In the world of construction and furniture making, stability is non-negotiable. Whether you’re building a sturdy roof, crafting a reliable bookshelf, or ensuring a bed frame can withstand years of late-night reading, the materials you choose matter. That’s where LVL slats come in – engineered for strength, consistency, and versatility. But with various options available, how do you navigate the world of LVL and select the perfect slats for your project?

This comprehensive guide is designed to equip builders, contractors, DIY enthusiasts, and anyone involved in projects demanding structural integrity with the knowledge to confidently choose the right LVL slats, ensuring project success and long-lasting durability.

What Exactly are LVL Slats, and Why Should You Care?

LVL stands for Laminated Veneer Lumber, and it’s a type of engineered wood product that’s rapidly gaining popularity across a multitude of industries – and for good reason. Here’s a closer look at what makes LVL slats a game-changer:

- Engineered for Strength: LVL slats are created through a specialized manufacturing process that involves layering thin sheets of wood veneer together with strong, moisture-resistant adhesives. This cross-grain layering technique, where the grain of each veneer layer runs perpendicular to the adjacent layers, creates a solid, consistent material that’s significantly stronger and more dimensionally stable than traditional lumber, particularly when subjected to bending or weight-bearing forces.

- Consistent Performance, Predictable Results: One of the primary advantages of LVL slats over traditional lumber lies in their remarkable consistency. Unlike solid wood, which can warp, twist, or bow over time due to variations in grain structure and moisture content, LVL slats are engineered for uniformity. This predictability ensures consistent performance across the board, making them a reliable choice for projects where precision and structural integrity are paramount.

