LVL Slats For Packing

LVL slats, engineered for superior strength and stability, are the robust backbone of efficient and secure packaging. Crafted from laminated veneer lumber, these slats resist warping and twisting, ensuring the integrity of your goods. Ideal for crating, palletizing, and reinforcing shipping boxes, LVL slats offer a lightweight yet durable solution for transporting heavy machinery, fragile goods, and everything in between. Choose LVL slats for packaging excellence that prioritizes both protection and sustainability.

Customization

Tailor products to meet your specific requirements.

Manufacturing

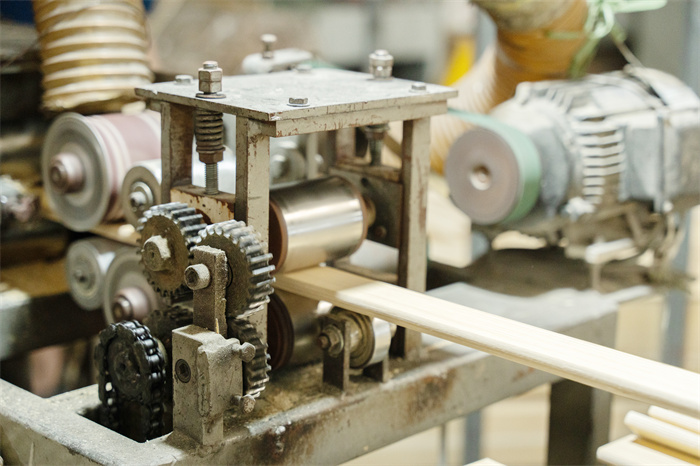

Consistent, durable products crafted with advanced techniques.

Logistics

Ensuring timely delivery to our clients worldwide.

share this product

In the intricate world of packaging and shipping, where the safe arrival of goods is paramount, the choice of materials plays a crucial role. LVL slats, engineered for superior strength, dimensional stability, and versatility, have emerged as a game-changer in the packaging industry. These remarkable wood products are transforming the way we protect and transport goods, offering a reliable and sustainable alternative to traditional packaging materials. This comprehensive guide delves deep into the world of LVL slats for packing, exploring their construction, advantages, diverse applications, and why YuanTuo Wood stands as a trusted partner in delivering premium-quality LVL slats that elevate your packaging solutions.

What are LVL Slats for Packing?

Deconstructing LVL Technology

LVL, an acronym for Laminated Veneer Lumber, represents the pinnacle of engineered wood technology. Unlike solid lumber, which can be susceptible to inconsistencies in strength, warping, and splitting, LVL is meticulously crafted through a sophisticated process. Thin sheets of wood veneer, typically sourced from sustainably harvested softwood species like Pine, Spruce, or Fir, are bonded together using high-strength, moisture-resistant adhesives. This bonding process occurs under carefully controlled heat and pressure, resulting in a material that transcends the limitations of its natural counterpart.

The secret to LVL’s exceptional strength and stiffness lies in the strategic alignment of the wood grain. Each veneer layer is positioned with its grain running in the same direction, creating a homogenous, cross-laminated structure that is exceptionally resistant to warping, twisting, and bowing – attributes highly sought after in demanding packaging applications. This engineered consistency ensures that LVL slats provide reliable performance and structural integrity, protecting valuable goods throughout their journey.

LVL Slats: Engineered for Packaging Excellence

LVL slats for packing are specifically engineered to provide robust support and protection for goods during the rigors of transit and storage. Their exceptional strength-to-weight ratio allows them to withstand the stresses of handling, stacking, and transportation, ensuring that packaged items remain secure and undamaged. This is particularly crucial when shipping heavy or fragile goods that are susceptible to damage from impact or vibration.

Beyond their strength, LVL slats offer a smooth, splinter-free surface that safeguards the integrity of packaged goods. This smooth surface prevents snags, tears, or abrasions that could occur with rougher packaging materials, ensuring that products arrive at their destination in pristine condition. Available in various thicknesses, widths, and lengths, LVL slats can be customized to accommodate a wide range of package sizes and weights, providing a tailored packaging solution for diverse needs.

Technical Specifications of LVL Slats for Packing

| Feature | Description |

| Wood Species | Poplar |

| Properties |

Characterized by an impressive strength-to-weight ratio, exceptional dimensional stability, remarkable resistance to warping, twisting, and shrinking, and the ability to be treated for fire retardancy or insect resistance upon request. The consistent quality and predictable performance of LVL make it a superior choice for demanding packaging applications where structural integrity and reliability are paramount.

|

| Surface Finish | Natural |

| Type | Flat |

| Dimensions |

Length:550-1750mm

Width:25-170mm Thickness:6-20mm |

| Glue Grade | E0, E1 |

| Moisture Content | 8-14% |

| Certificate |

FSC/ CARB P2/ EPA

|

Applications of LVL Slats in Packaging

LVL slats have become an indispensable component in a wide array of packaging applications, providing robust and reliable solutions for protecting goods across various industries. Their versatility, strength, and dimensional stability make them suitable for a diverse range of packaging needs, from lightweight consumer goods to heavy-duty industrial equipment. Here’s a closer look at some of the key applications where LVL slats excel:

- Crating: The Backbone of Secure Transport

LVL slats are the backbone of robust crates used to transport heavy machinery, industrial equipment, sensitive electronics, and other bulky or high-value items. Their exceptional strength-to-weight ratio allows them to withstand the rigors of long-distance shipping, rough handling, and stacking, ensuring that the contents of the crate remain protected from impact, vibration, and compression forces. The dimensional stability of LVL slats is particularly crucial in crating applications, as it prevents the crate from warping or twisting, which could compromise its structural integrity and jeopardize the safety of the goods inside.

