory management systems, efficient logistics networks, and a proactive approach to communication, ensuring your plywood arrives exactly when and where you need it, keeping your projects moving seamlessly.

- Technical Expertise and Support: Guiding You Towards Optimal Solutions: Choosing the right formwork plywood for your specific project can be complex. Factors like concrete pressure, design complexity, and desired finish all influence the ideal plywood type, thickness, and overlay. The best formwork plywood suppliers don’t just sell you a product; they offer invaluable technical expertise. They take the time to understand your project requirements, provide expert guidance on plywood selection, and offer tailored solutions that optimize performance and cost-effectiveness.

- Competitive Pricing and Value-Added Services: Maximizing Your Investment: While price is always a factor in construction projects, it should never overshadow the importance of quality, reliability, and service. Look for suppliers who offer competitive pricing without compromising on product excellence. Furthermore, seek out those who go the extra mile by providing value-added services such as custom cutting to your specifications, flexible delivery scheduling to accommodate your project’s rhythm, and readily available on-site support to address any challenges that may arise.

Key Factors to Consider When Selecting a Formwork Plywood Supplier: Your Due Diligence Checklist

Navigating the vast landscape of formwork plywood suppliers requires a discerning eye and a strategic approach. It’s not a decision to be taken lightly. Thorough research and careful consideration of key factors are essential to ensure you’re partnering with a supplier who aligns with your project goals and values.

Here’s a comprehensive checklist to guide your evaluation process:

1. Industry Experience and Reputation: A Legacy of Excellence:

- Longevity and Track Record: How long has the supplier been operating in the formwork plywood industry? A long-standing presence often indicates stability, experience, and a proven ability to adapt to market demands. What is their track record of delivering high-quality products and services consistently? Look for suppliers with a history of exceeding customer expectations and a portfolio of successful projects.

- Industry Standing and Recognition: What is their reputation within the construction industry? Are they known for their integrity, reliability, and commitment to customer satisfaction? Seek out suppliers who are well-regarded by industry peers and have a reputation for upholding ethical business practices.

- Client Feedback and Testimonials: Are there online reviews, client testimonials, or case studies available that provide insights into their performance and customer experiences? Independent feedback from previous clients can offer valuable perspectives on the supplier’s strengths, weaknesses, and overall approach to customer relationships.

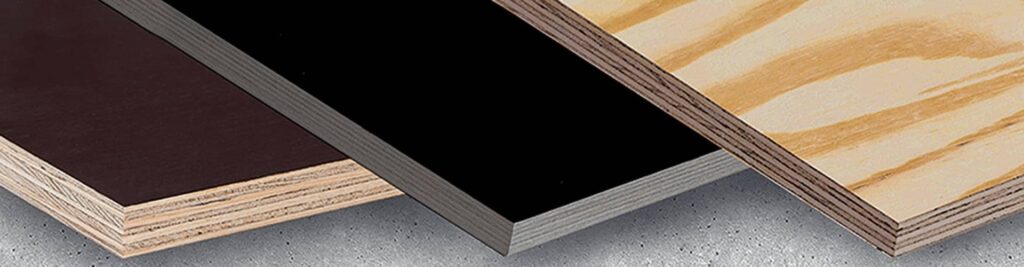

2. Product Range and Quality: Meeting Diverse Needs with Uncompromising Standards:

- Comprehensive Product Portfolio: Do they offer a wide range of formwork plywood types, sizes, and overlays to cater to diverse project needs and design complexities? A comprehensive product portfolio ensures you can source all your formwork plywood requirements from a single supplier, streamlining logistics and potentially securing volume discounts.

- Premium Materials and Manufacturing: What types of hardwood veneers do they use in their plywood production? Hardwoods like Birch, Poplar, and Eucalyptus are known for their strength, durability, and smooth surfaces, making them ideal for formwork applications. How do they ensure the quality of their veneers and adhesives? Look for suppliers who prioritize sourcing from sustainably managed forests and employ rigorous quality control measures throughout the manufacturing process.

