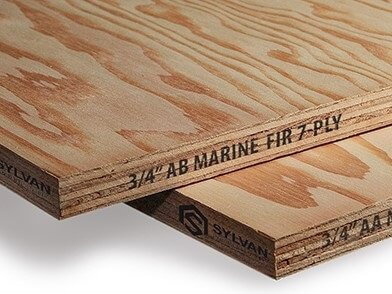

O sabor do ar salgado, o grito das gaivotas por cima, o balanço suave de um barco nas ondas... Dedicou-se de corpo e alma à conceção da embarcação ou estrutura marítima perfeita. Mas mesmo o projeto mais deslumbrante precisa dos materiais certos para se tornar realidade. E quando se trata de construção marítima, há um material que se destaca dos restantes: marinha contraplacado.

Mas nem todo o contraplacado marítimo é criado da mesma forma. É necessário um fornecedor que compreenda a natureza exigente dos ambientes marítimos, um fornecedor que ofereça qualidade sem afundar o seu orçamento. E é aí que entra a China.

Porquê escolher a China para contraplacado marítimo?

A China emergiu como líder mundial no fabrico de contraplacado, e o contraplacado marítimo não é exceção. Eis a razão pela qual os construtores, arquitectos e entusiastas do sector marítimo mais exigentes estão a orientar-se para a China:

- Valor imbatível: Beneficie de preços competitivos sem comprometer a qualidade. Os fabricantes chineses tiram partido de processos de produção eficientes e de economias de escala para oferecerem soluções económicas, tornando os seus sonhos marítimos mais realizáveis.

- Qualidade excecional: Não se deixe enganar por noções preconcebidas! Os fabricantes chineses de contraplacado marítimo intensificaram o seu jogo, investindo fortemente em tecnologia avançada e em medidas rigorosas de controlo de qualidade. Este compromisso com a qualidade garante que recebe contraplacado marítimo que cumpre os mais elevados padrões internacionais, proporcionando o desempenho e a durabilidade que o seu projeto exige.

- Um mar de escolhas: Desde tamanhos padrão a cortes personalizados, uma vasta rede de fornecedores oferece uma gama diversificada de opções de contraplacado marítimo para se adequar a cada projeto e orçamento. Quer esteja a construir um iate de luxo, um barco de pesca robusto ou uma doca resistente, encontrará o contraplacado marítimo perfeito para dar vida à sua visão.

Navegando nas águas: Factores-chave na escolha de um fornecedor

Com uma multiplicidade de fornecedores de contraplacado marítimo na China, encontrar a combinação perfeita para as suas necessidades requer uma análise cuidadosa. Aqui está a sua bússola para navegar no processo de seleção:

- Qualidade em primeiro lugar - sempre:

- As certificações são importantes: Procure fornecedores certificados por organizações internacionais de renome, que garantam o cumprimento de normas ambientais e de qualidade rigorosas. As principais certificações a procurar incluem:

- BS 1088: O padrão de ouro para o contraplacado marítimo, garantindo durabilidade e resistência à delaminação em condições húmidas e molhadas, essenciais para estruturas marítimas duradouras.

- Em conformidade com a Fase 2 do CARB: Garante baixas emissões de formaldeído, cruciais para aplicações em interiores e para o bem-estar da tripulação, especialmente em espaços de cabina fechados.

- Não salte o pedido de amostras: O pedido de amostras permite-lhe avaliar fisicamente a qualidade do contraplacado, verificando aspectos cruciais como:

- Superfícies lisas e sem vazios: Essencial para um acabamento impecável e uma durabilidade duradoura, evitando a infiltração de água e garantindo um aspeto profissional.

- Folheados de núcleo consistente: Indica a integridade estrutural e a resistência à deformação, essencial para manter a integridade estrutural da sua embarcação ou estrutura marítima.

- Forte qualidade das obrigações: Garante que o contraplacado resiste às exigentes condições marítimas, evitando a delaminação e assegurando uma longa vida útil para o seu projeto.