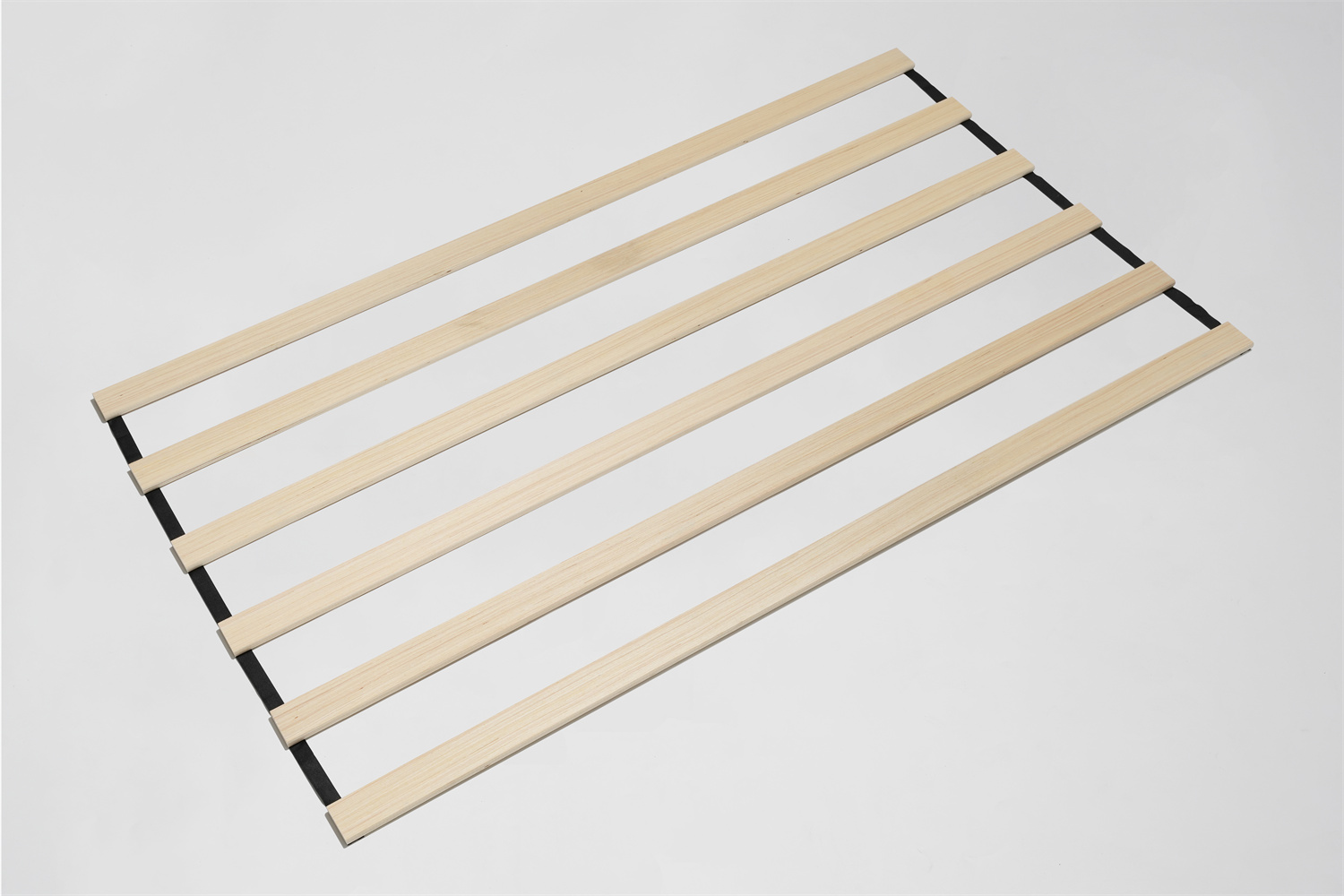

- Versatility That Knows No Bounds: The applications for LVL slats are as diverse as the projects they support. From heavy-duty structural components like beams, headers, and joists in residential, commercial, and industrial buildings, to lighter-duty applications in furniture making, shelving, door cores, and even marine construction, LVL slats offer a remarkable range of possibilities. Their adaptability to various project scales and design requirements makes them an invaluable asset in the construction and manufacturing industries.

Decoding the LVL Lingo: Key Terms to Know

Before we delve into the selection process, let’s equip ourselves with a basic understanding of common LVL terminology. This will not only help you decipher product specifications but also facilitate more effective communication with suppliers and contractors:

- Span: In the simplest terms, span refers to the distance a beam or slat can safely support a load without excessive bending or deflection. Think of it as the unsupported distance between two points that the LVL slat will bridge. For instance, in a roof structure, the span of a beam would be the distance between the supporting walls.

- Load: Load refers to the weight or force applied to a structural element, such as a beam or slat. This could include the weight of the structure itself (dead load), as well as any additional weight it’s designed to support, such as furniture, occupants, or environmental factors like snow or wind (live load). Accurately calculating loads is crucial for selecting LVL slats with sufficient strength.

- Moisture Content: The moisture content of wood, including LVL slats, is a critical factor influencing its stability. It’s expressed as a percentage of the wood’s dry weight. Lower moisture content generally translates to greater dimensional stability, meaning the wood is less likely to shrink, warp, or twist over time. Kiln-dried LVL slats typically have a moisture content of 10-12%.

- Grade: LVL slats, like many building materials, are categorized into different grades based on their strength and stiffness properties. Higher grades indicate greater load-bearing capacity and are typically used for more demanding structural applications. The grading system ensures that the LVL slats you choose meet the specific performance requirements of your project.

- Treatment: To enhance their resistance to moisture, insects, and decay, LVL slats can be treated with preservatives. These treatments can vary depending on the intended application and the environmental conditions the slats will be exposed to. For example, slats used in exterior applications or areas with high humidity are typically treated with water-resistant preservatives.

Navigating the Selection Process: 5 Factors to Consider

Choosing the right LVL slats isn’t a one-size-fits-all endeavor. It requires careful consideration of your project’s specific requirements and the demands placed upon the material. Here’s a step-by-step guide to help you make informed decisions:

1. Define Your Project Scope and Requirements:

Before diving into the technical specifications of LVL slats, take a step back and clearly define your project’s scope and the specific demands placed upon the material. Ask yourself these key questions:

- What is the intended application of the LVL slats? Are they for structural support, such as beams, headers, joists, or roof trusses, or non-structural applications like furniture components, shelving, decorative trim, or packaging materials?

- What are the load-bearing requirements? How much weight will the slats need to support? This includes both dead loads (the weight of the structure itself) and live loads (any additional weight the structure is designed to bear). Accurate load calculations are crucial for selecting LVL slats with adequate strength.

- What is the required span? What is the distance the slats need to bridge without intermediate support? This factor is crucial for determining the required strength and stiffness of the LVL slats. Longer spans generally require thicker and/or wider slats to prevent excessive deflection.

