Foil paper LVL (Laminated Veneer Lumber) slats are rapidly emerging as a game-changer in the construction industry, captivating builders and architects alike with their unique blend of strength, moisture resistance, and thermal performance. This innovative building material represents a significant leap forward, combining the inherent structural integrity of LVL with the protective and insulating properties of foil paper. This potent combination results in a versatile solution capable of meeting the demanding requirements of modern construction across a wide range of applications. This comprehensive exploration delves deep into the intricacies of foil paper LVL slats, meticulously examining their composition, dissecting the benefits they offer, showcasing their diverse applications, and ultimately, revealing their potential to transform the building landscape.

Unveiling the Composition: A Closer Look at Foil Paper LVL Slats

Understanding the remarkable performance of foil paper LVL slats begins with unraveling their unique composition. This innovative building material is meticulously engineered, representing a harmonious fusion of three primary components, each playing a critical role in the material’s overall performance:

- LVL Core: The Backbone of Strength: At the heart of every foil paper LVL slat lies a core of exceptional strength and dimensional stability, the very foundation upon which its remarkable properties are built. This core comprises multiple layers of thin wood veneer, typically sourced from readily available and sustainably harvested softwood species such as spruce, pine, or fir. These veneers, carefully selected for their straight grain and inherent strength, are then stacked with their grain running parallel, a defining characteristic of LVL that sets it apart from traditional lumber. This deliberate alignment of wood fibers maximizes their tensile strength, resulting in a material far stronger and more stable than solid lumber of comparable dimensions. To bind these veneer layers together, strong, moisture-resistant adhesives are applied, and the entire assembly is subjected to intense heat and pressure. This process fuses the veneer layers into a single, solid unit, creating the robust LVL core that forms the backbone of the foil paper LVL slat.

- Foil Paper Facing: The Protective Shield: Encasing the robust LVL core is a layer of foil paper, meticulously laminated to one or both sides of the slat. This specialized paper, specifically engineered for building applications, typically consists of three key layers: kraft paper, aluminum foil, and a bonding agent. The kraft paper, renowned for its durability and tear resistance, forms the outer layer, providing a robust shield against physical damage and abrasion. Sandwiched between the kraft paper and the LVL core lies the aluminum foil, the unsung hero behind the material’s exceptional thermal performance. This thin yet mighty layer acts as a radiant barrier, effectively reflecting radiant heat away from the surface. This reflective property helps regulate temperature, keeping buildings cooler in the summer and warmer in the winter, ultimately contributing to significant energy savings.

- Bonding Agent: The Unsung Hero of Cohesion: While often overlooked, the bonding agent plays a critical role in the structural integrity and long-term performance of foil paper LVL slats. This specialized adhesive, carefully selected for its compatibility with both LVL and foil paper, is responsible for creating a secure and lasting bond between these two distinct materials. The adhesive must possess exceptional strength to withstand the stresses and strains encountered in building applications, ensuring that the foil paper facing remains firmly attached to the LVL core throughout the lifespan of the structure. Furthermore, it needs to maintain its integrity under varying temperature and humidity conditions, preventing delamination or weakening of the bond, which could compromise the material’s overall performance.

5 Key Advantages of Foil Paper LVL Slats

The unique composition of foil paper LVL slats, a testament to engineering ingenuity, gives rise to a compelling set of advantages that elevate them above conventional building materials. These advantages, rooted in the synergistic interplay of their constituent components, make them a superior choice for a diverse array of building applications:

- Exceptional Strength and Stability: A Solid Foundation for Building: The LVL core, the very heart of foil paper LVL slats, is engineered for exceptional strength and dimensional stability, surpassing traditional lumber by a significant margin. This inherent strength translates into superior load-bearing capacity, allowing foil paper LVL slats to span greater distances without the need for excessive intermediate supports. This not only simplifies construction but also allows for greater design flexibility, enabling architects to create more open and spacious interiors. Moreover, the dimensional stability of LVL ensures that foil paper LVL slats resist warping, twisting, and shrinking over time, maintaining their structural integrity and ensuring the longevity of the building.

- Superior Moisture Resistance: Shielding Structures from the Elements: Moisture is a relentless adversary to building materials, often leading to rot, decay, and mold growth, ultimately compromising structural integrity and shortening the lifespan of buildings. Foil paper LVL slats, however, are engineered to stand strong against this persistent threat, thanks to the exceptional moisture resistance offered by the foil paper facing. This protective layer acts as a formidable vapor barrier, effectively preventing moisture from penetrating the LVL core, even in challenging environmental conditions. This inherent moisture resistance makes foil paper LVL slats particularly well-suited for applications in humid climates or areas prone to heavy rainfall, where protecting building materials from moisture damage is paramount.

