スラットは、数え切れないほど多くの用途で目にすることのないヒーローであり、安眠から家の構造的完全性まで、あらゆるものの重要な土台となっています。スラットの重要性は、サポート力、安定性、長寿命を提供する能力にありますが、スラットの世界をナビゲートするのは、さまざまな種類があるため大変です。この包括的なガイドでは、人気のある3種類のスラットのユニークな特徴を掘り下げています: 合板スラット、LVLスラット、ベッド用スラット.スラットの製造工程、利点、制限、理想的な使用例を理解することで、特定のニーズに適したスラットタイプを自信を持って選択することができます。

合板スラット汎用性と強度を兼ね備えたシート

合板エンジニアリング・ウッドの可能性は、建築や家具作りに革命をもたらしました。その強度対重量比と卓越した汎用性により、合板はさまざまなプロジェクトに最適な素材となっています。特に合板スラットは、過度な重量を加えることなく、確実なサポートと安定性を提供する能力で支持されています。しかし、この汎用性の高い積み木は、一体どのようにして作られるのでしょうか?

合板スラットの製作層のシンフォニー

合板の魔法は、その層構造にある。プライと呼ばれる単板の薄いシートは、木目の方向が90度の角度で交互になるように注意深く積み重ねられます。この戦略的な積み重ねが、熱と圧力の下、強力な接着剤で接着され、合板の驚異的な強度と寸法安定性の鍵となっています。クロスグレイン技術は、パネル全体に効果的に応力を分散させるため、大きな荷重がかかっても曲げや反り、割れに驚くほど強くなります。

合板スラットの種類:選択肢を探る

すべての合板スラットは共通の層構造を持つが、さまざまなタイプがあり、それぞれが特定の用途や環境に合わせて調整されている:

- サンディングされた合板: このタイプは表面が滑らかでサンディングされ ているのが特徴で、家具作りや棚板、装飾用途な ど、外観が重要なプロジェクトに適しています。さまざまな等級があり、等級が高いほど、より滑らかで傷のない表面を提供します。

- シージング合板: 壁下地、屋根下地、床下地などの構造用途に設計された合板で、強度と剛性を優先しています。通常、サンディング合板よりも粗く、さまざまな気象条件への適合性を示す暴露等級が表示されていることが多い。

- 耐湿合板: このタイプは、耐水性の接着剤と樹脂で処理されており、湿気や時折の水濡れに耐える。キッチンや浴室、外壁の下地やサイディングなどによく使われる。

- 海洋合板: 耐湿性の金字塔である船舶用合板は、防水接着剤と欠陥のない最高級単板を使用しています。ボート建造やドックなど、卓越した耐水性が求められる用途に最適です。

- 耐火合板: 難燃化学薬品で処理されたこのタイプの合板は、炎や煙の広がりを遅らせ、火災の安全性を高めます。商業ビルやマンションなど、消防法の厳しい地域でよく使われる。

適切な合板スラットタイプの選択は、耐荷重、湿気暴露、防火規制、美的嗜好などの要素を考慮し、プロジェクト特有の要件によって決まります。

合板スラットの利点:

- 卓越した強度と安定性: 合板の層構造は、クロスグレイン技術によって強化され、非常に強く、反り、曲げ、ひび割れに対して耐性があります。そのため、床下地、壁下地、頑丈な棚など、構造的な完全性が最も重要な用途に最適です。

- 軽量でありながら耐久性がある: 合板はその優れた強度にもかかわらず、驚くほど軽量で、取り扱いや運搬、施工が容易です。この強度と軽さのユニークな組み合わせにより、屋根裏の床材や移動式住宅の建設など、重量が懸念されるプロジェクトでは実用的な選択肢となります。

- 幅広い厚みとサイズ: 合板スラットは、多様なプロジェクト要件に対応するため、豊富な厚みとサイズを取り揃えています。この多様性により、カスタマイズが可能になり、軽荷重の棚や重荷重の建設用途など、お客様の特定のニーズに完璧に適合するものを確実に見つけることができます。

- 費用対効果の高いソリューション: 合板は一般的に、無垢材と比較して予算に見合った価格を誇り、大規模なプロジェクトや予算を重視する人にとって魅力的な選択肢となります。この手頃な価格と印象的な性能が相まって、合板は住宅と商業建築の両方で人気のある選択肢となっています。

- 滑らかで一貫性のある表面: 合板は層構造になっているため、表面は平滑で一定しており、さまざまな仕上げを容易に受け入れることができます。塗装、染色、ラミネート加工が簡単にできるため、デザインの可能性が無限に広がり、家具やキャビネット、壁の化粧板など、美観が重視される用途に適しています。

