In un'epoca di crescente consapevolezza ambientale, i produttori di tutti i settori cercano alternative sostenibili ai materiali tradizionali. Una di queste alternative, spesso trascurata, è l'eco-compatibilità. compensato. Lontano dalla sua reputazione di materiale puramente funzionale, il compensato ecologico offre una miscela convincente di sostenibilità, durata e fascino estetico, che lo rende una scelta intelligente per il produttore moderno.

Comprendere il compensato ecologico: Cosa lo rende diverso?

Il compensato ecologico si distingue da quello convenzionale per l'approvvigionamento, il processo di produzione e l'impegno costante per la sostenibilità. Approfondiamo le differenze principali:

1. Approvvigionamento sostenibile: La base del compensato ecologico

- Foreste gestite in modo responsabile: Un impegno per la salute delle foreste a lungo termine A differenza del compensato proveniente da foreste disboscate indiscriminatamente, il compensato ecologico proviene da foreste certificate da organizzazioni affidabili come il Forest Stewardship Council (FSC) o il Programme for the Endorsement of Forest Certification (PEFC). Queste certificazioni servono a garantire che il legno sia tagliato in modo responsabile, tenendo conto dell'impatto ecologico sull'ecosistema forestale. Ciò garantisce non solo la salute e la biodiversità della foresta a lungo termine, ma rispetta anche i diritti e i mezzi di sussistenza delle comunità locali che dipendono da queste foreste.

- Specie a crescita rapida: Una risorsa rinnovabile per un futuro sostenibile Molte opzioni di compensato ecologico utilizzano specie legnose a crescita rapida come il bambù o il pioppo. Queste specie hanno cicli di crescita incredibilmente rapidi, che talvolta raggiungono la maturità in una sola stagione di crescita, a differenza dei legni duri a crescita più lenta che possono richiedere decenni. Questa rapida rinnovabilità riduce significativamente la pressione sulle foreste di vecchia crescita e promuove pratiche di gestione forestale sostenibile, fornendo una fonte di legname prontamente rinnovabile.

- Contenuto riciclato: Chiudere il cerchio e ridurre al minimo i rifiuti Facendo un ulteriore passo avanti nella sostenibilità, alcuni produttori di compensato ecologico incorporano nei loro prodotti fibre di legno riciclato. Questo può includere legno di scarto post-consumo, sottraendolo alle discariche e dandogli una nuova vita sotto forma di compensato resistente. Questa pratica riduce ulteriormente la domanda di legname vergine, diminuendo l'impatto ambientale complessivo associato al disboscamento e al trasporto.

2. Produzione eco-compatibile: Ridurre al minimo l'impronta dall'inizio alla fine della produzione

- Adesivi a basso contenuto di COV: Privilegiare la qualità dell'aria interna e la salute dei lavoratori Il compensato tradizionale impiega spesso adesivi contenenti formaldeide, un composto organico volatile (VOC) dannoso e noto per il suo impatto negativo sulla qualità dell'aria interna e sulla salute umana. Il compensato ecologico adotta un approccio diverso, utilizzando adesivi a basso contenuto di COV o privi di formaldeide, spesso optando per alternative a base di soia o acqua, più sicure sia per i lavoratori che per gli utenti finali. Questo impegno a favore di adesivi più sani garantisce un ambiente interno più sicuro e riduce al minimo il rilascio di emissioni nocive durante il processo di produzione.

- Riduzione del consumo energetico: Efficienza in ogni fase della produzione Molti produttori di compensato ecologico danno priorità all'efficienza energetica nei loro processi produttivi, riconoscendo che la minimizzazione dell'uso di energia è fondamentale per ridurre l'impronta di carbonio. Ciò può comportare un approccio multiforme, che comprende l'utilizzo di fonti di energia rinnovabili come l'energia solare o eolica, l'ottimizzazione dei flussi di lavoro per ridurre gli sprechi energetici e l'implementazione di attrezzature e tecnologie ad alta efficienza energetica. Questo impegno olistico per un'impronta ambientale più leggera contribuisce a un ciclo produttivo più sostenibile, dall'approvvigionamento delle materie prime al prodotto finale.

