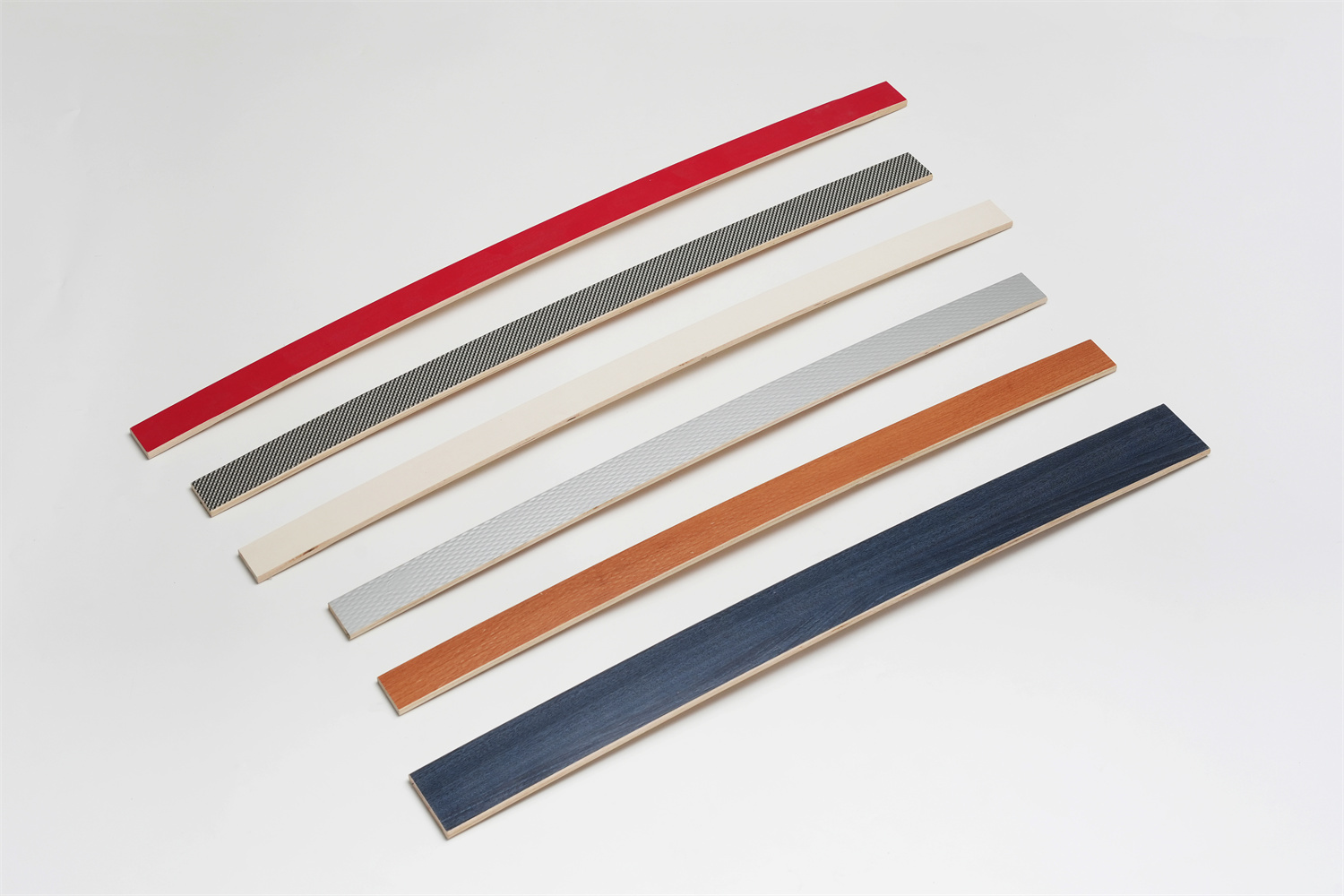

Foil Paper LVL Slats

Foil paper LVL slats: The ultimate solution for strong, moisture-resistant construction. Engineered for superior strength, stability, and durability, these slats feature a reflective foil facing that acts as a vapor barrier, preventing moisture damage. Ideal for roof & wall sheathing, flooring, and more, they offer exceptional performance and longevity for demanding projects.

Customization

Tailor products to meet your specific requirements.

Manufacturing

Consistent, durable products crafted with advanced techniques.