合板スラットの限界:

- 湿気の影響を受けやすい: 合板は耐湿性を考慮して設計されていますが、水や高湿度に長時間さらされると、構造上の完全性が損なわれます。層が剥離したり、接着剤の結合が弱くなり、反りや膨張の原因となります。適切なシーリングと保護は、特に外装用途や浴室やキッチンのような高湿度環境では不可欠です。

- 目に見えるエッジは仕上げが必要: 合板スラットの積層エッジはしばしば露出するため、磨き上げられた美的外観を得るためには、エッジバンディングやその他の仕上げ技術が必要となります。これは、製造工程に余分なステップとコストを加えることになり、端が見えるプロジェクトでは重要な考慮事項となります。

- LVLほどの寸法安定性はない: 合板の安定性は称賛に値しますが、極端な湿度の変化により、わずかな寸法変化の影響を受けることがあります。そのため、LVLに比べて寸法安定性が低く、特にドアや窓枠のように絶対的な精度が要求される用途では、わずかな反りでも機能性に支障をきたす可能性があります。

LVLスラット究極の強度と安定性を実現

集成単板製材(LVL)は、エンジニアード・ウッドの能力を示す輝かしい例であり、強度と安定性をまったく新しいレベルに引き上げています。その製造工程により、ある面では無垢材をも凌駕する製品を生み出し、要求の厳しい構造用途の最良の選択肢となっています。LVLスラットは、その卓越した強度、驚異的なスパン能力、優れた寸法安定性で有名で、現代の建築には欠かせないものとなっています。

LVLスラットの製造数の力

LVLスラットは、合板に似た単板の薄いシートから作られますが、決定的に異なるのは、すべての単板が同じ方向に向いており、その軸に沿った木材固有の強度が最大化されていることです。これらの単板を、非常に強力で耐湿性のある接着剤を使い、莫大な圧力と熱の下で貼り合わせる。この工程を経ることで、大きく頑丈で、非常に強靭な梁が生まれ、卓越した構造的完全性を発揮するのです。

LVLスラットの利点

- 比類のない強度とスパン能力: LVLスラットは、その卓越した強度で有名で、特に曲げ耐性に関しては、従来の木材を上回ることがよくあります。この驚異的な強さにより、中間サポートを必要とせず、より長い距離を支えることができるため、広いオープンスペースや、屋根や床を支えるような頑丈な用途に理想的です。

- 優れた寸法安定性: 時の試練と様々な環境条件に耐えるよう設計されたLVLスラットは、湿度の変動による収縮、膨張、反りに対して非常に耐性があります。この優れた寸法安定性により、ドアや窓枠のように、わずかな反りでも機能性に影響を与えかねない、精度と一貫性が最も重要な用途に適しています。

- 一貫した品質とパフォーマンス: LVLの製造工程では、天然材では困難な、品質と一貫性の高度な管理が可能です。各スラットは特定の性能基準を満たすように設計され、建築基準法や安全規制を満たすために重要な構造用途における信頼性と予測可能性を保証します。

- ロング・レングスが入手可能: LVLスラットは、従来の製材に比べかなり長い長さで製造できるため、継ぎ目の必要性が減り、より強く安定した構造体を作ることができます。これは、オープン・コンセプトの設計や広大な商業ビルなど、大スパンの用途や中断のないスパンを必要とするプロジェクトに特に有利です。

- 環境に優しいオプション: LVLの生産は、より小さく、より早く成長する樹木を利用するため、より大きく、原生林に依存することが多い従来の製材に比べ、より持続可能で環境に配慮した選択肢となる。このような資源の効率的な利用は、環境に配慮した建築慣行と一致し、建築による環境への全体的な影響を軽減するのに役立ちます。

LVLスラットの限界:

- 合板より高い: LVLの優れた強度、安定性、予測可能性には代償が伴います。LVLスラットは一般的に合板スラットより高価であり、プレミアムオプションとなります。しかし、そのコスト差は、その卓越した性能、長寿命、廃棄物の削減によって正当化されることが多く、特に、失敗が許されない要求の厳しい構造用途では、その差が顕著です。

- 限られた審美的オプション: LVLスラットは、主にその構造的特性のために設計されており、その外観はこの実用的な目的を反映しています。LVLスラットは、天然木のような美的魅力に欠けるため、むき出しの梁や家具のデザインなど、美観を重視する用途には適していません。

- 専用の切削工具が必要: LVLは密度が高く硬いため、特殊な切削工具や技術を必要とし、合板や従来の木材に比べて加工が難しい。そのため、プロジェクトによっては特殊な設備や専門の施工業者が必要になることも少なくありません。