I vantaggi della scelta di un compensato ecologico per la vostra azienda

I vantaggi dell'integrazione del compensato ecologico nei vostri processi produttivi vanno ben oltre la responsabilità ambientale. Ecco perché ha un senso commerciale nel mercato attuale:

1. Miglioramento dell'immagine del marchio e della fedeltà dei clienti: Allinearsi ai valori dei consumatori

Nel mercato odierno, in cui i consumatori sono sempre più consapevoli dell'impatto ambientale e sociale delle loro decisioni di acquisto, i marchi che danno priorità alla sostenibilità hanno un netto vantaggio. Incorporando nei vostri prodotti materiali ecologici come il compensato, dimostrate un impegno tangibile verso la responsabilità ambientale, un valore che risuona fortemente con il consumatore consapevole di oggi. Questo può essere un potente elemento di differenziazione per il vostro marchio, migliorando la vostra immagine e promuovendo la fedeltà dei consumatori attenti all'ambiente, che cercano attivamente aziende allineate ai loro valori.

2. Soddisfare gli standard di bioedilizia: Sfruttare un mercato in crescita

Con l'affermarsi della sostenibilità nel settore delle costruzioni, le certificazioni di bioedilizia come LEED (Leadership in Energy and Environmental Design) stanno guadagnando importanza. Queste certificazioni forniscono un quadro di riferimento per la creazione di edifici più sani, efficienti e responsabili dal punto di vista ambientale. Incentivano i costruttori e gli sviluppatori a utilizzare materiali e pratiche eco-compatibili durante l'intero processo di costruzione. Il compensato ecologico, con le sue caratteristiche di provenienza responsabile e di basso contenuto di COV, può contribuire con punti preziosi al raggiungimento di queste certificazioni. Ciò rende i vostri prodotti più attraenti per i costruttori e gli sviluppatori attenti all'ambiente che cercano soluzioni edilizie sostenibili che soddisfino i rigorosi standard ambientali, offrendovi un vantaggio competitivo in questo segmento di mercato in crescita.

3. Durata e longevità: Qualità che resiste alla prova del tempo

Non lasciatevi ingannare dall'etichetta "eco-friendly": questo compensato è tutt'altro che fragile. Il legno di provenienza sostenibile, se prodotto correttamente con adesivi e tecniche di alta qualità, può essere altrettanto resistente e duraturo del compensato tradizionale. Questa durabilità si traduce in prodotti con una durata maggiore, riducendo la necessità di frequenti sostituzioni e minimizzando gli sprechi nel lungo periodo. Questa longevità testimonia che i materiali ecologici possono essere altrettanto performanti delle loro controparti convenzionali, sfatando il mito che la sostenibilità vada a scapito della qualità.

4. Versatilità di progettazione e applicazione: Un materiale per diversi settori industriali

Il compensato ecologico è incredibilmente versatile e può essere utilizzato in un'ampia gamma di applicazioni in diversi settori, diventando così il materiale preferito dai produttori che cercano soluzioni sostenibili senza compromettere il design o la funzionalità. Ecco alcuni esempi della sua versatilità:

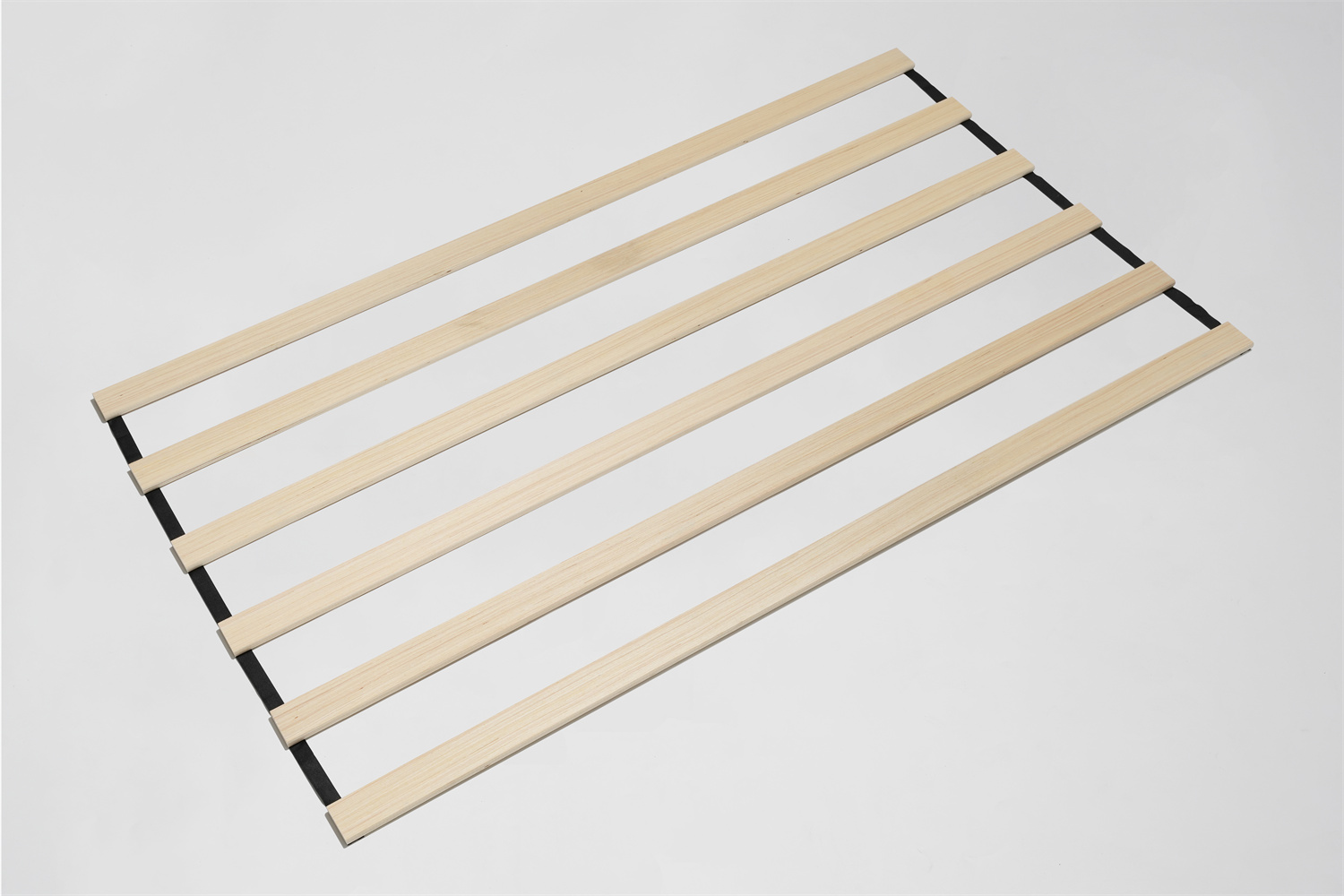

- Produzione di mobili: Realizzare pezzi sostenibili ed eleganti Dall'elegante design moderno all'estetica rustica della fattoria, il compensato ecologico può essere trasformato in splendidi e durevoli pezzi d'arredo che soddisfano le esigenze dei consumatori più esigenti. La sua resistenza, la lavorabilità e la capacità di assumere varie finiture lo rendono un materiale ideale per un'ampia gamma di mobili, tra cui sedie, tavoli, scrivanie, scaffali, strutture per letti e altro ancora. I produttori di mobili si rivolgono sempre più spesso al compensato ecologico per soddisfare la crescente domanda di mobili sostenibili che siano al tempo stesso eleganti e rispettosi dell'ambiente.

- Edilizia e costruzioni: Costruire un futuro più verde, una struttura alla volta La sua resistenza e stabilità intrinseca rendono il compensato ecologico ideale per una varietà di applicazioni strutturali nel settore edile, tra cui rivestimenti di pareti, sottofondi e coperture. La sua resistenza all'umidità, in particolare nel compensato marino, lo rende adatto agli ambienti umidi e alle applicazioni esterne. I costruttori ne riconoscono sempre più il valore nella creazione di strutture sostenibili e durevoli, che soddisfano le severe norme edilizie e riducono al minimo l'impatto ambientale.

- Progettazione e allestimento di interni: Creare spazi sani ed esteticamente piacevoli Il compensato ecologico può essere utilizzato per creare elementi interni belli e sostenibili, tra cui pannelli a parete, soffitti, armadietti e elementi decorativi. La sua estetica calda e la possibilità di essere mordenzato o dipinto in una varietà di colori e finiture lo rendono una scelta versatile per i progettisti di interni che cercano di creare spazi sani ed eleganti che promuovano il benessere. Le sue proprietà a basso contenuto di COV contribuiscono a migliorare la qualità dell'aria interna, rendendolo un'opzione particolarmente interessante per case, uffici e spazi commerciali in cui la salute e la sostenibilità sono fondamentali.