- Specialized Plywood Solutions: Do they offer specialized plywood options like oversized panels for large-scale infrastructure projects, flexible plywood for creating curved concrete elements, or textured plywood for achieving unique architectural finishes? The availability of specialized plywood solutions demonstrates the supplier’s commitment to innovation, their understanding of diverse project needs, and their ability to provide tailored solutions.

- Moisture Resistance and Durability Enhancements: What type of resin impregnation and edge sealing processes do they use to enhance moisture resistance and prolong the lifespan of their plywood? Effective resin impregnation and edge sealing are crucial for preventing water damage, swelling, and delamination, ensuring your formwork plywood can withstand multiple uses and deliver a long service life.

3. Production Capabilities and Capacity: Ensuring Timely Delivery and Consistent Quality:

- Manufacturing Capacity and Scalability: Do they have the manufacturing capacity to handle your project volume and meet your required timelines without compromising on quality or delivery schedules? Inquire about their production capacity, lead times, and ability to scale production up or down based on project demands.

- Technological Advancements and Efficiency: Are their production facilities equipped with advanced technology and automated processes to ensure consistent product quality, minimize waste, and optimize production efficiency? Modern manufacturing techniques can significantly impact the precision, consistency, and overall quality of formwork plywood.

- Supply Chain Management and Resilience: Do they have a robust and reliable supply chain for raw materials and essential components? A well-managed supply chain mitigates the risk of material shortages, production delays, and price fluctuations, ensuring your project stays on track and within budget.

4. Sustainability Practices: Building a Greener Future:

- Responsible Forestry and Sourcing: Do they source their wood from sustainably managed forests that adhere to responsible forestry practices? Sustainable forestry ensures the long-term health of forests, protects biodiversity, and combats deforestation. Look for suppliers who prioritize sourcing from certified sustainable forests.

- Environmental Certifications and Compliance: Do they hold relevant certifications, such as those from the Forest Stewardship Council (FSC) or the Programme for the Endorsement of Forest Certification (PEFC)? These certifications provide independent verification of their commitment to responsible forestry practices and sustainable sourcing.

- Low-Emission Products and Manufacturing: Do their products meet or exceed low formaldehyde emission standards, such as those set by the California Air Resources Board (CARB) or the U.S. Environmental Protection Agency (EPA)? Formaldehyde is a volatile organic compound (VOC) that can be harmful to human health. Choosing low-emission plywood contributes to healthier indoor air quality and a more sustainable built environment.

5. Customer Service and Support: Building Lasting Partnerships:

- Responsiveness and Communication: Are they responsive to inquiries, provide timely quotes, and maintain clear and consistent communication throughout the ordering and delivery process? Effective communication is crucial for building trust, managing expectations, and ensuring a smooth and hassle-free experience.

- Technical Expertise and Problem-Solving: Do they have a knowledgeable and experienced team who can provide technical support, answer your questions, and offer guidance on selecting the right plywood for your specific project requirements? Access to technical expertise can prove invaluable when facing complex design challenges or needing advice on optimizing plywood performance.

- Value-Added Services and Solutions: Do they offer value-added services such as custom cutting to your specifications, flexible delivery scheduling to accommodate your project’s rhythm, readily available on-site support to address any challenges that may arise, or assistance with plywood installation techniques? Value-added services can save you time, reduce waste, and enhance the overall efficiency of your projects.

Making the Right Choice: A Comparative Approach to Supplier Evaluation

When faced with multiple potential formwork plywood suppliers, it’s essential to have a structured approach to evaluate and compare their offerings objectively. Creating a comparative analysis table allows you to weigh different factors side-by-side and make a well-informed decision that aligns with your project’s specific needs and priorities.

Here’s a sample table to guide your assessment:

| Supplier | Experience & Reputation | Product Range & Quality | Production Capabilities | Sustainability Practices | Customer Service & Support | Overall Rating |

|---|---|---|---|---|---|---|

| Supplier A | 8/10 | 7/10 | 9/10 | 6/10 | 8/10 | 7.6/10 |

| Supplier B | 9/10 | 8/10 | 7/10 | 9/10 | 7/10 | 8/10 |

| Supplier C | 7/10 | 9/10 | 8/10 | 8/10 | 9/10 | 8.2/10 |

FAQs: Diving Deeper into Formwork Plywood Supplier Selection

1. My project has a tight budget, but I also want to ensure the plywood’s longevity. How do I balance cost-effectiveness with quality and durability?