もっと見る LVLスラット タイプだ:LVLスラットより良い家づくりの秘訣

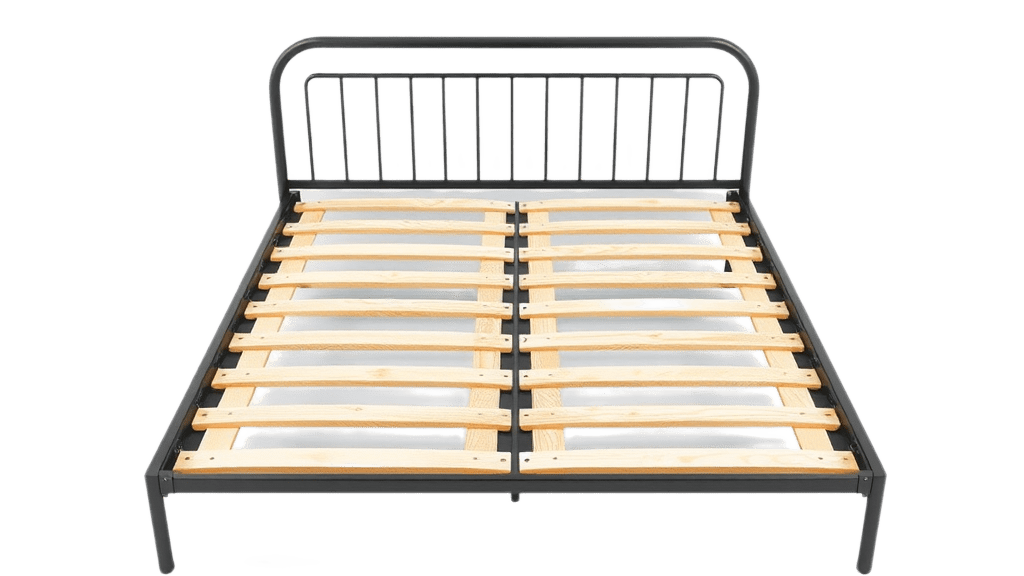

ベッドのスラット快眠の基礎

合板やLVLスラットが建築の主役になることが多い一方で、ベッドスラットは私たちの生活により密接な役割を果たし、快適でサポート力のある睡眠を静かに保証します。見過ごされがちなこの部品は、マットレスとベッドフレームをつなぐ重要な役割を果たし、マットレスの寿命だけでなく、睡眠の質にも影響を与えます。ベッドスラットの種類とそれぞれの特徴を理解することは、新しいベッドフレームを選ぶ際や、既存のベッドフレームをアップグレードする際に、十分な情報を得た上での決断に役立ちます。

ベッドのスラットの種類多様な風景

ベッド用スラットにはさまざまな素材があり、それぞれ柔軟性、サポート力、価格帯が独自にブレンドされています。適切な素材を選ぶには、多くの場合、個人の好み、希望の硬さレベル、予算によります:

- 木製ベッド・スラット: 永遠の定番である木は、強度、柔軟性、自然な魅力のバランスが取れたベッド用スラットとして、依然として人気の高い選択肢です。木製のスラットは、サポート力と適度なゆとりの両方を提供し、身体のラインにフィットして快適性を高めることができるため、好まれています。

- ブナ: 強度と耐久性に優れ、わずかにたわむことで知られるブナは、優れたサポート力とマットレスの通気性を促進します。高級ベッドフレームによく使われ、硬さと柔軟性のバランスを求める方に適しています。

- 松だ: 手頃な価格のパイン材は、適度なサポート力と自然な外観を備えていますが、ブナなどの広葉樹に比べると耐久性に劣ります。予算重視の消費者や、より軽量なものを求める人には良い選択肢です。

- バーチだ: 強度と柔軟性のバランスが取れたバーチ材は、サポート力と手頃な価格のバランスが取れた素材です。さまざまな寝心地とマットレスのタイプに対応する、汎用性の高いオプションです。

- 金属製ベッド・スラット 金属製ベッドスラットは一般的にスチール製で、マットレスの土台として頑丈で耐久性があります。強度が高く、重い荷重にも耐えることができるため、体重の重い方や硬めの寝心地を求める方に適しています。ただし、木製スラットに比べると柔軟性に欠け、寝心地や通気性が劣る場合があります。

- プラスチック製ベッド用スラット: あまり一般的ではありませんが、プラスチック製ベッド用スラットは軽量で手頃なオプションです。しかし、木製や金属製のスラットと同レベルのサポートや耐久性を提供できない場合があり、一般的に長期的な使用にはあまり望ましくない選択肢と考えられています。ゲスト用ベッドや子供用ベッドなど、一時的な用途や軽負荷の用途には適しているかもしれません。