- What are the environmental conditions? Will the slats be exposed to moisture, humidity, or extreme temperatures? Understanding the environmental factors at play will help you select slats with the appropriate treatment and moisture content. For instance, exterior applications may require slats treated for water resistance and UV protection.

2. Determine the Appropriate LVL Grade:

LVL slats are available in various grades, each engineered to meet specific performance requirements. The most common grades include:

- Standard Grade: Suitable for general construction and non-structural applications where high strength is not critical. This grade is often used for shorter spans, lighter loads, and components that are not primary structural elements. Typical applications include shelving, furniture components, and short-span headers.

- Architectural Grade: Offers enhanced strength and stiffness compared to standard grade, making it suitable for longer spans and heavier loads. This grade is commonly used for beams, headers, joists, and roof trusses in residential and light commercial construction. It’s also a popular choice for demanding furniture applications, such as heavy-duty tabletops and shelving units.

- Prime Grade: The highest grade of LVL slats, providing exceptional strength and stability for demanding structural applications. This grade is often specified for projects requiring long, unsupported spans, heavy load-bearing capacities, and resistance to extreme environmental conditions. Prime grade LVL is frequently used in bridge construction, heavy timber framing, and industrial applications.

Consulting with a structural engineer or building professional is highly recommended to determine the appropriate LVL grade for your project’s specific load-bearing requirements and safety considerations. They can perform detailed calculations and consider factors like building codes and local regulations to ensure the chosen grade meets the necessary standards.

3. Calculate the Required Dimensions:

The dimensions of your LVL slats, including thickness, width, and length, will directly impact their load-bearing capacity, span capabilities, and overall performance.

- Thickness: Thicker slats generally offer greater strength and stiffness, allowing them to support heavier loads and span greater distances without excessive deflection. The required thickness will depend on the load, span, and the spacing between the slats.

- Width: Wider slats provide more surface area for bonding between the veneer layers, which can contribute to increased strength and load-bearing capacity. Wider slats are often used for beams and headers, while narrower slats are suitable for applications like shelving and furniture components.

- Length: Longer slats can span greater distances but may require additional support depending on the load and the structural design. Longer slats are available but may require special handling and transportation considerations.

It’s essential to refer to manufacturer’s span tables or consult with a structural engineer to determine the appropriate dimensions for your project, ensuring that the chosen slats meet the required safety and performance standards. These resources provide detailed information on the load-bearing capacities and span limitations of different LVL slat sizes and grades.

4. Consider Moisture Content and Treatment:

The moisture content of LVL slats can significantly impact their dimensional stability and long-term performance. Slats with higher moisture content are more susceptible to shrinking, warping, or twisting as they dry, which can compromise the structural integrity of your project.

- Choose kiln-dried slats: Kiln drying is a controlled drying process that removes excess moisture from the wood, ensuring greater stability and minimizing the risk of movement over time. Kiln-dried LVL slats are the industry standard for most construction and furniture-making applications.

- Consider treated slats for exterior applications or humid environments: Treated LVL slats are impregnated with preservatives that protect them against moisture damage, decay, and insect infestation. This makes them suitable for outdoor projects, areas with high humidity, or applications where the slats will be exposed to moisture. Common treatments include water-resistant preservatives, fire retardants, and insecticides.

5. Explore Additional Features and Options:

LVL slat manufacturers often offer additional features and options to enhance their functionality, simplify installation, and meet specific project requirements. These may include:

- Finger-jointed edges: Finger-jointing is a technique that involves interlocking the ends of veneer sheets during the manufacturing process. This creates longer, more stable slats with increased strength and reduced waste compared to traditional butt-jointed slats. Finger-jointing is particularly beneficial for applications requiring long, continuous spans.

