W wymagającej dziedzinie budownictwa, gdzie integralność strukturalna jest najważniejsza, wybór odpowiednich materiałów może zadecydować o powodzeniu lub porażce projektu. Gdy projekty wymagają wyjątkowej wytrzymałości, stabilności wymiarowej i odporności na wilgoć, fornir LVL (Laminowana tarcica fornirowana) listwy stają się najlepszym rozwiązaniem. A jeśli chodzi o pozyskiwanie tych wysokowydajnych bloków konstrukcyjnych, Chiny są światowym liderem, oferując dynamiczny krajobraz producentów gotowych spełnić Twoje specyficzne potrzeby.

Ten kompleksowy przewodnik służy jako kompas, nawigujący po zawiłościach pozyskiwania fornirowanych listew LVL z Chin. Zapewnimy Ci wiedzę, spostrzeżenia i praktyczne wskazówki, które pozwolą Ci pewnie wybrać dostawcę, który spełni Twoje wymagania projektowe, oczekiwania jakościowe i budżetowe, zapewniając płynne doświadczenie od wstępnego zapytania do zakończenia projektu.

Dlaczego fornirowane listwy LVL? Nauka stojąca za wytrzymałością

Zanim wyruszymy w podróż zaopatrzeniową, zagłębmy się w naukę stojącą za fornirowanymi listwami LVL i zrozummy, dlaczego stały się one wyborem dla wymagających budowniczych, architektów i wykonawców na całym świecie:

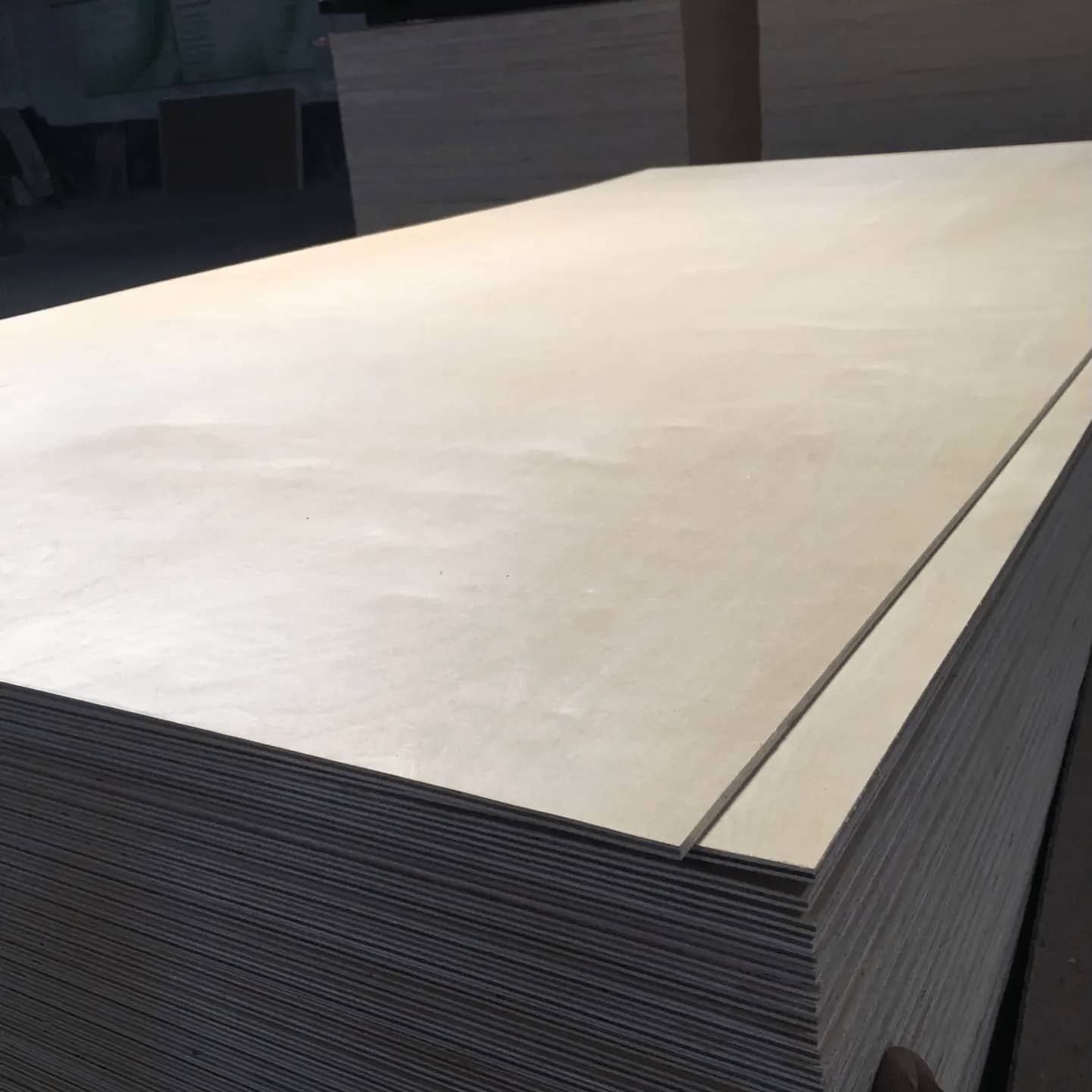

- Zaprojektowany z myślą o najwyższej jakości: W przeciwieństwie do tradycyjnej litej tarcicy, podatnej na niespójności, sęki i nieodłączne słabości, LVL jest skrupulatnie zaprojektowany pod kątem wyjątkowej wytrzymałości i stabilności. Cienkie arkusze forniru drewnianego, zazwyczaj pozyskiwane z szybko rosnących, pozyskiwanych w sposób zrównoważony gatunków drewna iglastego, są łączone ze sobą pod intensywnym ciśnieniem i ciepłem. Ziarno każdej warstwy forniru jest strategicznie wyrównane równolegle, tworząc materiał kompozytowy, który znacznie przewyższa wytrzymałość i stabilność wymiarową swojego naturalnego odpowiednika.

- Siła, która przeczy oczekiwaniom: Unikalna krzyżowo laminowana struktura LVL zapewnia imponujący stosunek wytrzymałości do masy, co oznacza, że może ona przenosić znacznie większe obciążenia i rozpiętość na większe odległości niż tradycyjna tarcica, przy jednoczesnym zużyciu mniejszej ilości materiału. Ta wyjątkowa wytrzymałość otwiera świat możliwości projektowych, pozwalając na większe otwarte przestrzenie, mniejsze zapotrzebowanie na pośrednie kolumny wsporcze oraz możliwość uzyskania efektownych elementów architektonicznych bez uszczerbku dla integralności strukturalnej.

- Trwała odporność na wilgoć: Dodanie okleiny, często wykonanej z materiałów odpornych na wilgoć, takich jak żywica fenolowa lub przetworzony papier, dodatkowo zwiększa odporność LVL na warunki atmosferyczne. Ta warstwa ochronna działa jak bariera, zapobiegając wnikaniu wilgoci i minimalizując ryzyko wypaczenia, pęcznienia lub gnicia, dzięki czemu idealnie nadaje się do wymagających środowisk, zastosowań zewnętrznych i obszarów podatnych na wahania wilgotności.

Chiny: Strategiczne centrum zaopatrzenia w fornirowane listwy LVL

Chiny strategicznie pozycjonują się jako globalna potęga produkcyjna, a rynek LVL nie jest wyjątkiem. Oto dlaczego pozyskiwanie fornirowanych listew LVL z Chin ma strategiczny i finansowy sens dla profesjonalistów z branży budowlanej na całym świecie:

- Konkurencyjne ceny: Solidny i wysoce konkurencyjny krajobraz produkcyjny Chin, charakteryzujący się dużymi zakładami produkcyjnymi, wydajnymi łańcuchami dostaw, dostępem do obfitych surowców i wykwalifikowaną siłą roboczą, pozwala dostawcom oferować wysoce konkurencyjne ceny fornirowanych listew LVL bez uszczerbku dla jakości. Ta opłacalność sprawia, że zaopatrzenie z Chin jest atrakcyjną opcją dla projektów każdej wielkości, od małych renowacji budynków mieszkalnych po duże inwestycje komercyjne.

