In the competitive world of furniture, especially when it comes to something as personal as a good night’s sleep, every detail matters. While mattresses often steal the spotlight, savvy manufacturers and retailers know that what lies beneath can make or break the comfort, durability, and overall appeal of a bed. That’s where custom bed slats come in, offering a powerful combination of functionality, customization, and brand differentiation.

Why Bed Slats Matter More Than You Think

Let’s face it, bed slats aren’t exactly the first thing that springs to mind when you picture a luxurious sleep experience. But here’s the truth: they play a pivotal role in creating a supportive, comfortable, and long-lasting foundation for a good night’s rest.

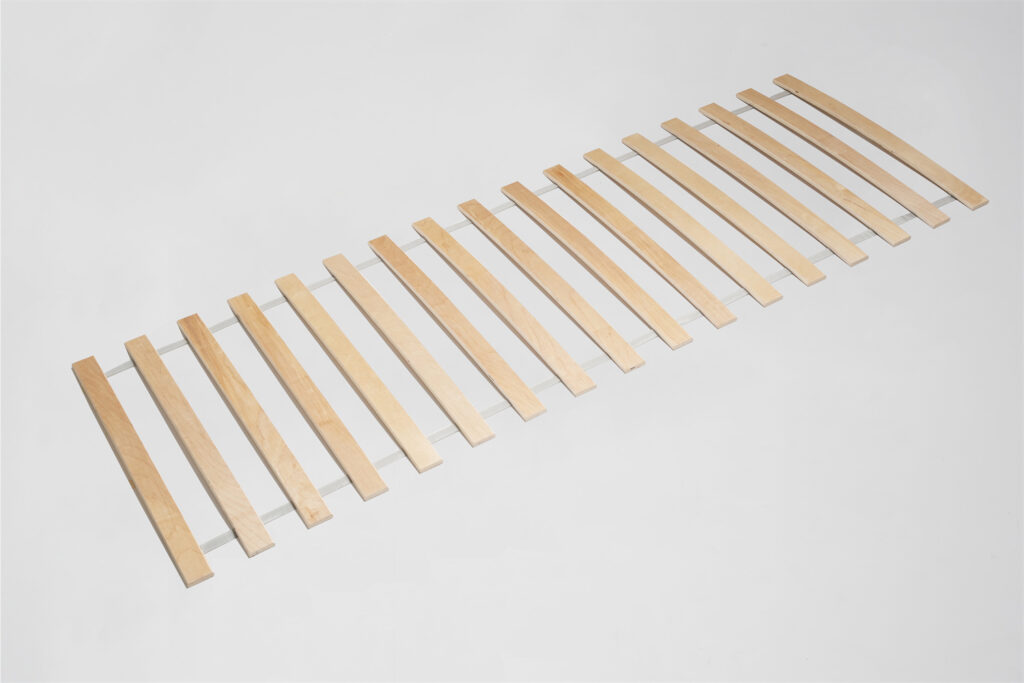

- Support and Comfort: Bed slats act as the unsung heroes of support, forming a crucial link between the mattress and the bed frame. They distribute weight evenly across the bed base, preventing sagging and creating a more comfortable and ergonomic sleep surface for your customers. This is particularly important for heavier individuals or couples, ensuring consistent support and minimizing pressure points.

- Durability and Longevity: A well-designed slat system significantly enhances the lifespan of the mattress. By promoting airflow beneath the mattress, slats help to dissipate heat and moisture, preventing the buildup of mold, mildew, and allergens. This is essential for maintaining a hygienic sleep environment and ensuring the mattress remains fresh and comfortable for years to come.

- Customization and Adjustability: Unlike one-size-fits-all bed springs, custom bed slats offer a level of personalization that sets your brand apart. They can be tailored to specific mattress types, bed frame designs, and even individual sleep preferences, allowing you to cater to a wider range of customer needs and create truly customized sleep solutions.

The Power of Custom: Why Settle for Generic When You Can Have Exceptional?

In a sea of mass-produced bed frames, offering custom bed slats is a strategic move that resonates with both retailers and end consumers. It’s a testament to your commitment to quality, craftsmanship, and providing a truly tailored sleep experience.

- Meet Diverse Needs: The beauty of customization lies in its ability to cater to a wide spectrum of requirements. Offer slats in various materials, sizes, and configurations to accommodate different bed sizes (twin, full, queen, king, California king), mattress types (memory foam, latex, innerspring, hybrid), and weight capacities. This allows you to target specific customer segments and provide solutions for even the most unique sleep needs.

