In the world of construction, where strength and sustainability are paramount, FSC certified Laminated Veneer Lumber (LVL) has emerged as a game-changer. This engineered wood product, renowned for its exceptional strength, dimensional stability, and eco-friendly attributes, is revolutionizing the way we build, offering a responsible and reliable alternative to traditional lumber. This comprehensive guide delves deep into the world of FSC certified LVL, exploring its intricacies, applications, and the myriad benefits it brings to the table – ultimately highlighting why it’s become the material of choice for builders and architects committed to quality and sustainability.

Understanding FSC Certified LVL: What Sets it Apart?

LVL, in its essence, is a testament to the power of engineering ingenuity combined with nature’s resilience. It’s created by taking thin sheets of wood veneer and bonding them together with strong adhesives under heat and pressure, resulting in a product that surpasses the limitations of traditional lumber. What sets FSC certified LVL apart is the source of its wood and the rigorous standards it adheres to.

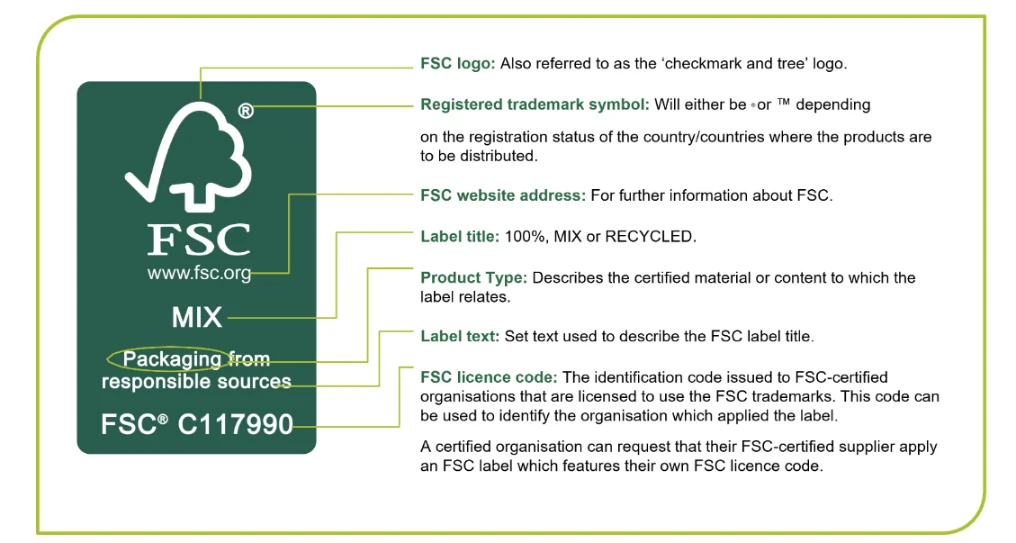

The FSC Difference: The Forest Stewardship Council (FSC) is a globally recognized organization dedicated to promoting responsible forest management. When you see the FSC logo on a product, it signifies that the wood used originates from forests that are managed in an environmentally responsible, socially beneficial, and economically viable manner. This means that the forests are managed in a way that preserves biological diversity, respects the rights of indigenous peoples, and ensures the long-term economic viability of the forest. Choosing FSC certified LVL is a conscious decision to support responsible forestry practices and contribute to a healthier planet.

Demystifying the Production Process: How FSC Certified LVL is Made

The journey from sustainably harvested logs to high-performance LVL beams involves a meticulous, multi-stage process:

- Sourcing from Responsible Forests: The process begins with sourcing wood from FSC-certified forests, ensuring that trees are harvested selectively and sustainably, minimizing environmental impact. This careful selection process ensures that the forests remain healthy and productive for generations to come.

- Veneer Production: Logs are peeled into thin sheets of veneer using specialized peeling machines. These veneers are then graded and sorted based on quality and grain orientation, ensuring that only the highest quality veneers are used in the production of LVL.

- Layering and Bonding: Veneer sheets are meticulously layered together with alternating grain directions. This cross-banding technique is crucial for enhancing strength and stability, as it distributes the load evenly and minimizes the risk of warping or twisting. A strong, moisture-resistant adhesive is applied between the layers, ensuring a permanent bond.

- Pressing and Curing: The layered veneer assembly is then pressed under high pressure and heat in a hydraulic press. This process activates the adhesive and bonds the layers together to form a solid, structural beam. The precise control of pressure and temperature is critical for achieving the desired strength and dimensional stability of the LVL.

- Cutting and Finishing: Once cured, the LVL beam is cut to specific dimensions using high-precision saws. The beams can also be further processed to create specific shapes or sizes, allowing for greater design flexibility. Finally, the LVL is finished to meet desired specifications, which may include sanding, priming, or treating for fire resistance.