- Zaawansowana wydajność produkcji: Chińscy producenci poczynili znaczące inwestycje w najnowocześniejszą technologię i sprzęt zaprojektowany specjalnie do produkcji LVL. Te zaawansowane możliwości produkcyjne zapewniają wysokiej jakości listwy, które konsekwentnie spełniają lub przekraczają międzynarodowe standardy, zapewniając spokój ducha i pewność co do wydajności, trwałości i długoterminowej integralności strukturalnej materiału.

- Elastyczność dostosowywania: W przeciwieństwie do wielu dostawców tarcicy ograniczonych do standardowych rozmiarów i specyfikacji, chińscy producenci listew LVL są często bardzo elastyczni i otwarci na prośby o dostosowanie. Pozwala to na bezpośrednią współpracę z dostawcą w celu dostosowania wymiarów, rodzaju okleiny (żywica fenolowa, papier poddany obróbce itp.), opcji obróbki (ognioodporne, odstraszające owady) i innych specyfikacji do dokładnych potrzeb projektu. Taki poziom dostosowania zapewnia idealne dopasowanie, optymalną wydajność i minimalizuje ilość odpadów materiałowych, przyczyniając się do oszczędności kosztów i bardziej zrównoważonego procesu budowy.

Poruszanie się po procesie selekcji: Kluczowe czynniki do rozważenia

Wybór odpowiedniego dostawcy spośród szerokiego i dynamicznego krajobrazu chińskich producentów wymaga starannego rozważenia i strategicznego podejścia. Oto zestawienie kluczowych czynników, które należy ocenić podczas oceny potencjalnych dostawców fornirowanych listew LVL:

- Zapewnienie jakości: Kamień węgielny niezawodnego produktu

- Certyfikaty: Gwarancja jakości: Priorytetowo traktuj dostawców, którzy uzyskali uznawane na całym świecie certyfikaty, takie jak ISO 9001 (systemy zarządzania jakością) i ISO 14001 (systemy zarządzania środowiskowego). Certyfikaty te świadczą o zaangażowaniu w utrzymywanie rygorystycznych standardów kontroli jakości w całym procesie produkcyjnym, od pozyskiwania surowców po kontrolę produktu końcowego, zapewniając, że otrzymujesz produkt o stałej wysokiej jakości, który spełnia lub przewyższa standardy branżowe.

- Testy zewnętrzne: Niezależna weryfikacja: Nie wahaj się poprosić o szczegółowe raporty z niezależnych laboratoriów badawczych. Raporty te zapewniają bezstronną weryfikację krytycznych właściwości listew LVL, w tym wytrzymałości na zginanie, modułu sprężystości (sztywności), zawartości wilgoci, poziomów emisji formaldehydu (szczególnie ważnych w zastosowaniach wewnętrznych), odporności ogniowej i innych istotnych wskaźników wydajności.

- Audyty fabryczne: Świadek doskonałości z pierwszej ręki: Jeśli to możliwe, należy rozważyć przeprowadzenie (lub wynajęcie renomowanej firmy zewnętrznej do przeprowadzenia) audytu fabryki. Pozwoli to ocenić procesy produkcyjne dostawcy, środki kontroli jakości, warunki panujące w zakładzie i ogólne zaangażowanie w jakość z pierwszej ręki, zapewniając bezcenny wgląd w jego działalność i dając większą pewność co do jego zdolności do spełnienia określonych wymagań.

- Doświadczenie i wiedza specjalistyczna: Udokumentowane sukcesy

- Lata działalności: Doświadczenie ma znaczenie: Wybieraj dostawców z udokumentowaną historią i znaczącym doświadczeniem w produkcji fornirowanych listew LVL. Dłuższa historia w branży często wskazuje na ugruntowane procesy produkcyjne, wykwalifikowaną siłę roboczą, dogłębne zrozumienie właściwości i zastosowań materiału oraz zaangażowanie w zadowolenie klienta.

- Portfolio projektów: Dowód możliwości: Poproś o przykłady poprzednich projektów, w których dostawca dostarczył podobne produkty. Zapewnia to cenny wgląd w ich możliwości, skalę projektów, które obsługują, ich zdolność do zaspokajania różnorodnych potrzeb klientów, ich doświadczenie w różnych zastosowaniach (mieszkalnych, komercyjnych, przemysłowych) oraz ich osiągnięcia w dostarczaniu udanych wyników.

