Production Process

01.

Veneer

High-quality veneer sheets are selected as the base material.

02.

Veneer Drying

Dried to the ideal moisture content for stability.

03.

Glue Spreading

Applied evenly to ensure a strong bond between layers.

04.

Assembly

Glued sheets are aligned and layered for pressing.

05.

Cold Press Forming

Layers are cold-pressed to set the initial bond.

06.

Hot press

High pressure and heat finalize the bond and product shape.

07.

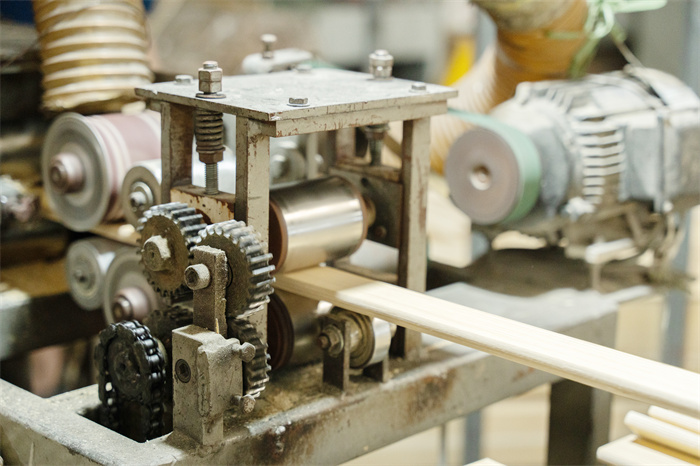

Cutting edge

Boards are trimmed to exact dimensions.

08.

Cutting

Trimmed boards are cut to specific sizes.

09.

Chamfering

Edges are smoothed for a clean finish.

10.

Nail the straps

Straps are added for strength and easy handling.

11.

Packing

Products are carefully packed for protection.

12.

Delivery

Finished products are shipped to customers.