Logistics

Ensuring timely delivery to our clients worldwide.

share this product

The construction industry increasingly demands materials that offer superior strength, stability, and moisture resistance. Traditional materials often fall short, compromising structural integrity and longevity. Foil paper LVL slats address this need, providing a high-performance, moisture-resistant solution for various applications, from roof sheathing and wall framing to floor systems and agricultural buildings. They represent a transformative shift in construction, empowering builders with a reliable and durable solution.

What are Foil Paper LVL Slats?

Foil paper LVL slats represent a pinnacle of engineered wood technology, meticulously crafted to deliver an unmatched combination of strength, stability, and moisture resistance, making them an ideal choice for a wide range of demanding construction applications. These innovative building components begin with the inherent strength of LVL (Laminated Veneer Lumber), renowned for its exceptional structural properties that surpass those of traditional lumber in virtually every aspect. LVL is engineered by layering thin sheets of wood veneer, typically sourced from rapidly renewable, sustainably harvested softwood species such as Douglas Fir, Southern Pine, and Yellow Poplar, renowned for their strength, stiffness, and dimensional stability. These veneer layers are carefully arranged with their grain running in a parallel direction, a key factor in LVL’s exceptional strength and stability. This precise grain alignment minimizes the natural tendencies of wood to warp, twist, or shrink, ensuring that structures built with LVL remain true and strong over time.

To further elevate their moisture resistance and overall durability, LVL slats are then meticulously faced with a highly reflective aluminum foil layer. This foil facing serves as an impenetrable barrier against moisture, effectively preventing water vapor from penetrating and compromising the structural integrity of the LVL core. This protective layer is particularly crucial in demanding environments characterized by high humidity, frequent precipitation, or exposure to the elements, where traditional wood products would be highly susceptible to moisture-related damage such as rot, decay, and the growth of mold or mildew. Beyond its moisture-resistant properties, the foil facing also enhances the thermal performance of the slats, reflecting radiant heat away from the structure during scorching summer months and helping to retain precious heat during the colder winter months. This thermal advantage contributes to improved energy efficiency, reducing the load on heating and cooling systems, and ultimately fostering a more comfortable and environmentally responsible indoor environment.

Foil Paper LVL Slat Specifications

| Feature | Description |

| Wood Species |

Birch/Poplar/Eucalyptus

|

| Properties |

Exceptional strength-to-weight ratio, superior dimensional stability, consistent quality throughout the material, exceptional resistance to warping, twisting, and bowing, excellent fastener holding power, predictable structural performance, enhanced moisture resistance, and improved thermal performance. These properties make foil paper LVL slats an ideal choice for a wide range of demanding construction applications where strength, stability, and moisture resistance are paramount.

|

| Surface Finish |

With Decorative Paper

|

| Type |

Flat/ R4000/ R8000

|

| Dimensions |

Length:550-1750mm

Width:25-170mm Thickness:6-20mm |

| Glue Grade | E0, E1 |

| Moisture Content | 8-14% |

| Certificate |

FSC/ CARB P2/ EPA

|

Applications of Foil Paper LVL Slats

The remarkable versatility, exceptional performance characteristics, and inherent moisture resistance of foil paper LVL slats have propelled their widespread adoption across a diverse array of construction and building applications, including:

- Roof Sheathing: Foil paper LVL slats excel as roof sheathing, providing a strong, stable, and moisture-resistant substrate for various roofing materials, including asphalt shingles, metal roofing, and tile. Their superior strength and dimensional stability allow for wider spans between roof trusses or rafters, reducing the need for as much structural support, which in turn reduces material costs and simplifies framing layouts. The integrated foil facing acts as a radiant barrier, reflecting heat away from the attic space and improving the building’s overall energy efficiency. This thermal benefit contributes to a more comfortable indoor environment and has the potential to significantly reduce cooling costs, especially in warmer climates.

- Wall Sheathing: In exterior wall applications, foil paper LVL slats offer superior strength, stability, and moisture resistance compared to traditional sheathing materials like plywood or oriented strand board (OSB). Their exceptional dimensional stability ensures a flat, smooth surface for the application of siding or cladding materials, contributing to a more aesthetically pleasing finished appearance. The foil facing acts as a robust vapor barrier, preventing moisture intrusion and protecting the structural integrity of the wall assembly. This moisture resistance is particularly crucial in climates with high humidity or driving rain, where traditional sheathing materials may be susceptible to moisture damage.

- Floor Joists and Beams: The high strength-to-weight ratio and impressive dimensional stability of foil paper LVL slats make them an ideal choice for floor joists and beams, particularly in areas prone to moisture, such as crawl spaces, basements, or regions with high humidity. Their long lengths and consistent quality minimize the need for mid-span supports, allowing for more open floor plans and greater design flexibility. This reduced need for supports can open up interior spaces, making them feel larger and more inviting. Additionally, their resistance to warping, twisting, and shrinking ensures that floors remain level and squeak-free over time.