- Enhance Brand Value: In a market saturated with generic options, customization is a powerful differentiator. By offering bespoke bed slat solutions, you position your brand as attentive to detail, dedicated to quality, and invested in providing a superior sleep experience. This resonates with discerning customers who are willing to pay a premium for personalized comfort and craftsmanship.

- Streamline Inventory: Partnering with a specialized manufacturer allows you to streamline your inventory management and reduce storage costs. Instead of stocking a vast inventory of pre-made slats, you can order on-demand, tailored to your specific requirements. This minimizes waste, reduces overhead, and allows you to be more agile in responding to market demands.

Unpacking the Possibilities: Exploring Custom Bed Slat Options

The beauty of customization lies in its flexibility. Here’s a deeper dive into the world of custom bed slat options:

1. Material Matters:

- Solid Wood: A timeless choice for bed slats, solid wood offers a classic aesthetic and enduring durability. Options range from budget-friendly pine and fir to premium hardwoods like oak, maple, cherry, and walnut. Each wood species boasts unique characteristics in terms of grain pattern, color, and strength, allowing you to match the slats to the desired aesthetic and price point of your bed frames.

- Plywood: A cost-effective and surprisingly sturdy option, plywood is made by layering thin sheets of wood veneer together with adhesive. It offers consistent strength and stability, and is often available with moisture-resistant treatments for enhanced durability. Plywood slats are an excellent choice for high-volume production runs where cost-efficiency is key.

- Metal: Known for its sleek, modern aesthetic and exceptional strength, metal is an increasingly popular choice for bed slats, especially in contemporary bed designs. Steel slats are particularly robust and can support heavier mattresses with ease. They are also resistant to moisture, insects, and temperature fluctuations, making them a durable and low-maintenance option.

2. Size and Spacing:

- Width and Thickness: Slat dimensions play a crucial role in determining the overall strength and support of the bed base. Wider and thicker slats offer greater weight capacity and are ideal for heavier mattresses or individuals. The thickness of the slats also influences flexibility – thinner slats provide a slightly more responsive feel, while thicker slats offer a firmer, more rigid support.

- Slat Spacing: The distance between slats is another critical factor to consider. Closer slat spacing provides more even support for the mattress and is generally recommended for foam mattresses, which require a more solid foundation. Wider slat spacing can be used with innerspring mattresses, which have built-in support structures.

3. Added Features:

- Center Support Rails: For larger beds (queen, king, California king), incorporating center support rails is essential to prevent sagging and ensure even weight distribution. These rails run down the middle of the bed frame, providing additional support for the slats and enhancing the overall structural integrity of the bed base.

- Adjustable Slats: Elevate your offerings with adjustable slats that allow customers to fine-tune the firmness level of their bed. These slats feature adjustable caps or mechanisms that allow users to increase or decrease slat tension in specific zones, providing customized support for different body types and sleep preferences.

- Pre-Drilling for Hardware: Streamline assembly processes and ensure secure attachment to bed frames by opting for pre-drilled slats. This eliminates the need for customers or assemblers to drill holes on-site, saving time, reducing the risk of errors, and ensuring a hassle-free assembly experience.

The Business Benefits: Why Custom Bed Slats Make Sense

Beyond the obvious advantages for your customers, partnering with a custom bed slat manufacturer offers compelling benefits for your business, enhancing your operations, boosting customer satisfaction, and ultimately, strengthening your brand.

- Reduced Costs: Custom manufacturing doesn’t have to mean exorbitant prices. By working directly with a specialized manufacturer, you can often achieve cost savings compared to sourcing pre-made components. Streamlined manufacturing processes, optimized material usage, and the ability to order on-demand contribute to a more cost-effective production cycle.

- Enhanced Efficiency: Tailored solutions are inherently more efficient. By ordering slats in the exact sizes, materials, and configurations you need, you minimize waste, reduce storage requirements, and simplify your inventory management. This streamlined approach frees up valuable time and resources that can be redirected towards other areas of your business.

- Increased Customer Satisfaction: In today’s competitive market, customer satisfaction is paramount. Offering customizable options demonstrates your commitment to meeting individual needs and providing a superior experience. Happy customers are more likely to become repeat buyers, recommend your brand to others, and contribute to positive online reviews, all of which are invaluable for long-term success.

