Every Slat is Crafted with Precision to be Exceptional

Yuantuo Wood: Crafting Quality Bed Slats Manufacturer Since 2014

Specializing in high-quality wooden bed slats and accessories, we are backed by years of experience and international certifications.

Wenan Yuantuo Wood Industry Co., Ltd. was established in 2014. We are specializes in the production of various wooden bed slats and related accessories. After years of development, we have successfully obtained many international certifications such as FSC, EPA and CARB.

Discover Our Offering Category

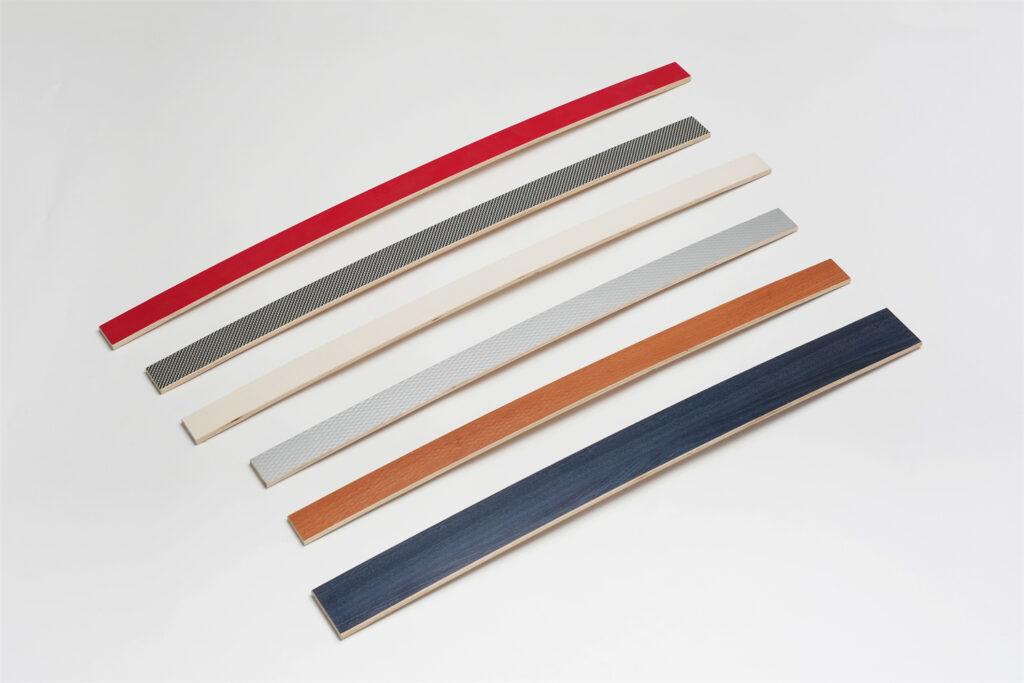

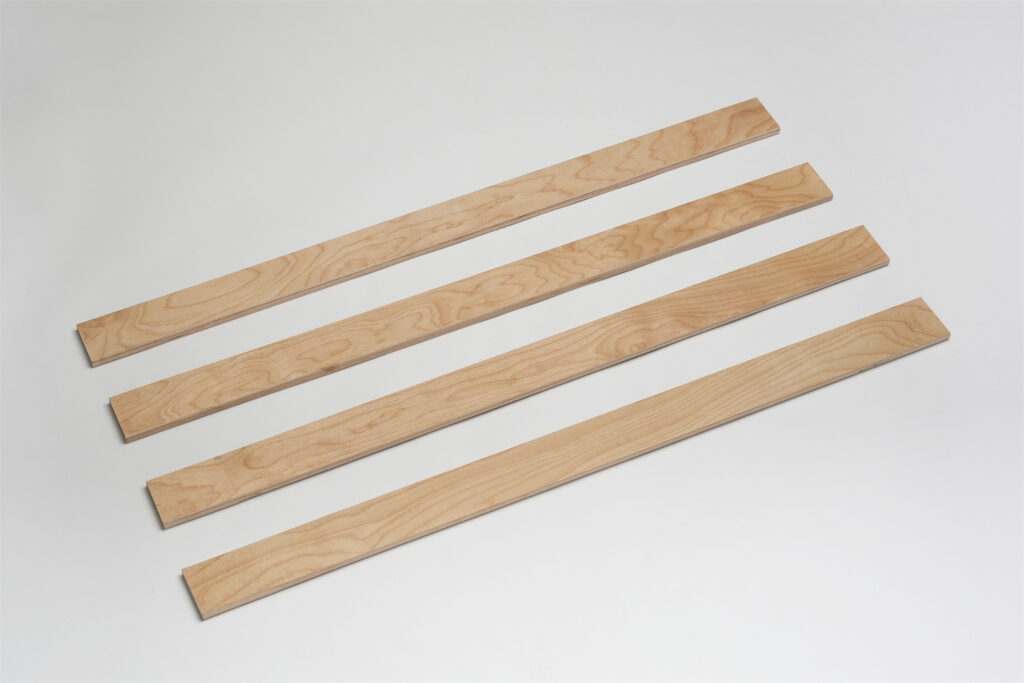

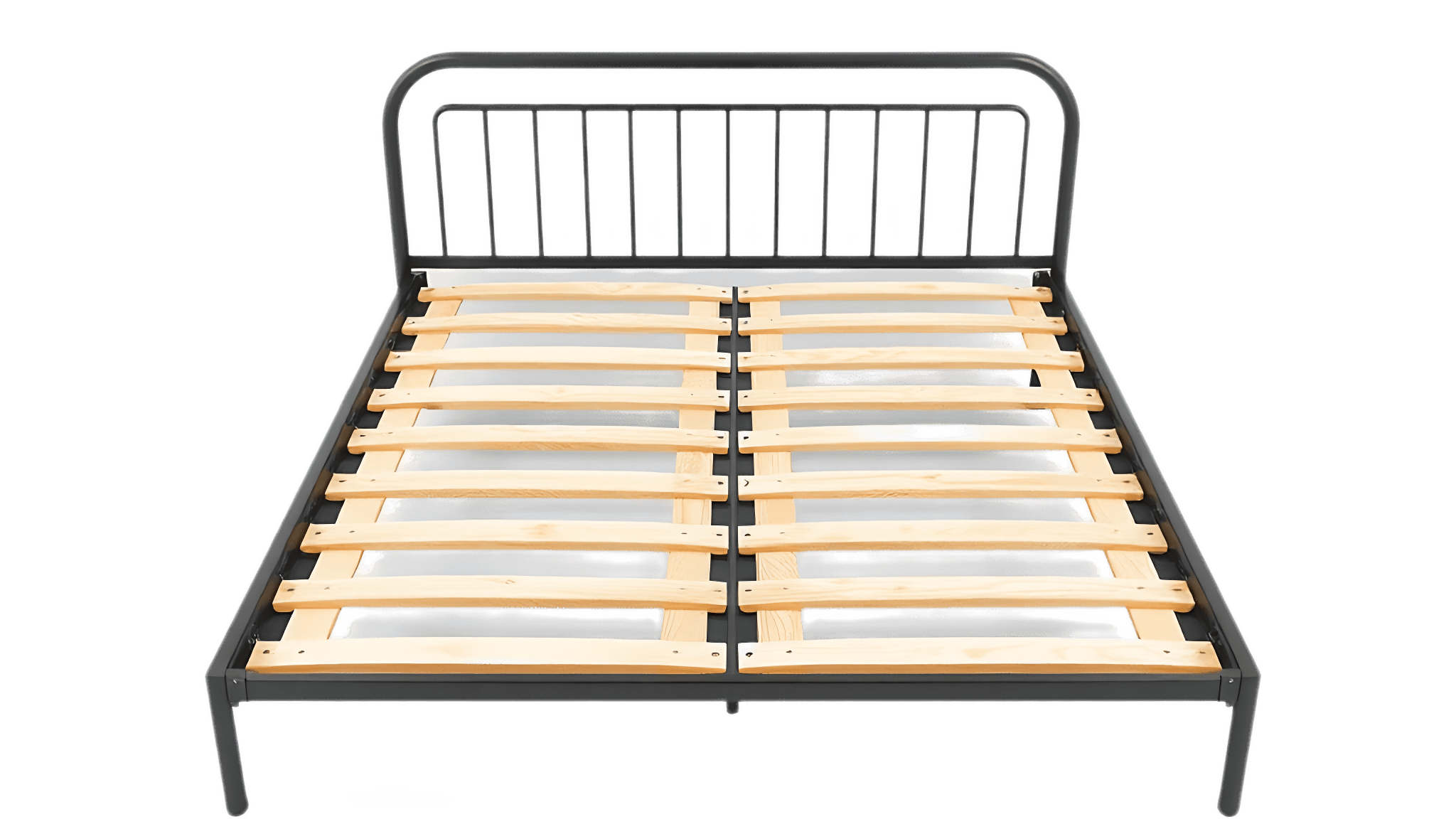