- Enhanced Thermal Performance: Building for Energy Efficiency: In an era where energy efficiency is no longer an option but a necessity, foil paper LVL slats emerge as a champion of sustainability. The aluminum foil layer embedded within the foil paper facing plays a pivotal role in enhancing the thermal performance of buildings. This thin yet remarkably effective layer acts as a radiant barrier, reflecting radiant heat away from the building envelope. This means that during the scorching summer months, foil paper LVL slats help to keep buildings cooler by reflecting the sun’s radiant heat away, reducing the reliance on energy-intensive air conditioning systems. Conversely, during the colder winter months, they help to retain heat within the building, minimizing heat loss and reducing the need for excessive heating. This ability to regulate temperature translates into significant energy savings over the lifespan of the building, reducing both energy costs and the overall environmental impact.

- Improved Indoor Air Quality: Building for Health and Well-being: The quest for sustainable building practices extends beyond energy efficiency to encompass the health and well-being of occupants. Foil paper LVL slats, with their exceptional moisture resistance, contribute to healthier indoor environments by mitigating the risk of mold growth. Mold, a common problem in buildings with moisture issues, can release spores into the air, triggering allergies and respiratory problems in susceptible individuals. The foil paper facing, acting as a vapor barrier, helps to prevent condensation and moisture buildup within walls and roofs, depriving mold of the damp environment it needs to thrive. This inherent ability to inhibit mold growth makes foil paper LVL slats particularly beneficial in areas with high humidity levels or for buildings prone to moisture problems, ensuring a healthier and more comfortable living or working environment for occupants.

