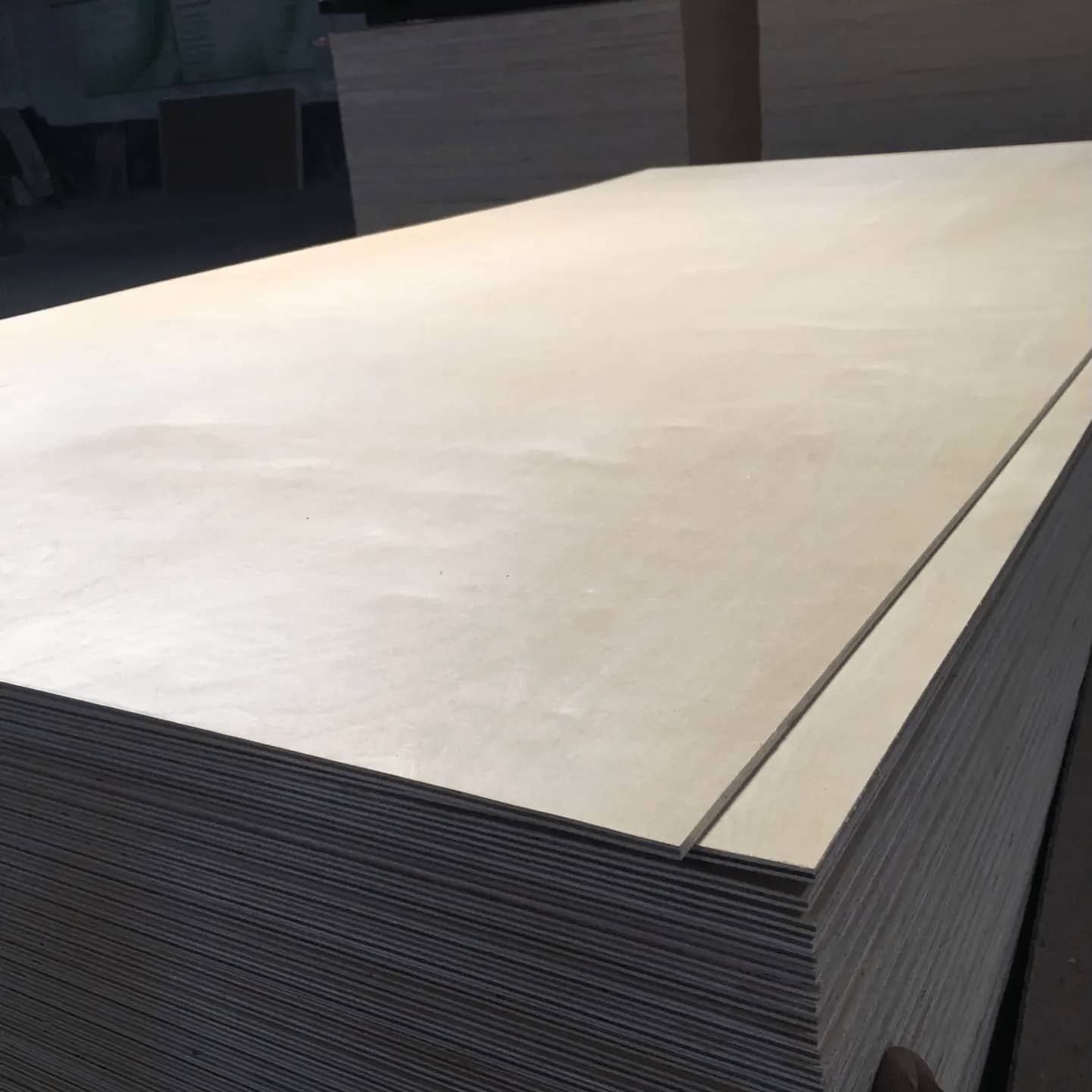

W świecie logistyki i spedycji liczy się pierwsze wrażenie, ale jeszcze ważniejsza jest trwała ochrona. To właśnie tutaj pakowanie sklejka zajmuje centralne miejsce. To niedoceniany bohater, cichy strażnik, zapewniający, że cenne towary dotrą do miejsca przeznaczenia bezpieczne, zdrowe i gotowe do błyszczenia, niezależnie od tego, czy wysyłasz delikatną elektronikę, ciężkie maszyny, czy cokolwiek pomiędzy.

