In the realm of furniture design and construction, the quest for materials that deliver unwavering strength, unwavering stability, and unwavering reliability is never-ending. As manufacturers strive to meet the demands of discerning customers – customers who expect furniture that not only looks good but also withstands the rigors of daily life – engineered wood products have emerged as game-changers. Among these innovations, Engineered Veneer LVL (Laminated Veneer Lumber) slats stand out as a testament to engineering ingenuity, offering a potent blend of strength, versatility, and sustainability that’s captivating furniture makers and revolutionizing the industry.

But what exactly are LVL slats, and how are they transforming the furniture industry from the inside out? Let’s delve into the world of LVL slat applications, uncovering the reasons behind their growing popularity and exploring the diverse ways they’re being used to craft furniture that stands the test of time, exceeding customer expectations and setting new standards for durability.

What Makes Engineered Veneer LVL Slats a Cut Above?

Before we dive into the exciting world of LVL slat applications, let’s take a closer look at what makes them such a compelling choice for furniture makers, setting them apart from traditional materials and solidifying their position as a superior solution:

- Engineered for Strength, Designed for Excellence: LVL slats are not merely cut from wood; they are meticulously engineered for strength. The process involves bonding thin layers of wood veneer together under carefully controlled heat and pressure. The secret to their exceptional strength lies in the arrangement of these layers – the grain of each layer runs in alternating directions, a technique known as cross-graining. This strategic layering distributes strength evenly across the entire slat, resulting in a product that’s significantly stronger and more resistant to bending, warping, and breaking than traditional solid wood.

- Dimensional Stability: The Antidote to Warping and Twisting: One of the biggest challenges with solid wood is its tendency to expand and contract with changes in humidity. This natural movement can lead to warping, twisting, and cracking over time, compromising the structural integrity and aesthetic appeal of furniture. LVL slats, however, are engineered to overcome this challenge. Their manufacturing process minimizes wood’s natural tendency to react to moisture, resulting in exceptional dimensional stability. This means furniture built with LVL slats is far less likely to warp, twist, or crack over time, even in environments with fluctuating humidity levels, ensuring that it maintains its structural integrity and visual appeal for years to come.

- Consistency is Key: The Assurance of Quality: Natural wood, while beautiful, is inherently inconsistent. Each piece can have knots, grain variations, and other inconsistencies that affect its strength, stability, and workability. This variability introduces uncertainty into the manufacturing process and can lead to inconsistencies in the final product. LVL slats, on the other hand, are manufactured under controlled conditions, ensuring consistent quality and performance from slat to slat. This eliminates the guesswork, reduces waste, and allows manufacturers to create furniture with predictable quality and performance.

- Sustainability Matters: A Responsible Choice for a Healthier Planet: As awareness of environmental issues grows, so too does the demand for sustainable building materials. LVL slats align with this eco-conscious shift. They are typically manufactured using veneers from sustainably managed forests, ensuring that the wood is harvested responsibly and that forests are managed for long-term health and productivity. Choosing LVL slats is a step towards reducing the environmental impact of furniture manufacturing and embracing a more sustainable future.

Engineered Veneer LVL Slat Applications: Where Strength Meets Versatility

The exceptional strength-to-weight ratio, dimensional stability, and consistent quality of LVL slats make them ideal for a wide range of furniture applications, catering to the needs of diverse customer bases and design aesthetics:

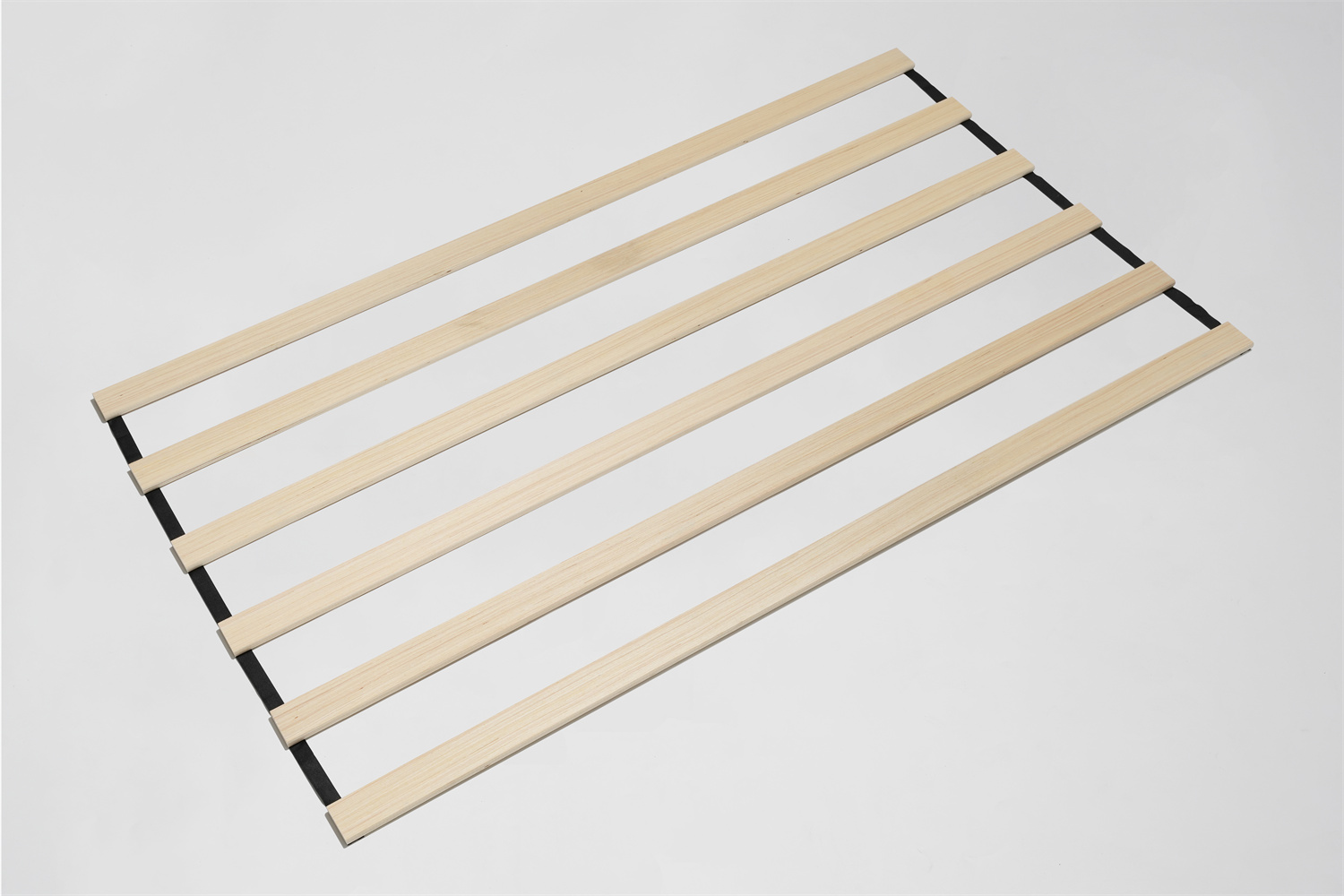

1. Bed Frames: The Foundation of Restful Sleep

LVL slats have emerged as the gold standard for supporting mattresses in bed frames, particularly in models designed for durability, heavy use, and premium sleep experiences. Their remarkable ability to withstand weight and resist sagging, even under pressure, ensures a comfortable and supportive sleep surface that promotes proper spinal alignment and restful sleep.

- Target Audience:

- Mattress Manufacturers: Seeking to enhance the performance and longevity of their mattresses by pairing them with supportive, durable bed frames.

- Furniture Makers: Specializing in high-end bedroom furniture where quality, durability, and customer satisfaction are paramount.