- Competitive Advantage: In a sea of mass-produced furniture, customization is a powerful differentiator. By offering bespoke bed slat solutions, you set your brand apart from the competition, attracting discerning customers who value quality, craftsmanship, and personalized comfort. This unique selling proposition can give you a significant edge in a crowded market.

Choosing the Right Partner: Key Considerations

Selecting the right custom bed slat manufacturer is crucial for a successful partnership. Thorough research and careful consideration are essential to ensure you align with a partner who understands your needs, shares your commitment to quality, and can deliver on their promises.

| Factor | Description |

|---|---|

| Experience | Look for a manufacturer with a proven track record in producing high-quality bed slats. Inquire about their years in business, their client portfolio, and their experience working with companies of your size and scope. |

| Capabilities | Ensure they have the equipment, technology, and expertise to handle your desired materials, sizes, and customization options. Don’t hesitate to ask for samples of their work and inquire about their production capacity to ensure they can meet your volume requirements. |

| Quality | Quality should be non-negotiable. Inquire about their quality control processes, certifications (such as ISO 9001), and the origin of their materials. A reputable manufacturer will be transparent about their sourcing practices and committed to using high-grade materials that meet industry standards. |

| Lead Times | Discuss production lead times and delivery schedules to ensure they align with your business needs. Timely delivery is crucial for maintaining smooth operations and meeting customer expectations. Inquire about their capacity to handle rush orders if needed. |

| Communication | Choose a partner who is responsive, communicative, and genuinely committed to understanding your specific requirements. Clear and open communication is essential for a successful partnership. Look for a manufacturer who is readily available to answer your questions, address your concerns, and provide updates throughout the production process. |

Beyond the Slats: Adding Value with Accessories and Services

Many custom bed slat manufacturers offer additional services and accessories that can further enhance your offerings, streamline your operations, and provide a more comprehensive solution for your business.

- Hardware Kits: Simplify the assembly process for your customers by offering pre-packaged hardware kits that include all the necessary screws, bolts, connectors, and tools required to assemble the bed slats. This eliminates guesswork for customers and ensures a smooth and hassle-free assembly experience.

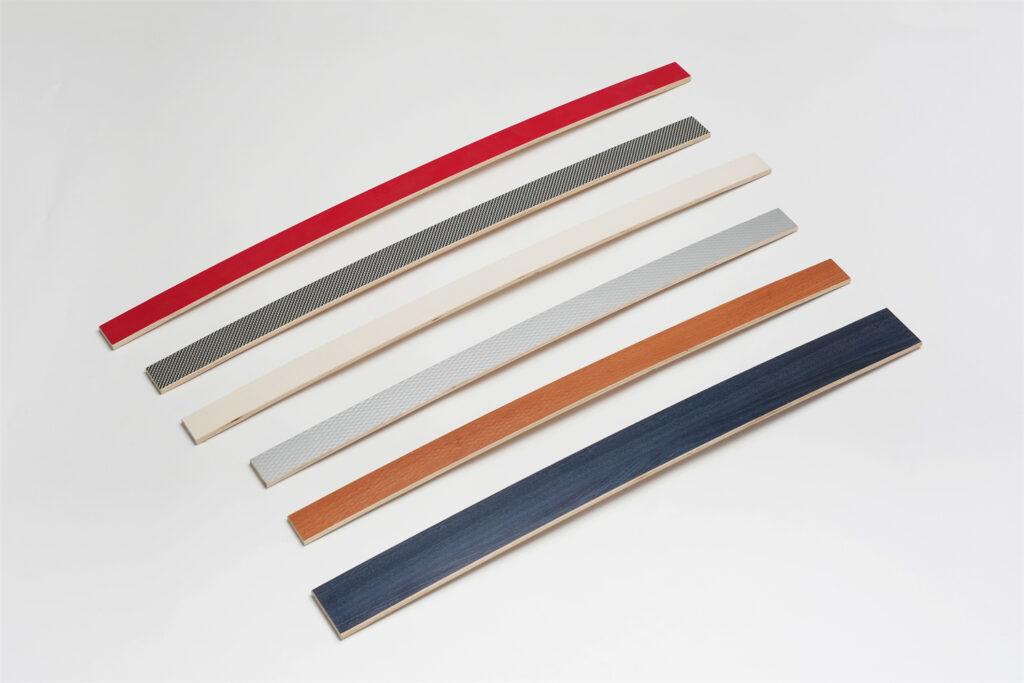

- Finishing Options: Provide a range of finishing options to match different bed frame styles and customer preferences. This could include natural finishes that showcase the beauty of the wood grain, stained finishes to achieve specific color tones, or lacquered finishes for added durability and protection.