Jednak nie każda sklejka do pakowania jest sobie równa. Potrzebujesz dostawcy, który rozumie znaczenie wytrzymałości, trwałości i opłacalności, partnera, który pomoże Ci dostarczyć produkty w nieskazitelnym stanie, za każdym razem. I tu właśnie wkraczają Chiny, oferując zwycięskie połączenie jakości i przystępnej ceny.

Dlaczego Chiny do pakowania sklejki? Rozpakowywanie zalet

Chiny stały się potęgą w branży sklejki, a sklejka do pakowania nie jest wyjątkiem. Oto dlaczego doświadczone firmy na całym świecie, od małych startupów po międzynarodowe korporacje, zwracają się do Chin w celu zaspokojenia swoich potrzeb w zakresie sklejki do pakowania:

- Ekonomiczne rozwiązania: Korzystaj z konkurencyjnych cen bez uszczerbku dla jakości. Chińscy producenci wykorzystują wydajne procesy produkcyjne, łatwo dostępne surowce i ekonomię skali, aby oferować przyjazne dla budżetu rozwiązania, które nie rozbiją banku, pozwalając ci mądrze alokować swoje zasoby.

- Wyjątkowa wytrzymałość i trwałość: Chińska sklejka do pakowania słynie z solidnej konstrukcji, która jest w stanie wytrzymać rygory transportu i obsługi, w tym wibracje, uderzenia oraz zmiany wilgotności i temperatury. Od ciężkich maszyn po delikatną elektronikę, Twoje produkty będą dobrze chronione podczas całej podróży, minimalizując ryzyko uszkodzeń i kosztownych zwrotów.

- Wszechstronność w najlepszym wydaniu: Niezależnie od tego, czy potrzebujesz arkuszy o standardowych rozmiarach do skrzyń i pudeł, czy też niestandardowych paneli do unikalnych rozwiązań opakowaniowych, chińscy dostawcy oferują szeroką gamę opcji spełniających Twoje specyficzne wymagania. Od prostych palet po skomplikowane skrzynie, chińska sklejka do pakowania może być dostosowana do różnych rozmiarów, kształtów i wagi produktów.

Poruszanie się po dżungli opakowań: Kluczowe czynniki przy wyborze dostawcy

Mnogość dostawców sklejki do pakowania w Chinach sprawia, że znalezienie idealnego partnera dla swojej firmy wymaga starannego rozważenia. Oto przewodnik po procesie selekcji i zabezpieczeniu niezawodnego partnera dla potrzeb sklejki do pakowania:

- Jakość, która mówi sama za siebie:

- Sprawy materialne: Rodzaj drewna użytego do produkcji sklejki znacząco wpływa na jej wytrzymałość, trwałość i odporność na wilgoć. Popularne wybory obejmują:

- Topola: Lekkie i ekonomiczne, idealne do ogólnych zastosowań opakowaniowych, w których ekstremalna wytrzymałość nie jest najważniejsza.

- Drewno liściaste: Oferuje doskonałą wytrzymałość i trwałość, nadaje się do ciężkich opakowań, wysyłki na duże odległości i produktów wymagających solidnej ochrony.

- Sklejka łączona: Łączy różne gatunki drewna, aby zoptymalizować wytrzymałość, wagę i opłacalność, zapewniając zrównoważone rozwiązanie dla różnych potrzeb w zakresie opakowań.

- Nie oszczędzaj na kleju: Klej stosowany do pakowania sklejki ma kluczowe znaczenie dla jej integralności strukturalnej, zwłaszcza w wilgotnym środowisku lub podczas wahań temperatury. Poszukaj dostawców stosujących wysokiej jakości, odporne na wilgoć kleje (takie jak WBP - Weather and Boil Proof), aby zapobiec rozwarstwieniu i zapewnić długotrwałą wydajność, nawet w trudnych warunkach.