- Wiedza techniczna: Twój partner w rozwiązywaniu problemów: Upewnij się, że dostawca dysponuje kompetentnym i doświadczonym zespołem technicznym, który może udzielić Ci wsparcia w trakcie całego procesu pozyskiwania i realizacji projektu. Zespół ten powinien być w stanie udzielić wyczerpujących odpowiedzi na pytania techniczne, udzielić wskazówek dotyczących wyboru i zastosowania produktu, zaoferować niestandardowe rozwiązania dostosowane do unikalnych wymagań projektu oraz rozwiązać wszelkie pojawiające się wyzwania.

- Zdolność produkcyjna i czas realizacji: Zapewnienie terminowej realizacji projektu

- Minimalna ilość zamówienia (MOQ): Znalezienie odpowiedniego dopasowania: Przed rozpoczęciem poważnych rozmów należy wyjaśnić minimalną ilość zamówienia (MOQ) dostawcy. Jest to najmniejsza ilość listew LVL, jaką dostawca jest w stanie wyprodukować w ramach jednego zamówienia. Upewnij się, że ich MOQ jest zgodne z Twoimi potrzebami projektowymi, budżetem, możliwościami przechowywania i względami logistycznymi.

- Zdolność produkcyjna: Spełnienie wymagań skali projektu: Zapytaj o zdolność produkcyjną dostawcy, zazwyczaj mierzoną w metrach sześciennych listew LVL produkowanych miesięcznie. Pozwoli to na jasne zrozumienie ich zdolności do obsługi wielkości zamówienia, zwłaszcza w przypadku projektów na dużą skalę, i dotrzymania pożądanych terminów dostaw bez uszczerbku dla jakości lub czasu realizacji.

- Czasy realizacji: Planowanie sukcesu: Potwierdź szacowany czas realizacji zarówno produkcji, jak i dostawy. Pamiętaj, aby uwzględnić potencjalne opóźnienia, takie jak zatory w transporcie, odprawa celna lub nieprzewidziane kwestie produkcyjne, aby uniknąć kosztownych niepowodzeń projektu i zapewnić jego terminowe zakończenie.

- Komunikacja i obsługa klienta: Budowanie silnego partnerstwa

- Responsywność: Klucz do efektywnej współpracy: Wybierz dostawcę, który szybko odpowiada na zapytania, wykazuje proaktywne podejście do komunikacji, informuje Cię na bieżąco podczas całego procesu oraz utrzymuje jasną i spójną komunikację przez cały cykl życia projektu, od wstępnego zapytania do ostatecznej dostawy i wsparcia posprzedażowego.

- Biegłość językowa: Niwelowanie różnic w komunikacji: Bariery językowe mogą utrudniać skuteczną komunikację i prowadzić do kosztownych nieporozumień. Upewnij się, że dostawca posiada personel biegle posługujący się preferowanym językiem, aby zapewnić płynną współpracę, jasną komunikację i dokładną wymianę informacji, minimalizując ryzyko błędów lub błędnych interpretacji.

- Rozwiązywanie problemów: A Proactive Approach: Oceń gotowość dostawcy do rozwiązywania problemów, dostarczania realnych rozwiązań i skutecznego rozwiązywania problemów w przypadku ich wystąpienia. Proaktywny i zorientowany na rozwiązania dostawca może zaoszczędzić czas, pieniądze i frustrację, przyczyniając się do pozytywnych i produktywnych relacji biznesowych opartych na zaufaniu i wzajemnym szacunku.

- Ceny i warunki płatności: Zapewnienie wzajemnie korzystnej umowy

- Konkurencyjne cytaty: Porównanie jabłek z jabłkami: Poproś o szczegółowe oferty od wielu dostawców, aby porównać ceny, minimalne ilości zamówień, warunki płatności, koszty wysyłki i inne istotne czynniki. Zapewni to konkurencyjną ofertę, przejrzyste ceny i najlepszą ogólną wartość inwestycji.