- Palletizing: Elevating Efficiency and Reliability

In the realm of palletizing, where efficiency and reliability are paramount, LVL slats are rapidly gaining traction as a superior alternative to traditional wood pallets. Their consistent dimensions and resistance to warping make them ideal for use in automated palletizing systems, where precision and consistency are essential for smooth operation. LVL slats’ ability to withstand heavy loads and resist moisture makes them well-suited for creating durable pallets that can be safely stacked, ensuring the stability of goods during storage and transportation.

- Shipping Boxes: Reinforcing Protection for Fragile Goods

LVL slats can be strategically incorporated into the design of heavy-duty shipping boxes to provide reinforcement and prevent crushing, particularly for fragile or high-value items that require extra protection during transit. By adding LVL slats as internal bracing or external reinforcement, the structural integrity of the box is significantly enhanced, safeguarding its contents from damage caused by impact, stacking, or rough handling. This is especially important for items like electronics, glassware, artwork, and other delicate goods that are susceptible to damage during shipping.

- Furniture Protection: Safeguarding Delicate Craftsmanship

The furniture industry, with its focus on craftsmanship and delicate finishes, relies heavily on LVL slats for the safe transportation and storage of furniture pieces. LVL slats can be used to create internal bracing within furniture packaging, safeguarding delicate components from impact or vibration during transit. They can also be used to construct external crates or frames that provide overall protection for larger furniture pieces, such as sofas, tables, and armoires. Their smooth surface prevents scratches or dents on delicate finishes, ensuring that furniture arrives at its destination in pristine condition.

- Construction and Building Materials: Ensuring On-Site Integrity

The construction industry utilizes LVL slats for the packaging and protection of a wide range of building materials, including doors, windows, countertops, flooring, and prefabricated wall panels. Their strength and stability ensure that these materials, often heavy and bulky, are transported and handled safely, preventing damage that could lead to costly delays or rework on the construction site. LVL slats’ resistance to moisture and warping is particularly beneficial in this application, as it ensures that building materials are protected from the elements during transportation and storage.

- Automotive Parts: Protecting Precision Engineering

The automotive industry relies on the precision and durability of LVL slats for the secure packaging and transportation of various car parts, including engines, transmissions, body panels, windshields, and other sensitive components. Their strength and dimensional stability protect these valuable components from damage during shipping and handling, ensuring that they arrive at assembly plants or repair shops in optimal condition. The use of LVL slats in automotive packaging helps minimize the risk of damage, reducing costly delays and maintaining the integrity of the automotive supply chain.

- Export Packaging: Meeting International Standards

LVL slats are a popular choice for export packaging due to their compliance with international phytosanitary standards, such as ISPM 15. These standards regulate the use of wood packaging materials in international trade to prevent the spread of plant pests and protect forests worldwide. LVL slats can be heat-treated or fumigated to meet these requirements, ensuring smooth customs clearance and preventing delays in the supply chain. Their use in export packaging demonstrates a commitment to environmental responsibility and global trade compliance.

Advantages of LVL Slats for Packing

-

Exceptional Strength and Durability: The cross-laminated construction of LVL slats results in exceptional strength and durability, allowing them to withstand the rigors of transportation and handling. This ensures that packaged goods remain protected from impact, vibration, and compression forces encountered during transit.

-

Dimensional Stability: LVL slats are highly resistant to warping, twisting, and shrinking, even in fluctuating temperatures and humidity levels. This dimensional stability ensures that packages maintain their structural integrity, preventing damage to goods due to shifting or collapsing packaging.

-

Lightweight Yet Strong: Despite their impressive strength, LVL slats are relatively lightweight, making them easier to handle and assemble into packaging structures. This can reduce shipping costs and make the packaging process more efficient.

-

Versatility in Design: LVL slats can be easily cut, shaped, and assembled into various packaging configurations, providing flexibility in design to accommodate a wide range of product sizes and shapes. They can be used to create custom crates, boxes, pallets, and other packaging solutions tailored to specific needs.

-

Sustainable and Eco-Friendly: LVL is an environmentally responsible choice for packaging materials. It is manufactured using sustainably harvested wood resources, minimizing its environmental impact. Additionally, LVL slats can be recycled or disposed of responsibly at the end of their lifecycle, further reducing their ecological footprint.

Comparison with Other Packaging Materials

-

LVL Slats vs. Solid Wood: While solid wood is a traditional packaging material, it can be prone to warping, splitting, and inconsistencies in strength. LVL slats, with their engineered construction and consistent quality, offer superior strength, stability, and reliability, making them a more robust and dependable choice for demanding packaging applications.