その他の木製ベッド用スラット

ベッドのスラットを選ぶ際に考慮すべき要素:

- スラットの間隔: スラットの間隔は、サポートと硬さのレベルを決める重要な役割を果たします。間隔が狭い(2~3インチ)ほど、しっかりとしたサポートが得られ、体重の重い方や硬めの寝心地を好む方、メモリーフォームマットレスなど、よりサポートが必要なマットレスをお使いの方におすすめです。間隔を広く(4~5インチ)すると、柔軟性と通気性が増し、体重の軽い方やソフトな感触を好む方、ラテックスマットレスのように通気性を高めるマットレスをお使いの方に適しています。

- スラット幅: スラットの幅もサポート力と耐久性に影響します。スラットの幅が広いほど、体重を分散する表面積が大きくなり、サポート力が高まり、マットレスのヘタリを防ぎます。一般的に、体重の重い方や、マットレスのサポート力と耐久性を最大限に高めたい方には、幅の広いスラットが好まれます。

- マットレスタイプ メモリーフォーム、インナースプリング、ラテックスなど、マットレスのタイプによって、必要なサポート力や通気性は異なります。メモリーフォームマットレスはスラットの間隔を狭くした方が最適なサポートが得られることが多く、ラテックスマットレスは間隔を広くした方が通気性が良くなることがあります。

- 個人的な好み: 結局のところ、最適なベッドスラットはあなたにとって一番しっくりくるものです。自分の睡眠の好み、体型、マットレスのタイプなどを考慮して決めましょう。また、可能であればさまざまなタイプのスラットを試してみて、それぞれのニーズに合った寝心地とサポートの完璧なバランスを見つけるのもよいでしょう。

スラット・タイプに関するよくある質問

1.合板スラットは、根太のような構造用途に使用できますか?

合板は強度が高く、下地や床下地など様々な用途に使用できますが、床根太のような重要な構造部材にはお勧めできません。これらの部材には、LVLのようなエンジニアード・ランバーが提供する卓越した強度、スパン能力、寸法安定性が必要です。このような状況で合板を使用すると、たるみや不安定さを招き、構造的な欠陥につながる可能性があります。

2.どのようなベッドスラットがメモリーフォームマットレスに最適ですか?

身体にフィットすることで知られるメモリーフォームマットレスは、ヘタリを防ぎ、適切な体重配分を確保するために、スラットの間隔を詰める必要があります(理想は2~3インチ)。ブナやカバなどの丈夫な広葉樹のスラットを選ぶと、強度、柔軟性、耐久性のバランスが取れます。間隔が広いと、サポートにムラができたり、マットレスが早くへたったりする可能性があるため避けましょう。

3.合板スラットを湿気から守るには?

合板のアキレス腱は湿気に弱いことで、特に長時間湿気にさらされるとダメージを受けます。合板のスラットを保護するには、高品質のシーラントをすべての表面に塗布し、湿気が浸透しやすい端や切り口に細心の注意を払いましょう。バスルームやエクステリアなど湿気の多い場所では、合板と潜在的な水源との間に耐湿性のバリアを追加することを検討してください。

4.LVLスラットは従来の木材よりも環境に優しいのですか?

そう、LVLは一般的に、従来の製材に比べて環境面で優れている。LVLの製造工程では、より小さく、より早く成長する木を利用することで、資源効率を最大化し、原生林への依存を最小限に抑えます。このような責任ある調達とLVLの耐久性と長寿命が相まって、環境意識の高い建築業者にとってより持続可能な選択肢となっています。

5.LVLスラットを塗装したり、汚したりすることはできますか?

技術的には可能ですが、LVLスラットの塗装や染色は一般的に推奨されません。LVLは主に構造用として設計されており、その表面は美的仕上げ用に設計されていません。また、LVL製造時に使用される処理薬品は、塗料の接着を妨げ、不均一な仕上げや剥離の可能性につながります。特殊な美観が必要な場合は、建築の専門家にご相談の上、適切な代替品やカバーリングをお選びください。

結論適材適所のスラット

スラットの世界に圧倒される必要はありません。さまざまなスラットタイプの特徴、利点、制限を理解することで、特定のニーズに最適なオプションを自信を持って選択することができます。大規模な建設プロジェクトに着手する場合でも、家具を製作する場合でも、単に安眠のためにより支持力のある土台を求める場合でも、適切なスラットを選択することで、性能、耐久性、全体的な満足度に大きな違いが生まれます。