Decoding the Specifications: Understanding FSC Certified LVL Properties

FSC certified LVL boasts an impressive array of properties that make it ideal for a wide range of structural applications, consistently outperforming traditional lumber in key areas:

| Property | Description |

|---|---|

| Strength and Stiffness | Exceptionally strong and stiff, often exceeding the strength-to-weight ratio of solid lumber. This exceptional strength makes LVL ideal for load-bearing applications. |

| Dimensional Stability | Highly resistant to warping, twisting, shrinking, and swelling, ensuring consistent performance over time. This stability is crucial for structural integrity and minimizes costly callbacks due to wood movement. |

| Availability in Long Lengths | Can be manufactured in long, continuous lengths, reducing the need for joints and simplifying installation. This allows for greater design flexibility and can speed up construction time. |

| Ease of Workability | Can be cut, drilled, and shaped using standard woodworking tools, making it easy to work with on the job site. |

| Fire Resistance | Treated LVL products can offer enhanced fire resistance, meeting stringent building codes and providing added safety. |

| Sustainability | Made from sustainably sourced wood, minimizing environmental impact and contributing to a healthier planet. |

Comparing the Contenders: FSC Certified LVL vs. Similar Products

| Feature | FSC Certified LVL | Solid Lumber | Steel Beams |

|---|---|---|---|

| Strength-to-Weight Ratio | High | Moderate | High |

| Dimensional Stability | Excellent | Low | Excellent |

| Sustainability | Excellent | Moderate | Low |

| Cost | Moderate | Low to High (depending on species and availability) | High |

| Ease of Installation | High | Moderate | Low |

| Fire Resistance | Moderate (can be treated) | Low | High |

Analysis: FSC certified LVL offers a compelling combination of strength, stability, sustainability, and ease of installation, making it a strong contender for a wide range of structural applications. While steel beams may offer comparable strength, LVL often surpasses steel in terms of sustainability, ease of installation, and cost-effectiveness.

Applications Abound: Where FSC Certified LVL Excels

The versatility of FSC certified LVL makes it an ideal choice for a wide range of applications, spanning residential, commercial, and industrial construction. Here’s a closer look at its key applications:

- Beams and Headers: LVL beams are exceptionally strong and dimensionally stable, making them ideal for supporting floors, roofs, and openings over doors and windows. Their ability to span long distances without sagging makes them particularly suitable for open-plan designs.

- Rim Boards and Wall Framing: LVL rim boards provide superior strength and stability to the perimeter of a structure, while LVL wall framing members offer a straight, true, and dimensionally stable framework for walls. They provide a solid nailing surface for sheathing and siding, ensuring a secure and long-lasting structure.

- Floor Joists and Trusses: LVL is increasingly used for floor joists and trusses, particularly in applications requiring long spans or heavy loads. Their high strength-to-weight ratio allows for greater design flexibility and can reduce the need for intermediate supports.

- Stair Stringers and Treads: LVL’s strength and dimensional stability make it an excellent choice for stair stringers and treads, ensuring a durable and reliable framework for staircases. LVL stairs are less likely to creak or sag over time, providing a solid and quiet walking surface.

- Window and Door Bucks: LVL provides a strong and stable frame for windows and doors, ensuring proper installation and long-term performance. Their dimensional stability helps prevent windows and doors from sticking or becoming difficult to operate due to wood movement.

Beyond these core applications, FSC certified LVL is also used in a variety of other applications, including:

- Scaffolding Planks

- Truck and Trailer Flooring

- Shipping Crates and Pallets

- Furniture Making

- Concrete Formwork

Who Benefits from FSC Certified LVL?

The advantages of FSC certified LVL extend to a wide range of stakeholders in the construction industry:

- Architects: LVL’s strength and dimensional stability allow architects to push design boundaries, creating innovative and aesthetically pleasing structures.

- Builders: LVL’s ease of installation, consistency, and long-term performance make it a reliable choice for builders, streamlining construction processes and minimizing callbacks.

- Homeowners: Choosing LVL for their homes provides homeowners with peace of mind, knowing that their homes are built with strong, durable, and sustainable materials.

Market Insights: Navigating the FSC Certified LVL Landscape

The demand for FSC certified LVL is on the rise, driven by a confluence of factors that highlight its relevance in a world increasingly focused on responsible building practices:

- Growing Awareness of Sustainability: The construction industry is increasingly embracing sustainable building practices, seeking materials with minimal environmental impact. FSC certified LVL aligns perfectly with this trend, offering a responsibly sourced and renewable alternative to traditional lumber.

- Demand for High-Performance Materials: As building codes evolve and architects push design boundaries, the exceptional strength and stability of LVL make it a sought-after material. Its ability to meet stringent performance requirements while offering design flexibility makes it a valuable asset in modern construction.

- Cost Competitiveness: While the initial cost of LVL may be higher than some traditional lumber options, its longevity, ease of installation, and reduced waste often result in overall cost savings. When factoring in the reduced labor costs, faster construction times, and minimized risk of callbacks, LVL often proves to be a more cost-effective solution in the long run.