- Consumers: Investing in premium mattresses and seeking bed frames that provide optimal support and extend the lifespan of their investment.

- Advantages in Bed Frames:

- Prevents Mattress Sagging, Extending Mattress Lifespan: LVL slats provide consistent, even support across the entire sleep surface, preventing mattresses from sagging over time and extending their lifespan.

- Provides Even Weight Distribution for Optimal Support: The strength and stability of LVL slats ensure that weight is distributed evenly across the bed frame, providing optimal support for the mattress and the sleeper.

- Handles the Demands of Heavier Mattresses: LVL slats are particularly well-suited for supporting heavier mattresses, such as those made with memory foam, latex, or hybrid materials, which require a more robust foundation than traditional innerspring mattresses.

- Offers Consistent Support Across the Entire Sleep Surface: Unlike some bed frame supports that can create pressure points or uneven support, LVL slats provide consistent support across the entire sleep surface, promoting proper spinal alignment and a more comfortable sleep experience.

2. Sofa Frames: Built for Comfort and Durability

In the world of sofas, durability and long-lasting comfort are paramount. LVL slats provide the robust foundation needed for sturdy and long-lasting sofa frames, capable of withstanding the rigors of daily use and maintaining their structural integrity for years to come.

- Target Audience:

- Upholstered Furniture Manufacturers: Seeking to create high-quality sofas that provide exceptional support, comfort, and longevity.

- Commercial Furniture Makers: Supplying sofas for high-traffic areas such as hotels, lobbies, and waiting rooms, where durability is essential.

- Consumers: Investing in sofas that are built to last, providing both comfort and long-term value.

- Advantages in Sofa Frames:

- Withstands Heavy Use and Resists Sagging: LVL slats can handle the weight of multiple sitters and resist sagging or warping over time, ensuring that sofas maintain their shape and comfort even with frequent use.

- Maintains the Structural Integrity of the Sofa Over Time: The inherent strength and stability of LVL slats help maintain the structural integrity of the sofa frame, preventing it from becoming loose, wobbly, or unstable over time.

- Ensures Consistent Support for Cushions and Upholstery: LVL slats provide a consistent, even surface for cushions and upholstery to rest on, preventing sagging, bunching, and uneven wear.

- Ideal for High-Traffic Areas and Commercial Settings: Their durability makes LVL slats particularly well-suited for sofas used in high-traffic areas or commercial settings, where they are subjected to more frequent use and heavier loads.

3. Tabletops and Shelving: Strength for Heavy Loads

Whether it’s a dining table that needs to support the weight of a feast or a bookshelf laden with heavy volumes, LVL slats provide the strength and stability needed to handle heavy loads without compromising on style or design.

- Target Audience:

- Furniture Makers: Crafting high-quality tables, desks, shelves, and other furniture pieces that require a strong and stable foundation.

- Commercial Furniture Manufacturers: Supplying furniture for offices, libraries, retail spaces, and other commercial environments where durability and functionality are crucial.

- DIY Enthusiasts: Seeking robust and reliable materials for building custom furniture pieces that can withstand heavy use.

- Advantages in Tabletops & Shelving:

- Supports Heavy Items Without Sagging or Bowing: LVL slats provide a level, supportive surface that can handle the weight of heavy items without sagging, bowing, or compromising the structural integrity of the furniture piece.

- Maintains a Level Surface for Dining, Working, or Display: Their dimensional stability ensures that tabletops and shelves remain flat and even, providing a stable and reliable surface for dining, working, or displaying items.

- Prevents Warping or Twisting, Ensuring Longevity: LVL slats’ resistance to warping and twisting ensures that tabletops and shelves maintain their shape and functionality over time, even in environments with fluctuating humidity levels.

- Ideal for Dining Tables, Bookshelves, Workbenches, and More: The versatility of LVL slats makes them suitable for a wide range of tabletop and shelving applications, from dining tables and bookshelves to workbenches, retail displays, and more.