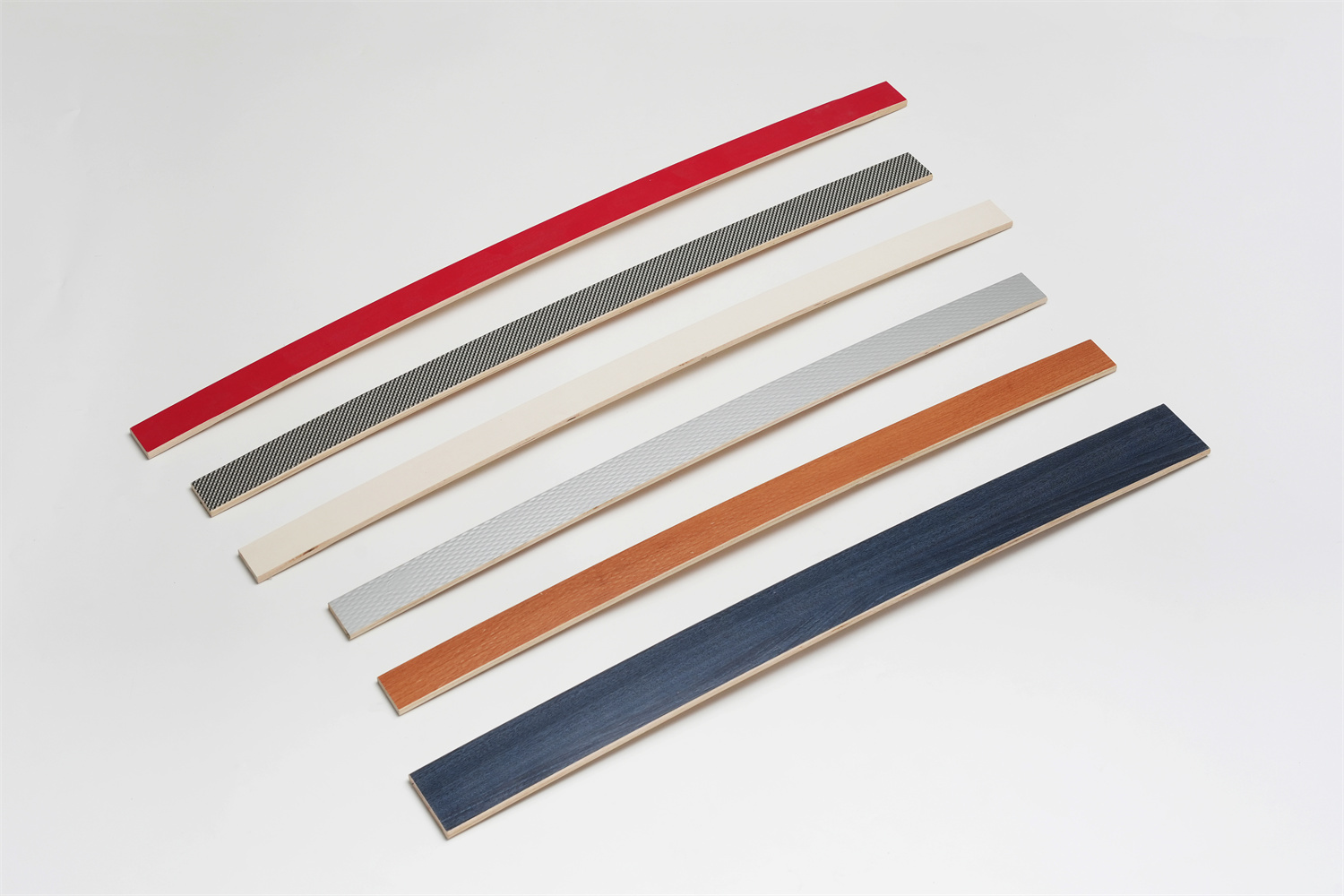

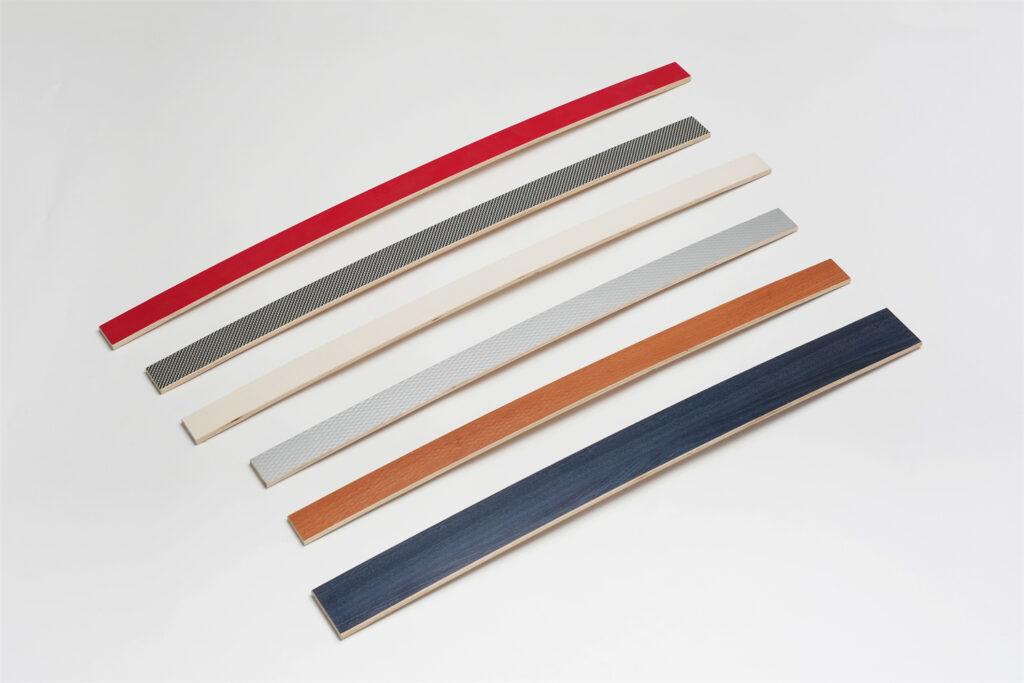

- Versatility and Ease of Installation: Streamlining Construction: Foil paper LVL slats, beyond their impressive performance attributes, are also designed for ease of use and installation, streamlining the construction process and reducing labor costs. They are manufactured in a wide range of lengths, widths, and thicknesses, providing builders with the flexibility to select the ideal dimensions for their specific project requirements. Their lightweight nature, compared to traditional lumber or steel framing, makes them easier to handle and maneuver on the construction site, reducing the need for heavy machinery and simplifying installation. Moreover, the consistent dimensions of foil paper LVL slats, a testament to the precision of the manufacturing process, ensure uniformity and predictability during installation, minimizing waste and reducing the need for on-site adjustments.

Applications of Foil Paper LVL Slats: Where Innovation Meets Functionality

The unique convergence of strength, moisture resistance, and thermal performance in foil paper LVL slats unlocks a world of possibilities in building and construction. Their versatility shines through in a wide range of applications, demonstrating their adaptability and effectiveness in diverse building scenarios:

1. Roofing: A Strong and Energy-Efficient Foundation: Foil paper LVL slats are rapidly gaining popularity as a superior alternative to traditional lumber for roof rafters and purlins. Their exceptional strength-to-weight ratio allows them to span greater distances, reducing the need for intermediate supports and allowing for more open attic spaces. The foil paper facing, with its radiant barrier properties, helps to reflect heat away from the attic, keeping the living space below cooler in the summer months and reducing the load on air conditioning systems. This translates into significant energy savings and a more comfortable living environment for homeowners.