- Imballaggio e spedizione: Proteggere le merci e il pianeta Leggero ma sorprendentemente resistente, il compensato ecologico rappresenta un'alternativa sostenibile ai materiali di imballaggio tradizionali come il cartone o la plastica, che spesso finiscono in discarica. La sua resistenza garantisce un trasporto sicuro delle merci, mentre la sua riciclabilità lo rende una scelta ecologicamente responsabile per le aziende che desiderano ridurre al minimo i rifiuti da imballaggio e l'impatto ambientale.

Confronto tra le opzioni di compensato ecologico: Una guida rapida

| Tipo di compensato | Caratteristiche | Applicazioni | Caratteristiche di sostenibilità |

|---|---|---|---|

| Compensato certificato FSC | Provengono da foreste gestite in modo responsabile, garantendo la salute e la biodiversità a lungo termine degli ecosistemi forestali. Il processo di certificazione FSC tiene conto anche del benessere sociale ed economico dei lavoratori del settore forestale. | Arredamento, edilizia, design d'interni: qualsiasi applicazione in cui l'approvvigionamento responsabile è fondamentale e l'impatto ambientale è una considerazione chiave. | Assicura una gestione responsabile delle foreste, la conservazione della biodiversità e il benessere sociale ed economico dei lavoratori del settore forestale. |

| Compensato di bambù | Realizzato in bambù a crescita rapida, noto per la sua forza, flessibilità e resistenza naturale a parassiti e umidità. Il bambù è una risorsa altamente rinnovabile e raggiunge la maturità molto più rapidamente dei legni duri tradizionali. | Mobili, pavimenti, rivestimenti: applicazioni che beneficiano delle proprietà uniche e dell'estetica del bambù. Il suo rapporto forza-peso lo rende particolarmente adatto ai mobili e alle applicazioni strutturali. | La rapida rinnovabilità - il bambù può essere raccolto in 3-5 anni, rispetto ai decenni dei legni duri tradizionali - lo rende una scelta altamente sostenibile con un impatto ambientale significativamente inferiore. |

| Compensato di pioppo | Utilizza pioppi a crescita rapida, offrendo un'opzione leggera, facilmente disponibile e conveniente per i produttori che cercano un'alternativa sostenibile ai legni duri a crescita più lenta. | Mobili, armadi, applicazioni interne in cui si desidera un compensato più leggero senza compromettere la resistenza o la stabilità. | Ciclo di crescita rapido - i pioppi maturano rapidamente, riducendo la pressione sulle specie a crescita più lenta e contribuendo alle pratiche di gestione forestale sostenibile. |

| Compensato a contenuto riciclato | Incorpora fibre di legno riciclato, sottraendo rifiuti alle discariche e riducendo la domanda di legname vergine. La percentuale di contenuto riciclato può variare a seconda del produttore e del prodotto specifico. | Imballaggi, edilizia, mobili - applicazioni in cui il contenuto riciclato aggiunge un profilo di sostenibilità al prodotto e si rivolge a consumatori attenti all'ambiente. | Riduce gli sprechi, promuove i principi dell'economia circolare dando ai materiali una seconda vita e riduce l'impatto ambientale associato all'estrazione e alla lavorazione del legno vergine. |

Fare il cambio: Integrare il compensato ecologico nelle vostre operazioni

Passare al compensato ecologico non deve essere un compito scoraggiante. Ecco come iniziare:

- Collaborare con fornitori affidabili: Cercare trasparenza e certificazione Prendetevi il tempo necessario per ricercare e collaborare con fornitori di compensato che danno priorità alla trasparenza e forniscono certificazioni che verificano la sostenibilità dei loro prodotti. Non esitate a fare domande sulle loro pratiche di approvvigionamento e produzione per assicurarvi che siano in linea con i valori di sostenibilità della vostra azienda. Cercate certificazioni di organizzazioni affidabili come FSC o PEFC, che indicano che il legno utilizzato nel compensato proviene da foreste gestite in modo responsabile.