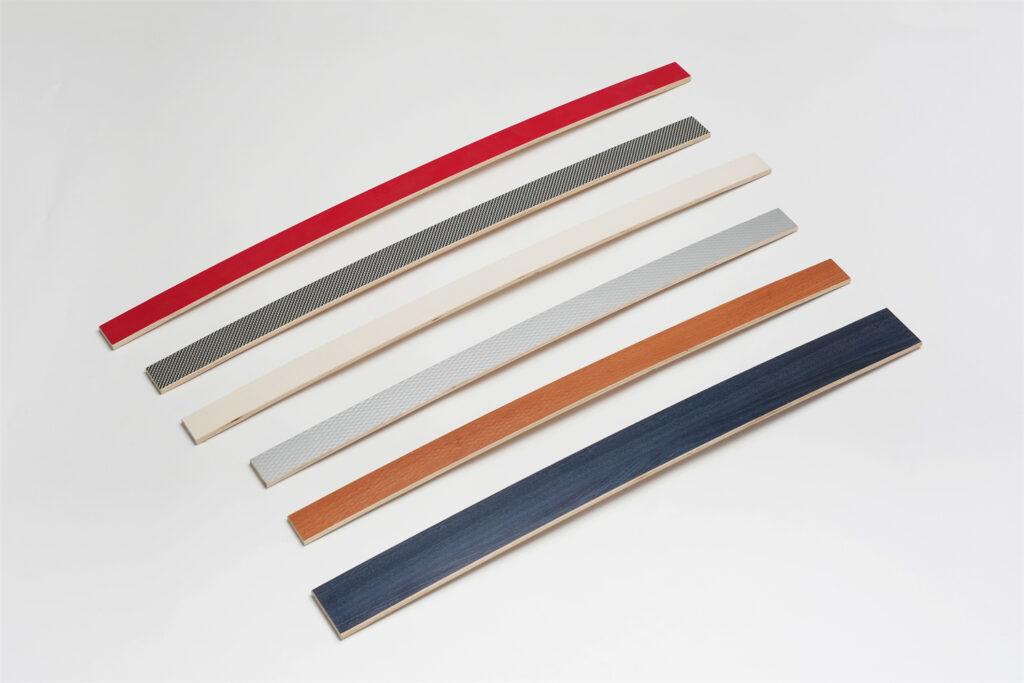

- Pre-primed or pre-finished options: Some manufacturers offer LVL slats that are pre-primed or pre-finished, saving time and labor during installation and finishing. This can be particularly beneficial for projects with tight deadlines or where on-site finishing is not feasible. Pre-finished options may include stain, paint, or protective coatings.

- Custom sizing and cutting: For unique project requirements or to minimize waste, some manufacturers provide custom sizing and cutting services. This allows you to order LVL slats tailored to your exact specifications, ensuring a perfect fit and streamlined installation. Custom sizing and cutting can be particularly valuable for complex projects or when working with limited space.

Making Informed Decisions: LVL Slat Comparison Table

To further aid your decision-making process, here’s a comparison table highlighting the key characteristics of different LVL slat grades:

| Grade | Strength & Stiffness | Typical Applications | Moisture Content | Treatment Options |

|---|---|---|---|---|

| Standard Grade | Good | General construction, non-structural framing, shelving, furniture components, interior trim, stair stringers, bracing elements. Suitable for shorter spans, lighter loads, and applications where high strength is not the primary consideration. | Kiln-dried | Untreated, treated for exterior or interior use. Untreated slats are suitable for interior applications in dry conditions. Treated slats offer enhanced protection against moisture, insects, and decay. |

| Architectural Grade | Better | Longer spans, heavier loads, beams, headers, joists, roof trusses, window and door headers, ridge beams, scaffold planks, framing for decks and porches. Commonly used in residential and light commercial construction, as well as demanding furniture. | Kiln-dried | Treated for exterior or interior use. Treatment options may include water-resistant preservatives, fire retardants, and insecticides, depending on the intended application and local building codes. |

| Prime Grade | Best | Demanding structural applications, long spans, heavy loads, beams, headers, support columns, bridge construction, heavy timber framing, industrial applications requiring high strength and dimensional stability. Often specified for critical structures. | Kiln-dried | Treated for exterior or interior use. Prime grade LVL slats are typically treated with high-performance preservatives to ensure long-term durability and resistance to extreme environmental conditions and heavy use. |

Beyond Strength: The Advantages of Choosing LVL Slats

Choosing LVL slats for your next project offers a multitude of advantages beyond their exceptional strength and stability:

- Cost-Effectiveness: While the initial cost of LVL slats might be slightly higher than traditional lumber, their longevity, reduced waste, and ease of installation often result in overall cost savings over the life of the project. LVL’s dimensional stability reduces the likelihood of warping, twisting, or bowing, minimizing the need for costly repairs or replacements.