2. Walls: Building Envelopes that Breathe and Protect: As wall studs and headers, foil paper LVL slats provide the structural backbone of the building envelope while simultaneously enhancing its energy efficiency and moisture resistance. Their superior strength allows for taller walls and larger window openings, providing greater design freedom for architects. The foil paper facing, acting as a vapor barrier, prevents moisture intrusion from the exterior, protecting the wall cavity and insulation from moisture-related damage. This ensures the long-term performance of the building envelope and contributes to a healthier indoor environment.

3. Flooring: A Stable and Comfortable Foundation Underfoot: Foil paper LVL slats are increasingly being employed as floor joists, providing a strong and stable base for subfloors and flooring materials. Their dimensional stability ensures that floors remain level and free from squeaks or bounces over time, even under heavy loads. The foil paper facing can also contribute to improved thermal comfort by acting as a radiant barrier, reflecting heat back into the living space during the colder months, creating a cozier and more energy-efficient environment.

4. Shipping Containers: Withstanding the Rigors of Global Transport: The durability, moisture resistance, and dimensional stability of foil paper LVL slats make them ideally suited for the construction of shipping containers, which must withstand the rigors of global transportation, often exposed to harsh environmental conditions. The foil paper facing helps to protect the contents of the container from moisture damage and temperature fluctuations, ensuring that goods arrive at their destination in optimal condition. The structural integrity of foil paper LVL slats also contributes to the overall strength and longevity of the shipping container, extending its lifespan and reducing the need for frequent replacements.

5. Agricultural Buildings: Creating Optimal Environments for Livestock and Crops: In agricultural settings, where controlling temperature and humidity levels is crucial for the health and productivity of livestock and crops, foil paper LVL slats offer a compelling solution. They are used to construct barns, stables, poultry houses, and other agricultural structures, providing a durable, moisture-resistant, and thermally efficient building envelope. The foil paper facing helps to regulate the internal environment, protecting animals and stored goods from extreme temperatures and humidity, creating a more comfortable and productive environment.

Comparing Foil Paper LVL Slats to Other Building Materials

To fully grasp the significance of foil paper LVL slats as a revolutionary building material, it’s essential to compare them to other commonly used options, highlighting their strengths and weaknesses relative to the competition:

| Feature | Foil Paper LVL Slats | Traditional Lumber | Steel Framing | Insulated Concrete Forms (ICFs) |

|---|---|---|---|---|

| Strength | High | Moderate | High | Very High |

| Moisture Resistance | Excellent | Poor to Moderate | Excellent | Excellent |

| Thermal Performance | Good | Poor | Poor | Excellent |

| Cost | Moderate | Low | High | High |

| Sustainability | Good | Moderate | Moderate | Good |

Foil Paper LVL Slats: Represent a compelling balance of desirable attributes, offering high strength, excellent moisture resistance, good thermal performance, and moderate cost, all while maintaining a respectable sustainability profile. This balance makes them an incredibly versatile choice for a wide range of applications, often outperforming traditional lumber and offering a more cost-effective alternative to steel framing or ICFs in many scenarios.

Traditional Lumber: While still widely used due to its affordability and familiarity, traditional lumber falls short in several key areas compared to foil paper LVL slats. Its strength and dimensional stability are inherently limited by the natural variations and imperfections found in solid wood, making it susceptible to warping, twisting, and shrinking over time. Additionally, its moisture resistance is relatively poor, requiring chemical treatments to enhance its longevity, which can raise environmental concerns.

Steel Framing: Steel framing excels in strength, durability, and moisture resistance, making it a popular choice for commercial and industrial buildings. However, its thermal performance is inherently poor, requiring additional insulation to achieve desired energy efficiency levels. Steel is also susceptible to corrosion, especially in coastal environments or areas with high humidity, necessitating protective coatings that add to its overall cost.

Insulated Concrete Forms (ICFs): ICFs represent the pinnacle of thermal performance and structural strength, offering exceptional energy efficiency and resistance to fire, wind, and seismic forces. However, their high cost and specialized installation requirements often make them cost-prohibitive for residential construction or projects with budget constraints.