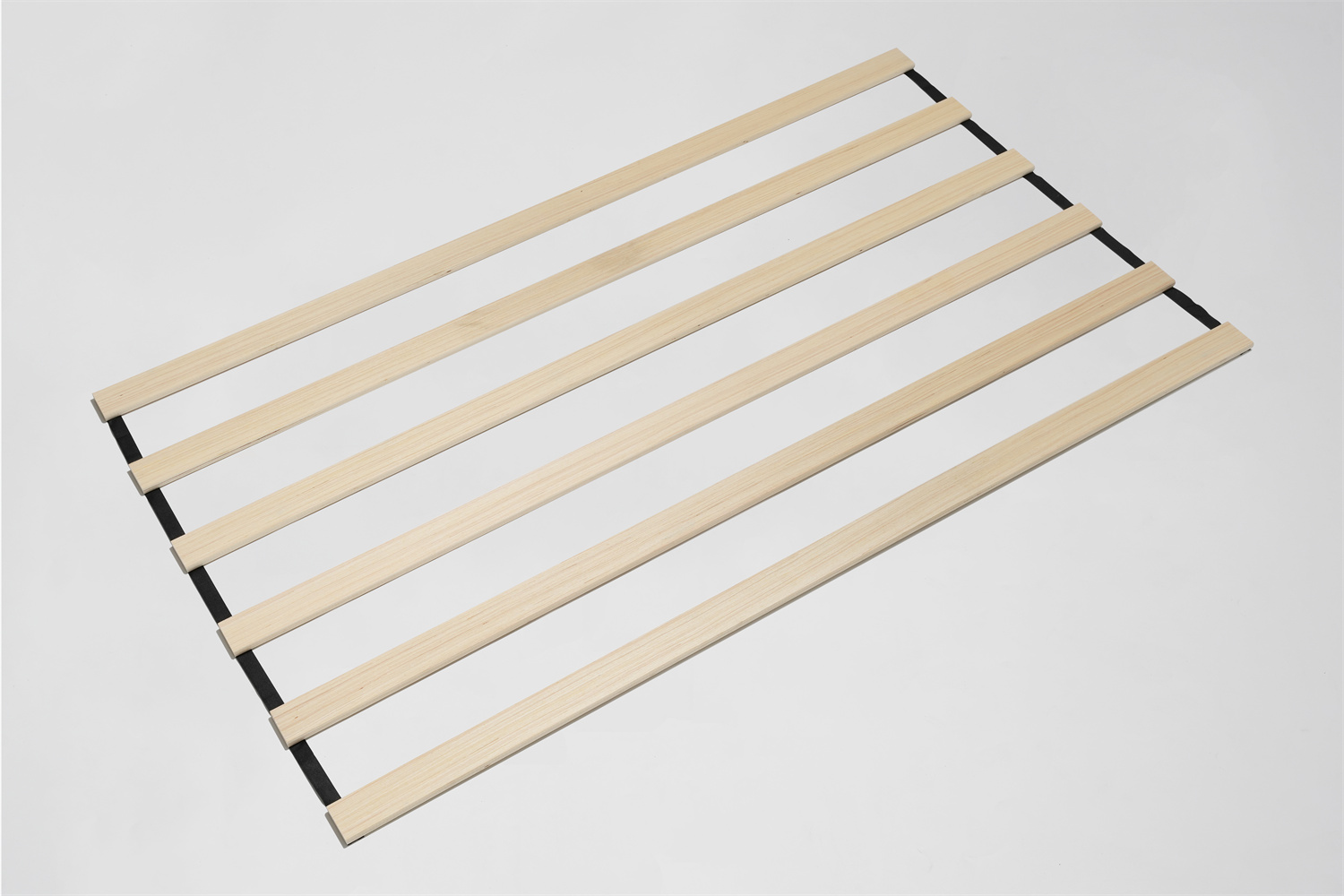

Bed Slats

Yuantuo Wood durable and flexible bed slats designed to provide optimal support and comfort for various bed frames.

LVL Slats

Engineered veneer laminated slats offering enhanced strength and stability, ideal for robust construction and furniture applications.