-

LVL Slats vs. Plywood: Plywood, while strong, can be heavy and less dimensionally stable than LVL slats. LVL’s cross-laminated construction gives it superior strength-to-weight ratio and resistance to warping, making it a more efficient and reliable choice for packaging, especially for heavy-duty applications.

-

LVL Slats vs. Metal Packaging: Metal packaging, while strong, can be expensive, prone to corrosion, and may not be suitable for all types of goods. LVL slats offer a more cost-effective, lightweight, and versatile alternative, particularly for items that require cushioning or protection from moisture.

-

LVL Slats vs. Plastic Packaging: Plastic packaging, while lightweight and moisture-resistant, can be less environmentally friendly and may not offer the same level of strength and structural integrity as LVL slats. LVL slats provide a more sustainable and robust solution, especially for heavy or fragile goods.

Why Choose YuanTuo Wood for Your LVL Slat Needs?

At YuanTuo Wood, we are not merely a supplier of LVL slats for packing; we are your dedicated partners in safeguarding your valuable goods throughout their journey. Our unwavering commitment to quality, precision engineering, sustainable practices, and exceptional customer service distinguishes us as a leader in the industry.

-

Uncompromising Quality: Our state-of-the-art manufacturing facilities adhere to the most stringent quality control measures at every stage of production. From the selection of premium wood veneers to the precision bonding process, we ensure that every LVL slat that leaves our facility meets the highest industry standards for strength, durability, and dimensional accuracy. Our dedicated quality control team meticulously inspects each slat to guarantee it surpasses expectations.

-

Engineered for Excellence: Our team of experienced engineers and wood specialists work tirelessly to optimize the design and performance of our LVL slats for packing. We leverage the latest technologies and manufacturing techniques to create slats that are exceptionally strong, stable, and reliable, exceeding industry standards and meeting the specific demands of your packaging applications.

-

Sustainability at Our Core: We believe in responsible forestry practices and source our wood exclusively from sustainably managed forests. This commitment to environmental stewardship extends throughout our operations, encompassing efforts to minimize waste, reduce our carbon footprint, and promote eco-conscious practices. By choosing YuanTuo Wood, you are choosing a partner that prioritizes the health of our planet.

-

Customer-Centric Approach: Our dedication to customer satisfaction is unwavering. Our knowledgeable and responsive team is here to guide you through every step of the process, from initial inquiry to final delivery. We are committed to building lasting relationships based on trust, transparency, and a genuine desire to see your packaging solutions succeed.

FAQ

1. What is the load-bearing capacity of LVL slats for packing?

The load-bearing capacity of LVL slats varies depending on factors such as slat dimensions, spacing, and the overall design of the packaging structure. Our team of engineers can work with you to determine the appropriate slat specifications and configuration to meet your specific load requirements.

2. Can LVL slats be treated for fire retardancy?

Yes, LVL slats can be treated with fire-retardant chemicals to meet specific fire safety regulations. These treatments enhance the fire resistance of the slats, making them suitable for applications where fire safety is a concern.

3. Are LVL slats ISPM 15 compliant for international shipping?

Yes, our LVL slats can be heat-treated or fumigated to comply with ISPM 15 regulations for international shipping. This ensures that our slats meet the phytosanitary standards required to prevent the spread of plant pests and facilitate smooth customs clearance.

4. Can LVL slats be customized with branding or markings?

Yes, we offer customization options for our LVL slats, including branding, markings, or special treatments. This allows you to enhance brand visibility, provide important shipping information, or meet specific product identification requirements.

5. What is the lead time for LVL slat orders?

Lead times for LVL slat orders vary depending on order volume, customization requirements, and current production schedules. Our sales team will provide you with an estimated lead time based on your specific order details.

Conclusion

In the ever-evolving landscape of packaging and shipping, where efficiency, security, and sustainability converge, LVL slats have emerged as an indispensable component. Their exceptional strength, dimensional stability, versatility, and eco-friendly nature make them the ideal choice for safeguarding goods during transit and storage, providing peace of mind to businesses and customers alike. By choosing YuanTuo Wood as your partner in packaging, you benefit from our unwavering commitment to quality, precision engineering, sustainable practices, and exceptional customer service. We are dedicated to providing you with LVL slat solutions that exceed expectations and contribute to a more secure and sustainable future for the packaging industry.

01.

Veneer

High-quality veneer sheets are selected as the base material.

02.

Veneer Drying

Dried to the ideal moisture content for stability.

03.

Glue Spreading

Applied evenly to ensure a strong bond between layers.

04.

Assembly

Glued sheets are aligned and layered for pressing.

05.

Cold Press Forming

Layers are cold-pressed to set the initial bond.

06.

Hot press

High pressure and heat finalize the bond and product shape.

07.

Cutting edge

Boards are trimmed to exact dimensions.

08.

Cutting

Trimmed boards are cut to specific sizes.

09.

Chamfering

Edges are smoothed for a clean finish.

10.

Nail the straps

Straps are added for strength and easy handling.

11.

Packing

Products are carefully packed for protection.

12.

Delivery

Finished products are shipped to customers.