- Liczy się gładkość powierzchni: Gładka powierzchnia ma zasadnicze znaczenie dla zapobiegania uszkodzeniom delikatnych produktów podczas transportu i zapewnienia profesjonalnego wyglądu po dostarczeniu. Zapytaj o procesy szlifowania i wykańczania stosowane przez dostawcę, określając pożądany poziom gładkości w oparciu o wrażliwość produktu.

- Sprawy materialne: Rodzaj drewna użytego do produkcji sklejki znacząco wpływa na jej wytrzymałość, trwałość i odporność na wilgoć. Popularne wybory obejmują:

- Doświadczenie, które ma moc:

- Znajomość branży: Poszukaj dostawców z udokumentowanym doświadczeniem w dostarczaniu sklejki do pakowania dla różnych branż, wykazując ich zrozumienie różnorodnych wymagań dotyczących opakowań. Doświadczenie jest równoznaczne z dogłębnym zrozumieniem konkretnych wyzwań związanych z pakowaniem i zdolnością do oferowania dostosowanych rozwiązań, niezależnie od tego, czy wysyłasz delikatne wyroby szklane, czy ciężkie maszyny.

- Opinie klientów są na wagę złota: Nie wahaj się poprosić o referencje klientów lub studia przypadków. Usłyszenie o pozytywnych doświadczeniach innych firm, zwłaszcza tych z Twojej branży, może dostarczyć cennych informacji na temat niezawodności dostawcy, jakości produktów i zdolności do dotrzymywania terminów.

- Poza sklejką:

- Jasna komunikacja jest kluczowa: Wybierz dostawcę, który priorytetowo traktuje jasną, szybką i profesjonalną komunikację, zapewniając, że Twoje wymagania są zrozumiałe, a wszelkie pytania lub wątpliwości są szybko rozwiązywane. Bariery językowe nigdy nie powinny utrudniać transakcji biznesowych, więc szukaj dostawców z anglojęzycznym personelem lub dedykowanymi kanałami komunikacji.

- Doświadczenie w logistyce: Poruszanie się po międzynarodowym transporcie może być skomplikowane i wiązać się z przepisami celnymi, dokumentacją i potencjalnymi opóźnieniami. Niezawodny dostawca powinien mieć doświadczenie w obsłudze dokumentacji eksportowej, odprawie celnej i logistyce, zapewniając, że sklejka do pakowania dotrze bezpiecznie i zgodnie z harmonogramem, minimalizując zakłócenia w łańcuchu dostaw.

Pakowanie dla sukcesu: Składanie zamówień

Po znalezieniu idealnego dostawcy nadchodzi czas na spakowanie zamówienia ze wszystkimi niezbędnymi elementami, zapewniając płynny i wydajny proces zaopatrzenia:

- Szczegółowe specyfikacje: Zapewniamy jasne i kompleksowe specyfikacje dotyczące potrzeb w zakresie sklejki do pakowania, nie pozostawiając miejsca na niejasności. Obejmuje to:

- Gatunki drewna: Określ żądany gatunek drewna w oparciu o wymagania dotyczące opakowania, budżet oraz wymagany poziom wytrzymałości i odporności na wilgoć.

- Grubość i wymiary: Zapewniamy precyzyjne pomiary, aby zminimalizować ilość odpadów i zapewnić idealne dopasowanie do projektów opakowań, zmniejszając potrzebę modyfikacji na miejscu i potencjalne opóźnienia.

- Rodzaj kleju: Określ żądany rodzaj kleju, upewniając się, że spełnia on wymagania dotyczące odporności na wilgoć i trwałości, szczególnie w przypadku wysyłki do wilgotnych środowisk lub przechowywania produktów przez dłuższy czas.

- Wykończenie powierzchni: Wskaż wszelkie pożądane wykończenia powierzchni, takie jak szlifowanie lub powlekanie, aby uzyskać pożądaną gładkość i poziom ochrony dla określonych produktów.

- Ilość i termin dostawy: Wyraźnie poinformuj o żądanej ilości i oczekiwanych ramach czasowych dostawy, aby upewnić się, że dostawca może dotrzymać harmonogramu produkcji i uniknąć kosztownych opóźnień. Bądź realistą, jeśli chodzi o terminy i zapytaj o zdolności produkcyjne dostawcy i czas realizacji.