4. Cabinet Construction: Reinforcing Strength and Durability

Cabinets, especially those in kitchens and bathrooms, are subjected to heavy use and often carry significant weight. LVL slats provide the reinforcement needed to create cabinets that can handle the demands of daily life without compromising on style or functionality.

- Target Audience:

- Cabinet Makers: Seeking to enhance the strength, durability, and longevity of their cabinets, especially those designed for heavy use or to support heavy items.

- Kitchen and Bathroom Designers: Specifying materials that meet the demanding requirements of kitchen and bathroom environments, where moisture and heavy use are common.

- Homeowners: Investing in high-quality cabinets that are built to last and can withstand the rigors of daily use.

- Advantages in Cabinet Construction:

- Strengthens Cabinet Frames to Prevent Racking and Sagging: LVL slats add rigidity and strength to cabinet frames, preventing them from racking (becoming skewed or misaligned) or sagging under the weight of cabinet doors, drawers, and contents.

- Enables Cabinets to Support Heavier Items Without Compromising Structure: Reinforcing cabinets with LVL slats allows them to support heavier items, such as cookware, appliances, or pantry goods, without compromising their structural integrity.

- Maintains the Alignment of Doors and Drawers Over Time: By preventing racking and sagging, LVL slats help maintain the alignment of cabinet doors and drawers, ensuring smooth operation and a polished look over time.

- Extends the Lifespan of Cabinets, Especially in Heavy-Use Areas: The added durability provided by LVL slats extends the lifespan of cabinets, making them a wise investment for kitchens, bathrooms, and other areas of the home that experience heavy use.

5. Upholstered Furniture: A Supportive Core

Comfort is king in the world of upholstered furniture, and LVL slats play a crucial role in providing the supportive core that enhances comfort and extends the lifespan of upholstered pieces.

- Target Audience:

- Upholstered Furniture Makers: Creating chairs, sofas, ottomans, and other upholstered pieces that prioritize comfort, support, and durability.

- Interior Designers: Seeking high-quality furniture options that meet the ergonomic and aesthetic needs of their clients.

- Consumers: Investing in upholstered furniture that provides both comfort and long-term value.

- Advantages in Upholstered Furniture:

- Provides Consistent Support for Cushions and Padding: LVL slats create a strong, even base for cushions and padding, ensuring that they are properly supported and maintain their shape over time.

- Enhances Comfort and Ergonomics: The consistent support provided by LVL slats contributes to the overall comfort and ergonomics of upholstered furniture, making it more enjoyable to sit on and relax in.

- Extends the Lifespan of Upholstery by Preventing Sagging and Wear: By providing a supportive foundation, LVL slats help prevent cushions and padding from sagging, compressing, or wearing unevenly, extending the lifespan of the upholstery.

- Ideal for Chairs, Sofas, Ottomans, and Other Upholstered Pieces: The versatility of LVL slats makes them suitable for a wide range of upholstered furniture applications, from armchairs and sofas to ottomans, benches, and more.

Choosing the Right LVL Slats: Factors to Consider

Selecting the right LVL slats for your furniture projects is crucial for ensuring optimal performance, durability, and compatibility with your design vision. Here are key factors to consider:

- Slat Dimensions: Finding the Perfect Fit for Your Project: LVL slats are available in a range of widths and thicknesses to accommodate diverse furniture designs and load-bearing requirements. Thicker and wider slats offer greater strength and load-bearing capacity, making them suitable for heavier furniture pieces or applications where structural support is paramount. Consider the intended application, the weight of the furniture piece, and the expected load it will bear when selecting slat dimensions. Consulting load-bearing charts and seeking expert advice can help determine the appropriate dimensions for your specific needs.