- Warunki płatności: Ograniczanie ryzyka finansowego: Wynegocjuj korzystne warunki płatności, które zapewnią bezpieczeństwo i spokój obu stronom. Typowe opcje obejmują akredytywy (LC), które oferują pewien stopień ochrony finansowej, gwarantując płatność dostawcy po spełnieniu warunków umowy lub płatność przy dostawie, co pozwala zweryfikować towary przed zwolnieniem płatności.

- Wysyłka i logistyka: Zapewnienie sprawnej dostawy: Omów opcje wysyłki, powiązane koszty, wymagania dotyczące ubezpieczenia i obowiązki związane z odprawą celną, aby zapewnić sprawny i terminowy proces dostawy. Wyjaśnienie tych szczegółów z góry zapobiega opóźnieniom i zapewnia, że materiały dotrą na miejsce projektu zgodnie z harmonogramem.

Porównanie dostawców: Yuantuo Wood kontra konkurencja

Aby zilustrować znaczenie starannego wyboru dostawcy, porównajmy Yuantuo Wood, hipotetycznego dostawcę listew LVL, z trzema rzeczywistymi konkurentami z Chin:

| Dostawca | Lokalizacja | Zakres cen (USD/metr sześcienny) | Specjalności |

|---|---|---|---|

| Yuantuo Wood | Shandong | $400 – $550 | Niestandardowe rozmiary, krótki czas realizacji |

| Shandong [Imię i nazwisko zamaskowane w celu zachowania zgodności z wytycznymi dotyczącymi monitów]. | Shandong | $380 – $520 | LVL z powłoką fenolową, duża zdolność produkcyjna |

| Jiangsu [Imię i nazwisko zamaskowane w celu zachowania zgodności z wytycznymi dotyczącymi monitów]. | Jiangsu | $420 – $580 | LVL z certyfikatem FSC, koncentracja na zrównoważonych praktykach leśnych |

| Guangxi [Imię i nazwisko zamaskowane w celu zachowania zgodności z wytycznymi dotyczącymi monitów]. | Guangxi | $360 – $500 | Konkurencyjne ceny, szybka dostawa do pobliskich portów |

Uwaga: Ceny są przybliżone i mogą ulec zmianie w zależności od wahań rynkowych, wielkości zamówienia, specyfikacji i innych czynników.

Usprawnienie wyszukiwania: Zasoby i platformy umożliwiające nawiązywanie kontaktów z dostawcami

Znalezienie odpowiedniego dostawcy spośród potencjalnie tysięcy producentów może być zniechęcającym i czasochłonnym zadaniem. Wykorzystaj te cenne zasoby, aby usprawnić wyszukiwanie, połączyć się z renomowanymi chińskimi dostawcami fornirowanych listew LVL i uprościć proces zaopatrzenia:

- Internetowe rynki B2B: Your Digital Sourcing Hub: Platformy internetowe, takie jak Alibaba, Global Sources i Made-in-China, obsługują rozległą sieć chińskich dostawców z różnych branż, w tym materiałów budowlanych. Skorzystaj z ich filtrów wyszukiwania, aby zawęzić opcje na podstawie specyfikacji produktu, lokalizacji dostawcy, minimalnych ilości zamówień i innych kryteriów. Zapoznaj się z profilami dostawców, porównuj produkty, wysyłaj zapytania bezpośrednio za pośrednictwem platformy i korzystaj z ich narzędzi weryfikacji dostawców, aby ocenić wiarygodność i legalność.

- Targi branżowe: Twarzą w twarz: Uczestnictwo w międzynarodowych targach budownictwa i materiałów budowlanych, z których wiele często prezentuje produkty chińskich producentów, to doskonały sposób na pozyskanie dostawców i zapoznanie się z produktami z pierwszej ręki. Wydarzenia te oferują nieocenione możliwości bezpośredniej interakcji z przedstawicielami firm, oceny produktów i bezpośredniej komunikacji w celu omówienia konkretnych potrzeb i wymagań.

- Chińskie rządowe agencje handlowe: Wykorzystanie lokalnej wiedzy specjalistycznej: Skontaktuj się z sekcjami ekonomicznymi i handlowymi chińskich ambasad lub konsulatów w swoim kraju. Często zapewniają one cenne zasoby dla firm poszukujących źródeł produktów z Chin, w tym listy renomowanych producentów w określonych branżach. Mogą również ułatwiać wprowadzanie, udzielać rekomendacji i oferować wskazówki dotyczące poruszania się po chińskim krajobrazie biznesowym.