- As certificações são importantes: Procure fornecedores certificados por organizações internacionais de renome, que garantam o cumprimento de normas ambientais e de qualidade rigorosas. As principais certificações a procurar incluem:

- A experiência conta:

- Experiência no sector: Procure fornecedores com um historial comprovado no sector do contraplacado marítimo. A experiência equivale a uma compreensão profunda dos desafios e requisitos únicos das aplicações marítimas, assegurando que podem fornecer soluções à medida das suas necessidades específicas.

- Testemunhos de clientes e projectos: O portefólio de um fornecedor diz muito. Procure estudos de casos, testemunhos ou exemplos de projectos anteriores que demonstrem a sua experiência na indústria marítima. É mais provável que um fornecedor com um historial de projectos marítimos bem sucedidos compreenda os seus requisitos e forneça produtos de alta qualidade.

- Para além do contraplacado:

- A comunicação é fundamental: Escolha um fornecedor que dê prioridade a uma comunicação clara, rápida e profissional. As barreiras linguísticas nunca devem impedir o progresso do seu projeto, por isso procure fornecedores que sejam fluentes na sua língua preferida ou que tenham canais de comunicação dedicados.

- Especialização em logística e expedição: Navegar no transporte marítimo internacional pode ser complexo. Um fornecedor fiável deve ter experiência no manuseamento de documentação de exportação, desalfandegamento e logística, garantindo que o seu contraplacado chega em segurança e dentro do prazo. Informe-se sobre os seus parceiros de expedição e o seu historial para garantir um processo de entrega sem problemas.

Navegar para o sucesso: Fazendo seu pedido de compensado naval

Depois de ter traçado a sua rota e escolhido o seu fornecedor, é altura de zarpar com a sua encomenda. Eis uma lista de controlo para garantir uma navegação tranquila:

- As especificações são fundamentais: Fornecer especificações pormenorizadas para os seus requisitos de contraplacado, sem deixar margem para ambiguidades. Isto inclui:

- Tipo de madeira: Diferentes espécies de madeira oferecem diferentes níveis de força, durabilidade e resistência a brocas marinhas. As escolhas populares para contraplacado marítimo incluem:

- Okoume: É leve, fácil de trabalhar e naturalmente resistente à podridão e à deterioração, o que o torna ideal para a construção de barcos, especialmente para embarcações mais pequenas.

- Meranti: Durável e forte, frequentemente utilizado para componentes estruturais em barcos de maiores dimensões, docas e outras estruturas marítimas que requerem elevada resistência.

- Bétula: Conhecido pela sua resistência e pelo seu belo padrão de grão, é adequado para aplicações interiores em iates e outras embarcações marítimas topo de gama.

- Espessura e dimensões: Especifique a espessura e as dimensões exactas necessárias para o seu projeto para minimizar o desperdício e garantir um ajuste preciso, reduzindo a necessidade de modificações no local.

- Tipo de adesivo: O adesivo utilizado no contraplacado marítimo é crucial para as suas propriedades à prova de água. As colas WBP (Weather and Boil Proof) são essenciais para aplicações marítimas, assegurando que o contraplacado pode suportar uma exposição prolongada à humidade.

- Acabamento da superfície: Especifique quaisquer acabamentos de superfície desejados, como lixagem, revestimento ou folheados decorativos. Isto permite-lhe obter a estética e o nível de proteção desejados para o seu projeto.

- Tipo de madeira: Diferentes espécies de madeira oferecem diferentes níveis de força, durabilidade e resistência a brocas marinhas. As escolhas populares para contraplacado marítimo incluem:

- Quantidade e prazo de entrega: Comunique claramente a quantidade desejada e o prazo de entrega previsto para garantir que o fornecedor pode cumprir o calendário do seu projeto. Forneça prazos realistas e informe-se sobre a sua capacidade de produção para evitar atrasos.

- Condições de pagamento & Condições: Estabelecer termos e condições de pagamento claros, incluindo métodos de pagamento, requisitos de depósito e quaisquer direitos ou impostos de importação aplicáveis. Discuta a segurança do pagamento e certifique-se de que ambas as partes estão de acordo com os termos.