- Warunki płatności & Warunki: Ustalenie jasnych warunków płatności, w tym metod płatności, wymagań dotyczących depozytu oraz wszelkich obowiązujących należności celnych przywozowych lub podatków. Omów zabezpieczenie płatności i upewnij się, że obie strony są zadowolone z warunków przed sfinalizowaniem zamówienia.

Rozpakowywanie opcji: Znajdowanie dostawcy

Znalezienie odpowiedniego dostawcy sklejki do pakowania w Chinach nie musi być logistycznym koszmarem. Oto zestawienie typowych metod pozyskiwania, z których każda ma swoje zalety i wady, aby pomóc w poruszaniu się po tym procesie:

| Metoda | Plusy | Wady |

|---|---|---|

| Internetowe platformy B2B: | Wygodny, szeroki wybór dostawców, dostęp do ocen i recenzji dostawców, często wbudowane narzędzia komunikacyjne, pozwalają na łatwe porównywanie zakupów. | Może być przytłaczający w nawigacji, potencjał oszustw, poleganie na komunikacji online, ograniczona możliwość interakcji osobistej, może wymagać dodatkowej należytej staranności w celu weryfikacji dostawców. |

| Targi: | Możliwość spotkania się z dostawcami twarzą w twarz, zobaczenia próbek produktów z pierwszej ręki, nawiązania kontaktów z profesjonalistami z branży, zdobycia cennych informacji rynkowych | Wymaga podróży, ogranicza się do określonych okresów w roku, może wymagać znacznego planowania i wydatków, nie wszyscy odpowiedni dostawcy mogą uczestniczyć w każdych targach. |

| Agenci zaopatrzenia: | Doświadczenie w poruszaniu się po rynku chińskim, może obsługiwać zaopatrzenie i logistykę, może zapewnić pomoc językową, może zaoszczędzić czas i wysiłek, może pomóc w ograniczeniu ryzyka. | Dodatkowe koszty, potencjalne luki w komunikacji między klientem a dostawcą, konieczność dokładnej weryfikacji w celu znalezienia renomowanego agenta, rezygnacja z części kontroli nad procesem pozyskiwania. |

Dostarczamy doskonałość: Często zadawane pytania dotyczące pakowania sklejki z Chin

1. Jakie są typowe zastosowania sklejki do pakowania?

Wszechstronność sklejki do pakowania sprawia, że jest to najlepszy wybór w różnych branżach i zastosowaniach, w tym:

- Skrzynie i pudełka: Tworzymy solidne i niezawodne kontenery transportowe dla szerokiej gamy towarów, od delikatnych przedmiotów po ciężkie maszyny.

- Palety: Zapewnia stabilną podstawę do układania i transportu towarów, zapewniając sprawny załadunek i rozładunek oraz minimalizując ryzyko uszkodzenia podczas transportu.

- Kontenery transportowe: Wzmocnienie i ochrona towarów w kontenerach transportowych, szczególnie w przypadku transportu na duże odległości lub transportu towarów podatnych na wilgoć lub uderzenia.

- Niestandardowe rozwiązania w zakresie opakowań: Tworzenie dostosowanych rozwiązań opakowaniowych dla unikalnych lub delikatnych przedmiotów, zapewniających dokładne dopasowanie i optymalną ochronę podczas transportu.

2. Jaki jest koszt pakowania sklejki z Chin w porównaniu z innymi opcjami zaopatrzenia?

Chińska sklejka do pakowania jest generalnie bardziej opłacalna niż sklejka z innych regionów ze względu na zbieżność czynników, w tym wydajne procesy produkcyjne, niższe koszty pracy, łatwo dostępne surowce i konkurencyjny rynek.

3. Czy mogę poprosić o niestandardowe rozmiary i grubości sklejki do pakowania?

Tak, wielu chińskich dostawców jest dobrze przygotowanych do obsługi zamówień niestandardowych, umożliwiając zamawianie sklejki do pakowania w określonych rozmiarach i grubościach, aby spełnić unikalne wymagania dotyczące pakowania. Ta elastyczność zapewnia idealne dopasowanie do produktów, zmniejszając ilość odpadów i optymalizując ochronę.