- Sustainability: LVL slats are typically manufactured using fast-growing, sustainably harvested wood species, making them an environmentally responsible choice. The use of veneers allows manufacturers to maximize the yield from each log, minimizing waste and reducing the environmental impact of harvesting. Additionally, the long lifespan of LVL contributes to its sustainability by reducing the need for frequent replacements.

- Ease of Installation: Their consistent dimensions, lightweight nature, and availability in longer lengths make LVL slats easier to handle and install than traditional lumber. This can significantly reduce labor costs and speed up construction timelines. Their predictability simplifies the construction process, as builders can rely on consistent dimensions and performance.

- Design Flexibility: LVL slats can be cut, shaped, and finished to meet a wide range of design aesthetics, making them suitable for both modern and traditional projects. They can be stained, painted, or left natural to complement various architectural styles. Their versatility allows architects and designers to incorporate them into a variety of applications, from exposed beams and trusses to sleek furniture pieces.

Building with Confidence: Ensuring Project Success

By understanding the factors involved in choosing the right LVL slats, you’re empowered to make informed decisions that contribute to the long-term success of your projects. Remember to:

- Consult with professionals: For structural applications, always consult with a qualified structural engineer or building professional to determine the appropriate LVL grade, dimensions, and installation methods. Their expertise is essential for ensuring the safety and structural integrity of your project. They can assess the specific requirements of your project, taking into account factors like load calculations, span limitations, and local building codes.

- Source from reputable suppliers: Choose LVL slat suppliers with a proven track record of quality and reliability. Look for suppliers who adhere to industry standards, provide detailed product information, and offer excellent customer support. A reputable supplier will be able to answer your questions, provide technical guidance, and ensure you receive the right products for your project.

- Follow manufacturer’s guidelines: Adhere to the manufacturer’s recommendations for installation, handling, and finishing to ensure optimal performance and longevity of your LVL slats. This includes using the appropriate fasteners, adhesives, and protective coatings. Following these guidelines will help you maximize the lifespan of your LVL slats and prevent potential issues down the road.

With the right knowledge and careful planning, LVL slats can become your secret weapon for achieving unmatched stability, durability, and design versatility in your next construction or furniture-making endeavor.

Your Top LVL Slat Questions Answered

1. Can I use LVL slats for exterior applications like decks or pergolas?

Absolutely! LVL slats are available with treatments specifically designed for exterior use. These treatments protect the wood from moisture damage, decay, and insect infestation, ensuring long-lasting performance in outdoor environments. When choosing LVL for exterior projects, look for slats treated with water-resistant preservatives and UV inhibitors to prevent fading from sunlight exposure.

2. How do I determine the correct spacing between LVL slats for my project?

The ideal spacing between LVL slats depends on several factors, including the intended application, the load-bearing requirements, the span of the slats, and the type of material being supported. For example, roof sheathing might require closer slat spacing than a decorative wall paneling project. It’s always best to consult with a structural engineer or refer to manufacturer’s span tables to determine the appropriate spacing for your specific application.

3. Can I paint or stain LVL slats to match my desired aesthetic?

Yes, you can! LVL slats accept paint, stain, and other finishes just like traditional lumber. For optimal results, use a high-quality primer designed for use with engineered wood products before painting or staining. This will help the finish adhere properly and provide a more even and durable coating.

4. Are LVL slats more environmentally friendly than traditional lumber?

LVL slats are generally considered a more sustainable choice than traditional lumber for several reasons. They are typically manufactured from fast-growing, sustainably harvested wood species, and the use of veneers allows manufacturers to maximize the yield from each log, minimizing waste. Additionally, LVL’s exceptional durability and long lifespan contribute to its sustainability by reducing the need for frequent replacements.

5. Where can I find reliable suppliers of high-quality LVL slats?

Reputable building material suppliers and lumber yards are excellent resources for sourcing LVL slats. Look for suppliers who offer a wide selection of LVL products, including various grades, dimensions, and treatment options. Don’t hesitate to ask about their sourcing practices, product certifications, and customer support to ensure you’re partnering with a reliable supplier committed to quality and sustainability.