Weighing the Pros and Cons: A Balanced Perspective

| Advantages | Limitations |

|---|---|

| Exceptional Strength and Stability: Outperforms traditional lumber in load-bearing applications, offering long-term reliability. | Can be more expensive than traditional lumber upfront. However, the long-term cost savings often outweigh the initial investment. |

| Sustainability: Sourced from responsibly managed forests, contributing to a healthier planet and meeting the growing demand for eco-friendly building materials. | Requires proper handling and storage to prevent moisture damage. Proper acclimation and protection from the elements are crucial for maintaining its performance. |

| Design Versatility: Available in long lengths and various sizes, offering design flexibility for architects and builders. | Limited availability of complex shapes and sizes compared to steel. However, advancements in LVL technology are expanding its design possibilities. |

| Ease of Installation: Lightweight and easy to work with, reducing labor costs and speeding up construction time. |

Sourcing Your Materials: Comparing FSC Certified LVL Suppliers

| Supplier | Location | Price Range (per cubic meter) | Specialties |

|---|---|---|---|

| Weyerhaeuser | United States | $800 – $1,200 | Wide range of LVL products, including beams, headers, and rim board, known for their commitment to quality and innovation. |

| Georgia-Pacific | United States | $750 – $1,100 | Focus on sustainable forestry practices, known for quality LVL products and a commitment to responsible sourcing. |

| Roseburg | United States | $850 – $1,250 | Offers specialty LVL products, including fire-retardant options, catering to projects with specific performance requirements. |

| Yuantuo Wood | China | $700 – $1,000 | Large-scale LVL manufacturer with a global reach, known for competitive pricing and a wide distribution network. |

Note: Prices are approximate and can vary depending on factors such as quantity, location, and market conditions. It’s always recommended to contact suppliers directly for current pricing and availability.

Frequently Asked Questions: Addressing Your Queries

1. What is the typical lifespan of FSC certified LVL?

With proper installation and maintenance, FSC certified LVL can last for decades, offering exceptional durability and longevity. Its resistance to moisture, insects, and decay contributes to its long lifespan, making it a wise investment for long-term projects.

2. Can FSC certified LVL be used in exterior applications?

While LVL is generally intended for interior use, there are treated LVL products specifically designed for exterior applications, offering enhanced moisture resistance. These treated products are suitable for applications such as exterior trim, soffits, and fascia.

3. How do I ensure the authenticity of FSC certification?

Look for the FSC logo and license code on LVL products. You can also verify the certification status of suppliers on the FSC website, ensuring that the products you’re purchasing meet the highest standards of responsible forestry.

4. What are the fire safety considerations for using LVL?

While LVL is generally considered to have moderate fire resistance, there are fire-retardant treated LVL products available for applications requiring enhanced fire safety. These treated products are often required in commercial buildings and multi-family dwellings to meet building codes.

5. How does the cost of FSC certified LVL compare to traditional lumber?

While the initial cost of LVL may be higher, its longevity, ease of installation, and reduced waste often result in overall cost savings over the lifespan of a project. When factoring in reduced labor costs, faster construction times, and the minimized risk of callbacks, LVL often proves to be a more cost-effective solution in the long run.

Why Choose Yuantuo Wood for Your FSC Certified LVL Needs?

As you’ve read, FSC certified LVL offers a unique blend of strength, sustainability, and versatility, making it the ideal choice for a wide range of construction projects. When sourcing this exceptional material, choosing the right supplier is paramount. Yuantuo Wood, with our unwavering commitment to quality, sustainability, and customer satisfaction, is your trusted partner for all your FSC certified LVL needs.

Here’s why you should choose Yuantuo Wood:

- Uncompromising Commitment to Sustainability: At Yuantuo Wood, we share your passion for responsible forestry. Our FSC certification is a testament to our dedication to sourcing wood from sustainably managed forests, ensuring that your projects contribute to a healthier planet.

- Experience and Expertise: With years of experience in the wood industry, we have developed a deep understanding of the unique properties and applications of LVL. Our team of experts is here to guide you through every step of the process, from product selection to technical support.

- Strategic Location and Efficient Logistics: Located in close proximity to major transportation hubs, we ensure timely and efficient delivery of your LVL orders, keeping your projects on schedule and within budget.

- Focus on Quality and Innovation: We are committed to delivering LVL products that meet the highest standards of quality and performance. Our state-of-the-art manufacturing facilities and rigorous quality control processes ensure that you receive products that exceed your expectations.

- Customer-Centric Approach: At Yuantuo Wood, our customers are at the heart of everything we do. We strive to build long-term partnerships based on trust, transparency, and exceptional service.

Partner with Yuantuo Wood and experience the difference of working with a supplier who shares your commitment to quality, sustainability, and excellence.

Conclusion: Embracing a Sustainable Future with FSC Certified LVL

As the construction industry navigates the demands of a rapidly changing world, FSC certified LVL stands out as a beacon of sustainability and innovation. Its exceptional strength, dimensional stability, and eco-friendly attributes make it a compelling choice for builders, architects, and anyone seeking to create structures that are as good for the planet as they are for the people who inhabit them. By choosing FSC certified LVL, you’re not just building structures; you’re investing in a greener, more sustainable future for generations to come.