It’s tempting to prioritize the lowest price, but remember that formwork plywood is an investment. Higher-quality plywood, while potentially having a higher upfront cost, often offers a longer lifespan, meaning fewer replacements and potentially lower overall project costs in the long run. Discuss your budget constraints openly with potential suppliers; they may be able to recommend plywood options or grades that offer the best balance of quality and affordability for your specific needs.

2. I’m seeing terms like “WBP” and “MR” when it comes to plywood. What do these mean, and how do they relate to my project’s requirements?

These acronyms refer to the glue used in the plywood and its moisture resistance. “WBP” stands for “Water Boil Proof” and indicates a highly water-resistant glue, making it suitable for exterior applications or projects with high moisture exposure. “MR” stands for “Moisture Resistant” and offers moderate water resistance, making it suitable for many interior applications or projects with controlled humidity. Understanding these classifications helps you choose plywood with the appropriate moisture resistance for your project’s environment and ensures optimal performance and longevity.

3. My project involves complex concrete shapes and designs. How can I be sure the supplier can handle these intricate specifications?

Before committing to a supplier, it’s wise to discuss your project’s specific design complexities. Inquire about their experience with similar projects, their ability to handle custom formwork shapes, and whether they offer technical assistance in optimizing plywood use for intricate designs. Some suppliers may have in-house engineering teams or work closely with formwork design specialists who can provide valuable insights and support for challenging projects.

4. Sustainability is a core value for our company. Beyond sourcing, what sustainable practices should I look for in a formwork plywood supplier?

A truly sustainable supplier goes beyond responsible sourcing. Inquire about their manufacturing processes – do they utilize energy-efficient equipment, minimize waste through recycling programs, or utilize renewable energy sources in their facilities? A supplier’s commitment to environmental responsibility throughout their operations demonstrates a genuine dedication to sustainability.

5. We’re a smaller construction firm, and this is our first time using formwork plywood on this scale. What kind of support can we expect from a reputable supplier?

Reputable suppliers value all clients, regardless of project size. Don’t hesitate to communicate your needs and concerns openly. A good supplier will guide you through the plywood selection process, offer technical advice on installation and handling, and be readily available to address any questions or challenges that arise during your project. They should be viewed as a partner invested in your success.

Why Choose Yuantuo Wood for Your Formwork Plywood Needs?

At Yuantuo Wood, we understand that your construction projects demand more than just materials; they require a partner committed to quality, reliability, and sustainability. Our approach to formwork plywood supply directly addresses the key factors you’ve read about in this guide:

- Unwavering Commitment to Quality: We believe that superior concrete structures begin with exceptional formwork. That’s why we source only the finest hardwood veneers and employ rigorous manufacturing processes to produce formwork plywood that consistently exceeds industry standards. Our plywood is renowned for its exceptional strength, durability, and ability to deliver smooth, flawless concrete finishes.

- Reliable Supply and Timely Delivery: We recognize that time is of the essence in construction. Our robust inventory management system and efficient logistics network ensure that your formwork plywood arrives on time and in pristine condition, keeping your projects on schedule and within budget.

- Technical Expertise and Collaborative Support: Our team of experienced professionals is dedicated to providing you with expert guidance and tailored solutions. We take the time to understand your project requirements, offering technical advice on plywood selection, optimization strategies, and best practices to achieve your desired outcomes.

- Sustainability as a Core Value: We share your commitment to responsible forestry and environmental stewardship. Our sourcing practices prioritize suppliers who adhere to strict sustainability standards, ensuring that our formwork plywood contributes to a healthier planet. We are proud to offer FSC-certified plywood, providing you with the assurance that your materials come from responsibly managed forests.

- Building Lasting Partnerships: At Yuantuo Wood, we believe in building long-term relationships with our clients based on trust, transparency, and mutual success. Our commitment to exceptional customer service, ongoing support, and exceeding your expectations makes us the ideal partner for your formwork plywood needs.