Traçar o seu percurso: Encontrar o fornecedor certo para si

Encontrar o fornecedor certo de contraplacado marítimo na China não tem de ser uma caça ao tesouro. Aqui está uma análise dos métodos de abastecimento mais comuns, cada um com as suas próprias vantagens e desvantagens:

| Método | Prós | Contras |

|---|---|---|

| Plataformas B2B em linha: | Conveniente, vasta seleção de fornecedores, acesso a classificações e críticas de fornecedores, muitas vezes com ferramentas de comunicação incorporadas | Pode ser difícil de navegar, pode haver fraudes, depende da comunicação em linha, tem poucas oportunidades de interação pessoal |

| Feiras de negócios: | Oportunidade de conhecer fornecedores pessoalmente, ver amostras de produtos em primeira mão, estabelecer contactos com profissionais do sector | Requer viagens, limitadas a períodos específicos do ano, podendo exigir um planeamento e despesas significativos |

| Agentes de aprovisionamento: | Experiência na navegação no mercado chinês, pode tratar do aprovisionamento e da logística, pode prestar assistência linguística | Custos adicionais, possibilidade de falhas de comunicação entre o cliente e o fornecedor, necessidade de uma análise cuidadosa para encontrar um agente com boa reputação |

Ventos favoráveis e mares revoltosos: Conclusão

Escolher o fornecedor certo de contraplacado marítimo é um investimento na longevidade e no sucesso do seu projeto. Ao considerar cuidadosamente as suas necessidades, efetuar uma pesquisa exaustiva e estabelecer uma parceria com um fornecedor de renome, pode navegar com confiança, sabendo que a sua obra-prima marítima é construída sobre uma base de qualidade e durabilidade.

Lembre-se, a viagem de mil milhas náuticas começa com uma única e bem escolhida folha de contraplacado marítimo. Escolha sabiamente e deixe que os seus sonhos náuticos ganhem forma!

Yuantuo Wood: O seu parceiro de confiança para ripas de cama de qualidade - Sourcing from China Made Easy

Procura ripas de cama fiáveis e de alta qualidade sem as dores de cabeça do sourcing? Não procure mais, Yuantuo Wood é a sua ligação direta às ripas de cama de primeira qualidade fabricadas na China.

Desde 2014, dedicamo-nos a fabricar ripas de cama duráveis e de suporte usando os melhores materiais e apoiados por certificações internacionais. Eis porque é que a Yuantuo Wood é o seu parceiro ideal para as ripas de cama:

Experiência e conhecimentos especializados

- Anos de excelência comprovada: Com quase uma década de experiência, aperfeiçoámos o nosso ofício, aperfeiçoando a arte do fabrico de ripas de cama para cumprir os mais elevados padrões da indústria.

- Qualidade sem compromissos: Acreditamos na construção para durar. As nossas ripas de cama são construídas com madeira de primeira qualidade proveniente de florestas geridas de forma responsável, garantindo durabilidade e desempenho duradouro.

- Certificações reconhecidas mundialmente: Fique descansado, a qualidade não é apenas uma promessa, é uma garantia. Possuímos certificações de prestígio, incluindo:

- FSC (Forest Stewardship Council): Garantir que a nossa madeira provém de florestas geridas de forma responsável, promovendo práticas florestais sustentáveis.

- EPA (Agência de Proteção do Ambiente): Cumprem as rigorosas normas americanas relativas à qualidade do ar e às emissões de formaldeído, garantindo um ambiente interior mais saudável.

- CARB (California Air Resources Board): Conformidade com os regulamentos rigorosos da Califórnia sobre emissões de formaldeído de produtos de madeira composta.

China Sourcing Made Simple

- Diretamente da fonte: Ao estabelecer uma parceria com a Yuantuo Wood, está a eliminar os intermediários e a abastecer-se diretamente no coração do fabrico de ripas de cama na China. Isto traduz-se em preços competitivos e maior controlo sobre a sua cadeia de fornecimento.