- Rim Board and Banding: Foil paper LVL slats are commonly employed as rim boards and banding around the perimeter of floors and roofs, providing a strong, moisture-resistant connection point for framing members. Their exceptional dimensional stability ensures a secure connection that resists warping or twisting over time, enhancing the overall structural integrity of the building and preventing potential issues down the road. This is particularly important in areas prone to seismic activity, where a strong, well-connected structure is essential for safety.

- Soffit and Fascia: The inherent moisture resistance and dimensional stability of foil paper LVL slats make them well-suited for soffit and fascia applications, where they are often exposed to the elements. The foil facing helps protect the LVL core from moisture damage, preventing rot, decay, and the growth of mold or mildew, while the dimensional stability ensures a straight, true edge that enhances the aesthetic appeal of the building. Their resistance to warping and twisting also ensures that soffits and fascias remain straight and true over time, even when exposed to harsh weather conditions.

- Agricultural Buildings: In the demanding environment of agricultural settings, foil paper LVL slats are utilized for a wide range of applications, including roof sheathing, wall sheathing, and structural framing for barns, sheds, stables, and other agricultural structures. The exceptional moisture resistance and durability of foil paper LVL slats make them exceptionally well-suited for these demanding environments, where they are routinely exposed to high humidity, fluctuating temperatures, and potential damage from livestock or equipment. Their resistance to mold, mildew, and insect infestation further adds to their suitability for agricultural applications.

Advantages of Foil Paper LVL Slats

Foil paper LVL slats offer a compelling array of advantages over traditional lumber and other building materials, establishing them as a superior choice for a wide range of construction applications:

- Exceptional Strength and Stability: The layered veneer construction and parallel grain orientation of LVL slats result in exceptional strength and dimensional stability, significantly outperforming traditional solid wood in bending, tension, and compression. This remarkable strength and stability allow for longer spans, reducing the need for intermediate supports, which translates to reduced material costs and greater design flexibility. Architects and builders can achieve more open floor plans, expansive rooms, and unique architectural features with the confidence that the structure will be sound and stable for years to come.

- Enhanced Moisture Resistance: The aluminum foil facing acts as a robust vapor barrier, effectively preventing moisture penetration and safeguarding the structural integrity of the LVL core. This enhanced moisture resistance makes foil paper LVL slats an ideal choice for applications where moisture is a concern, such as roof sheathing, exterior wall sheathing, and framing in crawl spaces or basements. This moisture resistance translates to greater longevity for the structure, reducing the risk of costly repairs or replacements due to moisture damage, which can be a significant concern with traditional wood products.

- Improved Thermal Performance: The reflective surface of the foil facing helps reflect radiant heat away from the structure, contributing to improved energy efficiency and a more comfortable indoor environment. This reflective property can significantly reduce cooling loads during the summer months and enhance heat retention during the winter months, potentially leading to lower energy bills and a reduced carbon footprint. This thermal performance benefit can be particularly significant in regions with extreme temperature swings, where maintaining a comfortable indoor temperature can be a challenge.

- Reduced Labor Costs: The lightweight nature of foil paper LVL slats, coupled with their long lengths and ease of installation, can significantly reduce labor costs compared to traditional lumber. Their consistent quality and straightness minimize the need for on-site cutting and waste, further streamlining the construction process and reducing material waste. This ease of installation can be a significant advantage in today’s construction industry, where skilled labor is often in short supply and high demand.

- Sustainability: Engineered wood products like foil paper LVL slats represent a more sustainable building material choice compared to traditional lumber. They are manufactured from sustainably sourced wood resources, and the efficient use of timber in the veneer peeling process minimizes waste. Their long lifespan and durability contribute to a lower overall environmental footprint, making them a responsible choice for environmentally conscious builders and homeowners. By choosing foil paper LVL slats, you are making a conscious decision to support sustainable forestry practices and reduce the environmental impact of your construction project.