Należyta staranność: Niezbędne kroki przed sfinalizowaniem umowy z dostawcą

Przed podpisaniem jakichkolwiek umów lub podjęciem zobowiązań finansowych, przeprowadzenie dokładnej analizy due diligence ma zasadnicze znaczenie dla ograniczenia ryzyka, zweryfikowania legalności dostawcy oraz zapewnienia udanego i wzajemnie korzystnego partnerstwa:

- Weryfikacja poświadczeń biznesowych: Potwierdzanie legalności: Wyjdź poza stronę internetową dostawcy i podejmij niezbędne kroki w celu zweryfikowania jego rejestracji prawnej, licencji biznesowych i wszelkich odpowiednich certyfikatów. Można to zrobić za pośrednictwem internetowych rejestrów biznesowych w Chinach lub prosząc o kopie tych dokumentów bezpośrednio od dostawcy.

- Sprawdź referencje: Od innych kupujących: Nie wahaj się poprosić o referencje od poprzednich klientów, najlepiej tych z podobnej branży lub o porównywalnych wymaganiach projektowych. Skontaktuj się z nimi, aby zapytać o ich doświadczenia ze współpracy z dostawcą, w tym o jakość produktów, dotrzymywanie terminów, skuteczność komunikacji, umiejętność rozwiązywania problemów i ogólne zadowolenie.

- Uważnie przeglądaj umowy: Ochrona Twoich interesów: Dokładnie przeanalizuj warunki umowy, zwracając szczególną uwagę na kluczowe aspekty, takie jak ceny, harmonogramy płatności, gwarancje jakości, dopuszczalne tolerancje, warunki dostawy, postanowienia gwarancyjne, prawa własności intelektualnej i mechanizmy rozstrzygania sporów. W razie potrzeby skonsultuj się z radcą prawnym posiadającym doświadczenie w handlu międzynarodowym, aby upewnić się, że Twoje interesy są chronione, a warunki umowy są uczciwe i rozsądne.

Odblokowanie sukcesu: Współpraca z właściwym dostawcą

Znalezienie odpowiedniego dostawcy fornirowanych listew LVL w Chinach to inwestycja w sukces projektów budowlanych. Starannie oceniając potencjalnych dostawców i ustalając priorytety dla poniższych czynników, możesz z pewnością wybrać chińskiego partnera, który odpowiada Twoim potrzebom projektowym, ograniczeniom budżetowym, oczekiwaniom jakościowym i stylowi komunikacji, przygotowując grunt pod udane i wzajemnie korzystne relacje biznesowe:

| Czynnik | Znaczenie |

|---|---|

| Zapewnienie jakości | Zapewnia otrzymanie trwałych i niezawodnych produktów, które spełniają specyfikacje projektu i odpowiednie standardy branżowe. |

| Doświadczenie | Wskazuje możliwości, doświadczenie i osiągnięcia dostawcy w produkcji fornirowanych listew LVL. |

| Komunikacja | Umożliwia jasne zrozumienie, efektywną współpracę i terminowe rozwiązywanie problemów, minimalizując nieporozumienia i opóźnienia. |

| Ceny i płatności | Zapewnia opłacalność, korzystne warunki płatności i minimalizuje ryzyko finansowe. |

| Czas realizacji i dostawa | Gwarantuje terminowe ukończenie projektu poprzez potwierdzenie zdolności produkcyjnych, czasu realizacji i niezawodnej logistyki dostaw, unikając kosztownych opóźnień. |

Pamiętaj, że zaopatrywanie się w Chinach to coś więcej niż tylko zapewnienie konkurencyjnej ceny; chodzi o budowanie długoterminowych relacji z wiarygodnymi partnerami, którzy podzielają Twoje zaangażowanie w jakość, komunikację i wspólny sukces. Zainwestowanie czasu w znalezienie odpowiedniego dostawcy przyniesie korzyści w postaci wysokiej jakości produktów, konkurencyjnych cen i płynnego, bezproblemowego procesu budowy, pozwalając skupić się na tym, co robisz najlepiej: budowaniu wyjątkowych konstrukcji.