Factors Influencing the Performance of Foil Paper LVL Slats

While foil paper LVL slats offer a compelling combination of performance advantages, several factors can influence their overall effectiveness and longevity, highlighting the importance of careful material selection, proper installation practices, and consideration of environmental conditions:

- Quality of Materials: The Foundation of Performance: The old adage “you get what you pay for” rings true in the world of building materials. The quality of the LVL core, foil paper facing, and bonding agent directly impacts the overall performance and lifespan of the foil paper LVL slat. Opting for high-quality materials from reputable manufacturers ensures that the LVL core possesses the desired strength and dimensional stability, the foil paper facing provides a robust vapor barrier and effective radiant barrier, and the bonding agent creates a secure and lasting bond between these components.

- Manufacturing Process: Precision Engineering for Consistent Quality: The manufacturing process plays a crucial role in determining the quality and consistency of foil paper LVL slats. Precise control over veneer layering, adhesive application, pressing, and curing ensures that each slat meets stringent performance standards. Advanced manufacturing techniques, such as continuous pressing and radio-frequency curing, contribute to the production of high-performance LVL slats with uniform properties and exceptional bond strength between the LVL core and the foil paper facing.

- Installation Practices: Maximizing Performance Through Proper Execution: Even the highest quality building materials can fail to deliver their full potential if not installed correctly. Proper installation is paramount to maximizing the performance and longevity of foil paper LVL slats. This includes ensuring proper spacing between slats to accommodate load-bearing requirements, using appropriate fasteners designed for LVL, and employing proper sealing techniques to prevent moisture intrusion at joints and connections. Adhering to manufacturer recommendations and industry best practices during installation is crucial to ensure that the structural integrity and performance benefits of foil paper LVL slats are fully realized.

- Environmental Conditions: Understanding the Limits of Material Performance: While foil paper LVL slats offer excellent moisture resistance, it’s essential to recognize that they are not impervious to the effects of prolonged exposure to extreme humidity or standing water. In applications where constant moisture contact is a concern, such as below-grade construction or areas with inadequate drainage, additional protective measures may be necessary. Proper drainage and ventilation are crucial in preventing moisture-related issues, ensuring that foil paper LVL slats can perform optimally and maintain their structural integrity over time.

Frequently Asked Questions about Foil Paper LVL Slats

1. What is the lifespan of foil paper LVL slats compared to traditional lumber?

Foil paper LVL slats, with their superior moisture resistance and dimensional stability, typically boast a significantly longer lifespan than traditional lumber, especially in demanding applications or humid environments. While traditional lumber may be susceptible to rot, decay, or warping over time, foil paper LVL slats can resist these issues, often lasting decades longer with proper installation and maintenance.

2. Can foil paper LVL slats be left exposed to the elements during construction?

While foil paper LVL slats offer excellent moisture resistance, prolonged exposure to rain, snow, or direct sunlight during construction is not recommended. It’s best practice to cover them with a tarp or other protective barrier when not actively being worked on to prevent potential damage or deterioration of the foil paper facing.

3. Are there any special tools or skills required to install foil paper LVL slats?

Foil paper LVL slats can typically be installed using standard carpentry tools and techniques similar to those used for traditional lumber. However, it’s essential to consult the manufacturer’s installation guidelines and use fasteners specifically designed for LVL to ensure proper structural integrity.

4. Can foil paper LVL slats be used in load-bearing applications?

Absolutely! Foil paper LVL slats are engineered for exceptional strength and are often used in load-bearing applications such as roof rafters, floor joists, and wall studs. Their superior strength-to-weight ratio allows them to span greater distances and support heavier loads compared to traditional lumber.

5. Is foil paper LVL a sustainable building material?

Yes, foil paper LVL is considered a sustainable building material. The LVL core is typically sourced from sustainably managed forests, and the manufacturing process is designed to minimize waste. Additionally, the enhanced thermal performance of foil paper LVL slats contributes to energy savings over the lifespan of the building, further reducing its environmental impact.

The Future of Building: Foil Paper LVL Slats Leading the Way

Foil paper LVL slats stand as a testament to the relentless pursuit of innovation in the construction industry, offering a glimpse into the future of building materials. Their unique combination of strength, moisture resistance, thermal performance, and sustainability positions them as a key driver in the shift towards more efficient, durable, and environmentally responsible building practices. As architects, builders, and homeowners increasingly seek solutions that address multiple performance requirements while minimizing environmental impact, foil paper LVL slats are poised to play an increasingly prominent role in shaping the buildings of tomorrow. Their ability to deliver exceptional performance across a wide range of applications, coupled with their ease of use and sustainable attributes, makes them a compelling choice for those seeking to build a better future, one slat at a time.