Foil Paper LVL Slats vs. Traditional Lumber

| Feature | Foil Paper LVL Slats | Traditional Lumber |

|---|---|---|

| Strength | Significantly higher strength-to-weight ratio, allowing for longer spans and greater design flexibility. This means fewer support beams are needed, which can translate to lower material costs and more open floor plans. | Lower strength-to-weight ratio, often requiring more frequent supports and limiting design options. This can lead to higher material costs and a more cluttered appearance with more visible beams and supports. |

| Stability | Exceptional dimensional stability, resisting warping, twisting, and bowing even in fluctuating environmental conditions. This ensures that structures built with foil paper LVL slats remain straight and true over time, even in challenging climates. | Susceptible to warping, twisting, and bowing due to moisture fluctuations, potentially leading to structural issues and aesthetic imperfections. This can lead to costly repairs and a shorter lifespan for the structure. |

| Moisture Resistance | Enhanced moisture resistance due to foil facing, protecting the structural integrity of the LVL core and minimizing the risk of mold, mildew, or rot. This makes foil paper LVL slats ideal for use in areas prone to moisture, such as crawl spaces, basements, and exterior walls. | Susceptible to moisture damage, requiring additional treatments and potentially compromising structural integrity over time. This can lead to costly repairs and a shorter lifespan for the structure. |

| Thermal Performance | Improved thermal performance due to reflective foil facing, contributing to energy efficiency and a more comfortable indoor environment. This can lead to lower energy bills and a reduced carbon footprint. | Lower thermal performance, potentially leading to higher energy bills and less comfortable living or working spaces. This can make it more difficult and expensive to maintain a comfortable indoor temperature. |

| Installation | Faster and easier to install due to lightweight nature, long lengths, and consistent quality, reducing labor costs and construction time. This can be a significant advantage in today’s construction industry, where skilled labor is often in high demand. | More time-consuming and labor-intensive to install due to heavier weight, shorter lengths, and potential for warping or twisting, increasing labor costs and extending construction timelines. This can add significant costs to a construction project. |

| Sustainability | More sustainable due to efficient use of timber resources, sourcing from sustainably managed forests, and contributing to a lower overall environmental footprint. This makes foil paper LVL slats a responsible choice for environmentally conscious builders and homeowners. | Less sustainable due to potential for waste generation, reliance on less renewable resources, and a higher overall environmental impact. This can be a concern for builders and homeowners who are trying to minimize their environmental impact. |

Why Choose YuanTuo Wood for Foil Paper LVL Slats?

At YuanTuo Wood, we are driven by an unwavering commitment to providing our valued customers with the highest quality engineered wood products and exceptional customer service. We understand that selecting the right building materials is paramount to the success of any construction endeavor, and we are dedicated to being your trusted partner throughout the process, providing not only exceptional products but also the in-depth knowledge and unwavering support you need to make informed decisions that align with your project’s unique requirements. Our foil paper LVL slats are a testament to this commitment, offering superior performance, unmatched durability, and robust moisture resistance for your most demanding and intricate projects.

- Uncompromising Quality: We source our veneers from responsibly managed forests and employ state-of-the-art manufacturing processes to ensure that our foil paper LVL slats consistently meet or exceed the most stringent industry standards. Our rigorous quality control measures are integrated into every stage of production, from the meticulous selection of premium veneers to the precise application of moisture-resistant adhesives, the controlled pressing and facing processes, and the final inspection of every single slat that leaves our facility. This unwavering commitment to quality ensures that you receive a product that meets the highest standards of performance, durability, and reliability.

- Tailored Customization Options: We recognize that every project is unique, with its own set of specific requirements and design considerations. That’s why we offer a wide range of customization options to meet your specific needs, including size, grade, and treatment specifications. Whether you require a specific length, thickness, or width, or need a specific treatment to meet local building codes or environmental conditions, our team can work with you to develop a tailored solution that meets your exact specifications.

- Unparalleled Technical Expertise: Our team of seasoned engineers and technical specialists is always available to provide expert guidance and unwavering support throughout your project’s lifecycle, from the initial design consultations, where we can help you select the right products and develop structurally sound and cost-effective designs, to on-site installation assistance, ensuring that your project is completed to the highest standards. We understand that building codes and regulations can be complex and ever-changing, and we are here to help you navigate these requirements, ensuring your project meets all applicable standards and regulations.

- Stewardship of Our Forests: We are deeply committed to sustainable forestry practices and responsible sourcing, minimizing our environmental impact at every stage of the product lifecycle, from the forests where our veneers are harvested to the manufacturing process and beyond. We believe that responsible forestry is not just good practice but essential for the long-term health of our planet and the sustainability of the wood products industry as a whole. By choosing YuanTuo Wood, you are supporting sustainable forestry practices and making a responsible choice for the environment.

Frequently Asked Questions (FAQ)

1. Can foil paper LVL slats be used in exterior applications where they are directly exposed to the elements for extended periods?