- Slat Spacing: Balancing Support and Ventilation: The spacing between slats is a critical consideration that affects both the level of support provided and the breathability of the furniture piece. Closer slat spacing provides firmer support, which is ideal for heavier mattresses, sofas subjected to frequent use, or furniture pieces designed to hold heavy items. Wider spacing, on the other hand, offers more flexibility and ventilation, making it suitable for lighter mattresses, furniture where breathability is essential, or applications where a slight degree of flex is desired.

- Moisture Content: Ensuring Stability in Varying Environments: Wood is a hygroscopic material, meaning it absorbs and releases moisture in response to changes in relative humidity. While LVL slats are engineered for dimensional stability, it’s still essential to choose slats with a moisture content appropriate for the intended use environment. This helps prevent warping or dimensional changes once the furniture is assembled and placed in its final location. For instance, slats intended for humid environments should have a lower moisture content than those used in drier climates. Maintaining a consistent moisture content throughout the manufacturing and installation process is crucial for preventing warping or twisting.

- Supplier Reputation: Partnering with Excellence: The quality and consistency of your LVL slats directly impact the quality and longevity of your furniture. That’s why partnering with a reputable LVL slat supplier with a proven track record of quality and reliability is paramount. Look for suppliers who source their veneers from sustainably managed forests, adhere to stringent manufacturing standards, and have a commitment to customer satisfaction. A reliable supplier will provide technical expertise, assist with product selection, and ensure a smooth procurement process, contributing to the overall success of your furniture project.

Engineered Veneer LVL Slats: A Comparative Look

| Feature | LVL Slats | Solid Wood Slats | Metal Slats |

|---|---|---|---|

| Strength | Exceptional | Good, but varies by species and quality | Excellent, but can be heavy and prone to bending |

| Stability | Superior, engineered to resist warping and twisting | Moderate, susceptible to warping, twisting, and cracking over time | Excellent, but can be noisy and transmit vibrations |

| Consistency | High, manufactured to precise standards for predictable performance | Low, natural variations in wood grain and density can affect strength and stability | High, manufactured to uniform specifications |

| Moisture Resistance | Good, engineered to minimize moisture absorption | Moderate, can warp, swell, or shrink in response to changes in humidity | Excellent, impervious to moisture damage |

| Sustainability | Good, typically made from sustainably sourced veneers | Varies depending on sourcing practices and forest management | Moderate, production can be energy-intensive |

| Cost | Moderate, typically more expensive than solid wood but less expensive than metal | Varies widely depending on wood species, quality, and availability | High, often the most expensive option |

FAQs: Engineered Veneer LVL Slats

1. How do LVL slats compare to traditional wooden slats in terms of cost?

While LVL slats are typically more expensive than traditional solid wood slats upfront, their enhanced durability, longevity, and consistent quality often result in cost savings over time. LVL slats are less likely to warp, sag, or break, reducing the need for repairs or replacements and extending the lifespan of the furniture they support.

2. Can LVL slats be used in outdoor furniture applications?

LVL slats are primarily designed for indoor use. While they offer good moisture resistance, prolonged exposure to the elements can lead to deterioration over time. For outdoor furniture, materials specifically treated for exterior use are recommended.

3. Are LVL slats compatible with adjustable bed frames?

Yes, LVL slats are compatible with many adjustable bed frames. Their strength and stability make them suitable for supporting the weight of the mattress and the adjustable frame mechanism. However, it’s essential to check the manufacturer’s specifications for both the bed frame and the LVL slats to ensure compatibility.

4. What is the typical lifespan of furniture made with LVL slats?

Furniture made with LVL slats is known for its exceptional durability and longevity. With proper care and maintenance, furniture built with LVL slats can last for decades, significantly longer than furniture made with lower-quality materials.

5. Can I cut or modify LVL slats to fit my specific furniture project?

While LVL slats can be cut to size, it’s crucial to follow the manufacturer’s recommendations and use appropriate cutting tools to avoid compromising the structural integrity of the slats. If you have any doubts or require complex modifications, consulting with a professional is recommended.