- Packaging and Labeling: Elevate your brand presentation and streamline your logistics with customized packaging and labeling services. This could include printing your logo, product information, and assembly instructions directly on the packaging, creating a more professional and cohesive brand experience.

- Drop Shipping: Simplify your fulfillment process and reduce your shipping costs by partnering with a manufacturer that offers drop shipping services. This means the slats are shipped directly from the manufacturer to your customer, eliminating the need for you to handle inventory or manage shipping logistics.

Why Choose Yuantuo Wood for Your Custom Bed Slats?

Because we understand that in the competitive world of furniture, a good night’s sleep starts with a solid foundation – and so does a successful brand. At Yuantuo Wood, we don’t just manufacture bed slats; we craft tailor-made solutions that elevate your brand and provide your customers with the unparalleled sleep experience they deserve.

Here’s how Yuantuo Wood becomes your trusted partner in crafting the perfect sleep support:

- Meeting Your Diverse Manufacturing Needs: Just as custom bed slats are tailored to individual sleep preferences, our approach is tailored to your unique manufacturing processes. We collaborate closely with you to understand your production volume, design specifications, and material preferences, ensuring seamless integration and optimal efficiency.

- Sourcing the Finest, Crafting the Exceptional: We believe in the power of quality materials. Whether you prefer the timeless elegance of solid wood, the cost-effectiveness of durable plywood, or the sleek modernity of metal, we source the finest options to meet your exact requirements. Our skilled craftsmen then meticulously shape and finish each slat, ensuring exceptional durability and a flawless finish that reflects your brand’s commitment to excellence.

- Streamlining Your Supply Chain, Maximizing Your Value: We recognize that time and efficiency are essential for your business. That’s why we’ve optimized our manufacturing processes to deliver your custom bed slats precisely when and where you need them. Our flexible ordering options, competitive pricing, and reliable delivery schedules allow you to streamline your inventory, reduce costs, and focus on what matters most – crafting exceptional beds and growing your brand.

- Beyond the Slats: A Partnership Built on Trust: At Yuantuo Wood, our commitment to your success extends beyond production. We offer a range of value-added services, including just-in-time delivery, direct shipping to your assembly facilities, and customized packaging solutions, all designed to simplify your operations and enhance your brand experience.

Choose Yuantuo Wood and experience the difference that tailor-made solutions can make. Let us help you build a foundation for success – one perfect bed slat at a time.Click here to contact us.

FAQs: Your Custom Bed Slat Questions Answered

1. What types of beds are best suited for custom bed slats?

Custom bed slats are incredibly versatile and can be tailored to virtually any bed frame and mattress type. Whether you’re manufacturing platform beds, slatted bed frames, adjustable beds, or even bunk beds, custom slats can be designed to meet your specific requirements. They’re an excellent choice for all mattress types, including memory foam, latex, innerspring, and hybrid mattresses.

2. How do I determine the correct slat spacing for my bed frames?

The ideal slat spacing depends on the type of mattress and the desired level of support. For foam mattresses, which require a more solid foundation, closer slat spacing (around 2-3 inches apart) is recommended. For innerspring mattresses, which have built-in support structures, wider spacing (around 4-5 inches apart) can be used. Your custom slat manufacturer can advise on the optimal spacing based on your specific bed frame and mattress specifications.

3. Can custom bed slats accommodate heavier weight capacities?

Absolutely! Custom bed slats can be engineered to support a wide range of weight capacities. By adjusting factors like slat width, thickness, material, and support rail placement, manufacturers can create robust slat systems that provide reliable support for even the heaviest mattresses and individuals.

4. What are the advantages of offering pre-drilled bed slats?

Pre-drilled bed slats streamline the assembly process for both your customers and your assembly team. Pre-drilling ensures accurate hole placement, reduces the risk of splitting or damaging the slats during assembly, and eliminates the need for customers to have tools on hand. This translates to a faster, easier, and more user-friendly assembly experience.

5. Does ordering custom bed slats mean longer lead times?

Not necessarily. While custom orders typically require some additional production time compared to off-the-shelf options, many custom bed slat manufacturers offer competitive lead times. By partnering with a manufacturer that prioritizes efficiency and has a streamlined production process, you can often receive your custom slats within a reasonable timeframe that aligns with your production schedules.