While the foil facing provides exceptional moisture resistance, direct and prolonged exposure to the elements, particularly the sun’s ultraviolet (UV) radiation, is not recommended. Over time, UV radiation can degrade the foil facing, potentially compromising its moisture resistance and leading to premature deterioration. For exterior applications, it’s essential to incorporate additional protective measures, such as siding, trim, or a waterproof membrane, to shield the foil facing from direct exposure to the elements and ensure long-term performance and protection. This will help to extend the lifespan of the product and maintain its aesthetic appeal.

2. What type of adhesive is used to bond the foil facing to the LVL core, and is it designed to withstand exposure to moisture?

We utilize a high-performance, moisture-resistant adhesive specifically engineered for bonding foil to wood products. This specialized adhesive is formulated to withstand prolonged exposure to moisture, temperature fluctuations, and the inherent stresses of the construction environment, ensuring a durable, long-lasting bond between the foil facing and the LVL core. This robust bond is critical to maintaining the moisture resistance and overall integrity of the product, even in demanding applications.

3. Are foil paper LVL slats compatible with standard woodworking tools and fasteners?

Yes, foil paper LVL slats can be cut, drilled, and shaped using standard woodworking tools, similar to traditional lumber. However, it’s important to note that the density of LVL requires the use of sharp, high-quality tools and potentially slower cutting speeds to achieve clean, precise cuts and prevent damage to the material or the tool itself. For fastening, it’s recommended to use high-quality screws or nails specifically designed for use with engineered wood products. These fasteners are typically coated with a corrosion-resistant finish to prevent rusting and ensure a secure, long-lasting hold in the dense LVL material.

4. Do foil paper LVL slats require any special handling or storage considerations?

Proper storage is crucial for preserving the quality and performance of foil paper LVL slats. They should be stored in a dry, well-ventilated area, protected from direct sunlight and moisture. It’s essential to keep the slats elevated off the ground to prevent moisture absorption from below and to allow for proper air circulation. Covering the slats with a breathable material, such as a tarp, can provide additional protection from dust, debris, and moisture.

5. Is foil paper LVL slat pricing competitive with traditional lumber or other engineered wood products?

While the initial cost of foil paper LVL slats may be slightly higher than traditional lumber, the long-term cost savings and performance advantages often outweigh the initial price difference. The exceptional strength and stability of LVL slats allow for longer spans and fewer support structures, potentially reducing material costs. Additionally, their enhanced moisture resistance and durability translate to lower maintenance costs and a longer lifespan, further contributing to long-term cost savings. When compared to other engineered wood products, foil paper LVL slats offer a competitive balance of performance, moisture resistance, and cost-effectiveness, making them a compelling choice for a wide range of applications.

01.

Veneer

High-quality veneer sheets are selected as the base material.

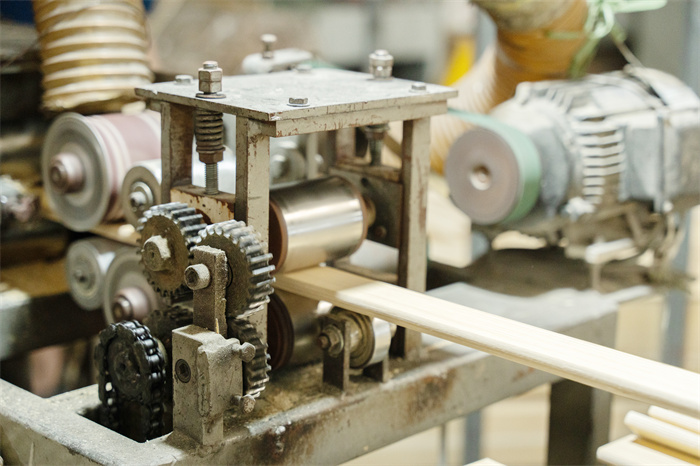

02.

Veneer Drying

Dried to the ideal moisture content for stability.

03.

Glue Spreading

Applied evenly to ensure a strong bond between layers.

04.

Assembly

Glued sheets are aligned and layered for pressing.

05.

Cold Press Forming

Layers are cold-pressed to set the initial bond.

06.

Hot press

High pressure and heat finalize the bond and product shape.

07.

Cutting edge

Boards are trimmed to exact dimensions.

08.

Cutting

Trimmed boards are cut to specific sizes.

09.

Chamfering

Edges are smoothed for a clean finish.

10.

Nail the straps

Straps are added for strength and easy handling.

11.

Packing

Products are carefully packed for protection.

12.

Delivery

Finished products are shipped to customers.