- Localização estratégica: A localização estratégica da nossa fábrica no condado de Wen'an, província de Hebei, oferece uma vantagem única:

- Excelente conetividade: Situada no cruzamento de Pequim, Tianjin e Hebei, desfrutamos de ligações de transporte perfeitas, garantindo uma entrega atempada no porto de Tianjin e não só.

- Logística eficiente: A nossa proximidade com os principais centros de transporte permite-nos otimizar a logística, reduzindo os prazos de entrega e garantindo que as suas ripas de cama chegam dentro do prazo.

O seu parceiro em conforto e qualidade

Na Yuantuo Wood, não nos limitamos a fornecer ripas de cama; proporcionamos paz de espírito. Seja nosso parceiro e experimente:

- Opções de personalização: Oferecemos uma gama de tamanhos, perfis e acabamentos de ripas de cama para satisfazer as suas necessidades específicas.

- Apoio ao cliente dedicado: A nossa equipa está empenhada em prestar um serviço excecional, orientando-o no processo de seleção e respondendo a quaisquer questões que possa ter.

Escolha a Yuantuo Wood para obter ripas de cama que combinam qualidade excecional, práticas sustentáveis e a conveniência de adquirir diretamente de um fabricante chinês de confiança. Contacte-nos hoje para discutir as suas necessidades de ripas de cama!

As 5 principais perguntas frequentes sobre o fornecimento de contraplacado marítimo da China

1. Que tipos de contraplacado marítimo estão facilmente disponíveis nos fornecedores chineses?

Os fornecedores chineses oferecem uma vasta seleção de contraplacado marítimo, satisfazendo diversas necessidades. Pode encontrar contraplacado fabricado a partir de várias espécies de madeira, como Okoume, Meranti e Bétula, cada uma com propriedades únicas. Quer necessite de tamanhos padrão ou cortes personalizados, diferentes espessuras ou acabamentos de superfície específicos, os fornecedores chineses podem satisfazer as suas necessidades.

2. Como posso garantir que a qualidade do contraplacado marítimo da China cumpre as normas do meu projeto?

Concentre-se em fornecedores com certificações reconhecidas internacionalmente, como a BS 1088 ou a conformidade com a Fase 2 do CARB. O pedido de amostras é crucial para avaliar fisicamente a qualidade do contraplacado, verificando se as superfícies são lisas, se os folheados do núcleo são consistentes e se a qualidade da ligação é forte. Não hesite em discutir os seus requisitos e expectativas de qualidade específicos com potenciais fornecedores.

3. Quais são os prazos de entrega típicos para encomendar contraplacado marítimo da China?

Os prazos de entrega variam em função de factores como o tamanho da encomenda, os requisitos de personalização e a capacidade de produção do fornecedor. É melhor comunicar o prazo de entrega pretendido com antecedência e informar-se sobre o prazo de entrega estimado pelo fornecedor para garantir que está de acordo com o calendário do seu projeto.

4. Quais são as condições de pagamento comuns quando se trabalha com fornecedores chineses de contraplacado marítimo?

As condições de pagamento são frequentemente negociáveis, mas normalmente envolvem uma combinação de um depósito inicial (por exemplo, 30%) e o saldo restante antes da expedição ou aquando da entrega. Discuta métodos de pagamento, segurança e quaisquer taxas ou impostos de importação aplicáveis com o fornecedor escolhido para estabelecer termos claros e mutuamente aceitáveis.

5. Como posso ultrapassar as barreiras linguísticas e assegurar uma comunicação eficaz com os fornecedores chineses?

Muitos fornecedores chineses são cada vez mais proficientes em inglês, especialmente os que lidam com clientes internacionais. Procure fornecedores com canais de comunicação dedicados, como representantes de vendas que falem inglês ou plataformas online com funcionalidades de tradução. Considere a possibilidade de utilizar uma linguagem clara e concisa, recursos visuais e ferramentas de tradução online para facilitar a comunicação.