- Educare il team: Dare forza alla vostra forza lavoro per abbracciare la sostenibilità Fornite una formazione completa ai vostri team di progettazione, produzione e vendita sui vantaggi e le applicazioni del compensato ecologico. Fornite loro le conoscenze e le risorse necessarie per comprendere i diversi tipi di compensato ecologico, le loro proprietà uniche e come comunicare efficacemente ai clienti la proposta di valore di questi materiali sostenibili. Più il vostro team è informato, più sarà in grado di abbracciare questa alternativa sostenibile e di farsi portavoce del suo utilizzo all'interno della vostra azienda.

- Comunicare con i clienti: La trasparenza crea fiducia La trasparenza è fondamentale quando si tratta di dichiarazioni di sostenibilità. Comunicate chiaramente ai vostri clienti gli attributi sostenibili dei vostri prodotti, evidenziando i vantaggi ambientali della scelta del compensato ecologico. Siate specifici sul tipo di compensato ecologico che utilizzate, sulle sue origini e sulle certificazioni di cui è in possesso. Questa trasparenza crea fiducia nei consumatori, sempre più attenti alla sostenibilità dei prodotti che acquistano.

Compensato ecologico: Risposte alle vostre domande

1. Il compensato ecologico è resistente e durevole come il compensato tradizionale?

Sì, il compensato ecologico può essere altrettanto resistente e durevole di quello tradizionale, soprattutto se prodotto correttamente utilizzando legno di alta qualità e di provenienza sostenibile e adesivi durevoli e a basso contenuto di COV. Non lasciatevi ingannare dall'etichetta "eco": questi materiali sono progettati per garantire prestazioni e durata.

2. Quali tipi di progetti sono più adatti al compensato ecologico?

Il compensato ecologico è incredibilmente versatile! È adatto a un'ampia gamma di progetti, tra cui la costruzione di mobili, l'edilizia (rivestimenti per pareti, sottofondi, coperture), elementi di design per interni (pannelli per pareti, soffitti) e persino soluzioni di imballaggio sostenibili.

3. Come posso essere sicuro che il compensato che sto acquistando sia veramente ecologico?

Cercate certificazioni credibili come quelle del Forest Stewardship Council (FSC) o del Programme for the Endorsement of Forest Certification (PEFC). Queste certificazioni garantiscono che il legno proviene da foreste gestite in modo responsabile. Non esitate a chiedere ai fornitori informazioni sulle loro pratiche di approvvigionamento e produzione.

4. Il compensato ecologico è più costoso di quello tradizionale?

Anche se il prezzo può variare a seconda di fattori quali le specie legnose e il produttore, il compensato ecologico ha spesso un prezzo competitivo rispetto alle opzioni convenzionali. Con la crescita della domanda di materiali sostenibili, è probabile che il divario di prezzo si riduca ulteriormente.

5. Dove posso trovare fornitori affidabili di compensato ecologico?

Iniziate facendo ricerche online e contattando direttamente i fornitori. Anche le associazioni di settore e gli elenchi online specializzati in materiali da costruzione sostenibili possono essere risorse preziose. Per avere un consiglio, considerate di esplorare Yuantuo Wood, un'azienda nota per il suo impegno a favore di pratiche forestali sostenibili e di prodotti di compensato ecologico di alta qualità.

Il futuro è sostenibile: Abbracciare il potenziale del compensato ecologico

Poiché le aziende di tutti i settori danno sempre più priorità alla sostenibilità come valore fondamentale e motore dell'innovazione, il compensato ecologico è pronto a diventare il materiale preferito dai produttori che cercano di ridurre l'impatto ambientale senza compromettere la qualità o le prestazioni. Abbracciando questo materiale versatile e sostenibile, non solo contribuite a un pianeta più sano, ma posizionate anche la vostra azienda in prima linea in un mercato in crescita che apprezza sia la qualità che la responsabilità ambientale. I consumatori, sempre più consapevoli dell'impatto delle loro scelte, cercano sempre più spesso prodotti e marchi in linea con i loro valori. Scegliendo il compensato ecologico, non solo prendete una decisione commerciale responsabile, ma attingete anche a un mercato che cerca attivamente soluzioni sostenibili.