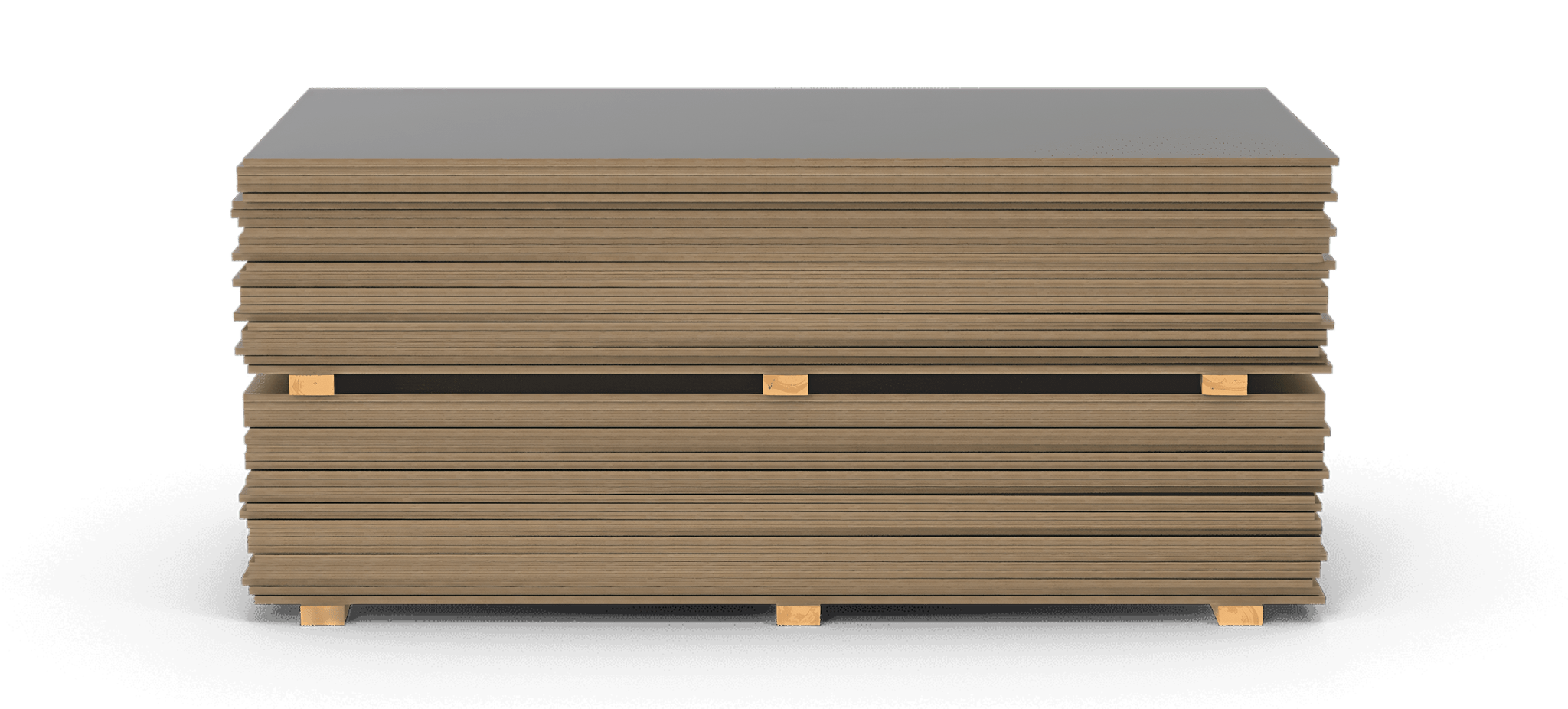

Plywood

High-quality plywood sheets suitable for a wide range of uses, from furniture making to construction and packaging.

Excellence Engineered

The Yuantuo Wood Quality Promise

Rigorous Testing

Each product undergoes thorough testing to ensure it meets our strict quality benchmarks for durability and performance.

Precision Manufacturing

We use advanced machinery and precise techniques to manufacture products that adhere to exact specifications.

Certified Materials

We source only high-quality, certified materials to ensure every component meets industry standards.

Continuous Improvement

Our commitment to quality includes ongoing research and development to enhance our processes and products.

What makes us great

At Yuantuo Wood, we pride ourselves on our dedication to quality and innovation. We combine advanced technology with skilled craftsmanship to ensure that every product meets high standards. Our focus on understanding and addressing your specific needs helps us provide practical solutions that truly make a difference.

Durable

Made from high-quality poplar and birch for lasting strength and resistance to deformation.

Flexible

Available in various sizes and shapes to fit different bed frames and meet specific customer needs.

Blog & News

Stay informed with the latest updates, insights, and stories from Yuantuo Wood. Explore our blog for expert articles on bed slat solutions, industry trends, and company news.