4. Jaki jest typowy czas realizacji zamówienia sklejki opakowaniowej z Chin?

Czas oczekiwania na sklejkę do pakowania z Chin może różnić się w zależności od kilku czynników, w tym wielkości zamówienia, wymagań dotyczących personalizacji, zdolności produkcyjnych dostawcy i wybranej metody wysyłki. Ważne jest, aby z góry jasno określić pożądane ramy czasowe dostawy i zapytać dostawcę o szacowany czas realizacji, aby uniknąć potencjalnych opóźnień.

5. Na jakie certyfikaty należy zwrócić uwagę przy wyborze dostawcy sklejki do pakowania?

Chociaż konkretne certyfikaty dotyczące sklejki do pakowania mogą się różnić, priorytetowo należy traktować dostawców z certyfikatem ISO 9001, potwierdzającym przestrzeganie przez nich uznanych na całym świecie systemów zarządzania jakością. Ponadto należy zapytać o ich zaangażowanie w standardy środowiskowe, odpowiedzialne praktyki leśne i wszelkie odpowiednie certyfikaty branżowe, aby zapewnić etyczne i zrównoważone pozyskiwanie.

Dlaczego warto wybrać Yuantuo Wood do pakowania sklejki?

Rozumiemy znaczenie niezawodna, wysokiej jakości sklejka do pakowania w zapewnieniu, że produkty dotrą do miejsca przeznaczenia w nieskazitelnym stanie. W Yuantuo Wood wykraczamy poza zwykłe dostarczanie sklejki; zapewniamy spokój ducha.

Oto dlaczego Yuantuo Wood jest idealnym partnerem do pakowania sklejki z Chin:

- Niezachwiane zaangażowanie w jakość: Naszą sklejkę pozyskujemy od zaufanych producentów, dla których priorytetem jest wytrzymałość, trwałość i precyzyjne specyfikacje.

- Dostosowane rozwiązania dla Twojego sukcesu: Niezależnie od tego, czy potrzebujesz standardowych rozmiarów, czy niestandardowych cięć, określonych gatunków drewna lub unikalnych wykończeń powierzchni, będziemy współpracować z Tobą, aby spełnić Twoje dokładne wymagania.

- Doświadczenie i wiedza, którym można zaufać: Nasz zespół posiada dogłębną wiedzę na temat branży sklejki opakowaniowej, dzięki czemu otrzymujesz fachowe wskazówki i wsparcie w trakcie całego procesu.

- Przejrzysta komunikacja na każdym kroku: Wierzymy w otwartą, jasną komunikację, informowanie o postępach w realizacji zamówienia i szybkie odpowiadanie na wszelkie pytania.

- Konkurencyjne ceny i terminowość dostaw: Oferujemy konkurencyjne ceny na naszą sklejkę do pakowania i ściśle współpracujemy z klientem, aby zapewnić terminową dostawę, utrzymując płynność łańcucha dostaw.

Nawiąż współpracę z Yuantuo Wood i doświadcz różnicy, jaką jakość, niezawodność i wyjątkowa obsługa mogą wnieść do Twoich operacji pakowania. Skontaktuj się z nami już dziś, aby omówić swoje potrzeby w zakresie sklejki do pakowania!

Pakowanie: Podsumowanie

Wybór odpowiedniego dostawcy sklejki do pakowania ma kluczowe znaczenie dla ochrony produktów, kontrolowania kosztów i zapewnienia płynnych operacji wysyłkowych. Starannie rozważając swoje potrzeby, przeprowadzając dokładne badania i współpracując z renomowanym dostawcą w Chinach, możesz pakować swoje produkty z pewnością, wiedząc, że dotrą do miejsca przeznaczenia w nieskazitelnym stanie, gotowe wywrzeć trwałe wrażenie. Pamiętaj, że inwestycja w wysokiej jakości sklejkę do pakowania to inwestycja w bezpieczną i wydajną dostawę produktów, a ostatecznie w zadowolenie klientów.